Region:Europe

Author(s):Shubham

Product Code:KRAC0638

Pages:90

Published On:August 2025

By Type:The market is segmented into various types, including Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), Industrial Sensors and Actuators, Industrial Robots and Cobots, Distributed Control Systems (DCS), Supervisory Control and Data Acquisition (SCADA), Machine Vision and Industrial PCs, Industrial Networking & Communication (Fieldbus, Ethernet), Motion Control (Drives, Motors, Servo Systems), and Manufacturing Execution Systems (MES) & Industrial Software. Among these, PLCs remain a widely deployed control layer across discrete and process automation, complemented by growing investments in robotics, industrial networking/Ethernet, machine vision, and MES for data-driven operations and predictive maintenance under Industry 4.0 programs .

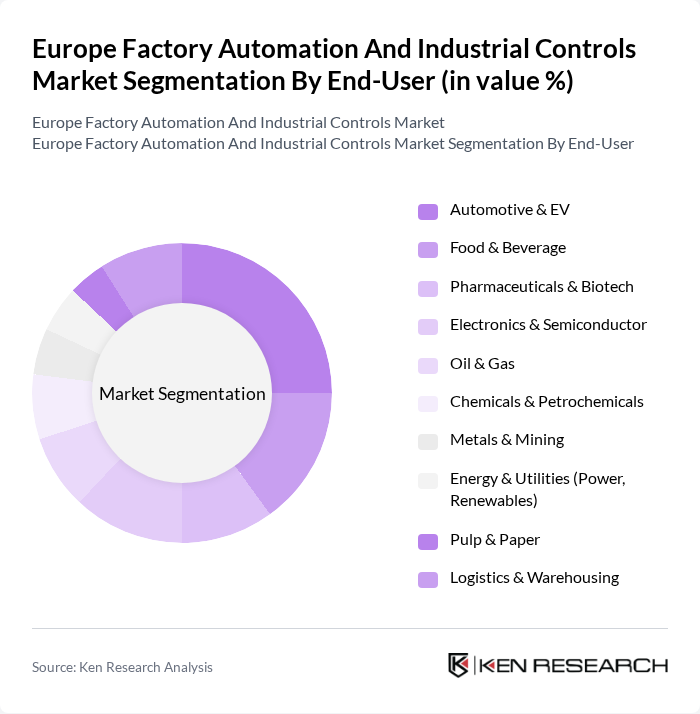

By End-User:The end-user segmentation includes Automotive & EV, Food & Beverage, Pharmaceuticals & Biotech, Electronics & Semiconductor, Oil & Gas, Chemicals & Petrochemicals, Metals & Mining, Energy & Utilities (Power, Renewables), Pulp & Paper, and Logistics & Warehousing. The Automotive & EV sector is a leading end-user in Europe’s automation spend, supported by retooling for EV platforms, battery production, and advanced body-in-white and powertrain automation; F&B and pharmaceuticals continue to invest in hygienic automation, traceability, and regulatory-compliant control systems .

The Europe Factory Automation And Industrial Controls Market is characterized by a dynamic mix of regional and international players. Leading participants such as Siemens AG, Schneider Electric SE, Rockwell Automation, Inc., ABB Ltd., Honeywell International Inc., Mitsubishi Electric Corporation, Emerson Electric Co., Yokogawa Electric Corporation, Bosch Rexroth AG, Omron Corporation, FANUC Corporation, KUKA AG, NI (National Instruments) Corporation, B&R Industrial Automation GmbH (A member of ABB Group), Beckhoff Automation GmbH & Co. KG, WAGO GmbH & Co. KG, Phoenix Contact GmbH & Co. KG, SICK AG, Endress+Hauser Group, Danfoss A/S (Drives) contribute to innovation, geographic expansion, and service delivery in this space.

The future of the Europe factory automation and industrial controls market appears promising, driven by technological advancements and increasing investments in smart manufacturing. As companies prioritize digital transformation, the integration of AI and IoT will enhance operational efficiencies and data-driven decision-making. Furthermore, the emphasis on sustainability and compliance with environmental regulations will shape the development of innovative automation solutions, ensuring that European manufacturers remain competitive in a global market increasingly focused on efficiency and sustainability.

| Segment | Sub-Segments |

|---|---|

| By Type | Programmable Logic Controllers (PLCs) Human-Machine Interfaces (HMIs) Industrial Sensors and Actuators Industrial Robots and Cobots Distributed Control Systems (DCS) Supervisory Control and Data Acquisition (SCADA) Machine Vision and Industrial PCs Industrial Networking & Communication (Fieldbus, Ethernet) Motion Control (Drives, Motors, Servo Systems) Manufacturing Execution Systems (MES) & Industrial Software |

| By End-User | Automotive & EV Food & Beverage Pharmaceuticals & Biotech Electronics & Semiconductor Oil & Gas Chemicals & Petrochemicals Metals & Mining Energy & Utilities (Power, Renewables) Pulp & Paper Logistics & Warehousing |

| By Component | Hardware (Controllers, Robots, Drives, Field Devices) Software (SCADA, HMI, MES, Analytics, Digital Twin) Services (Integration, Maintenance, Consulting) |

| By Application | Process Automation Discrete Automation Hybrid Automation Industrial Safety & Cybersecurity |

| By Sales Channel | Direct Sales Value-Added Resellers & System Integrators Online & E-commerce |

| By Distribution Mode | OEM Distribution Authorized Distributors/Wholesale Aftermarket/Spare Parts |

| By Price Range | Entry-Level Mid-Range Premium/High-Performance |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Automotive Manufacturing Automation | 120 | Production Managers, Automation Engineers |

| Pharmaceuticals Industrial Controls | 90 | Quality Assurance Managers, Process Engineers |

| Food Processing Automation | 80 | Operations Directors, Safety Compliance Officers |

| Logistics and Supply Chain Automation | 100 | Supply Chain Managers, IT Directors |

| Energy Sector Automation Solutions | 70 | Energy Managers, Control Systems Analysts |

The Europe Factory Automation and Industrial Controls Market is valued at approximately USD 68 billion, reflecting a strong demand for automation technologies across various manufacturing and process industries, driven by the need for enhanced productivity and competitiveness.