Region:Global

Author(s):Geetanshi

Product Code:KRAA1178

Pages:97

Published On:August 2025

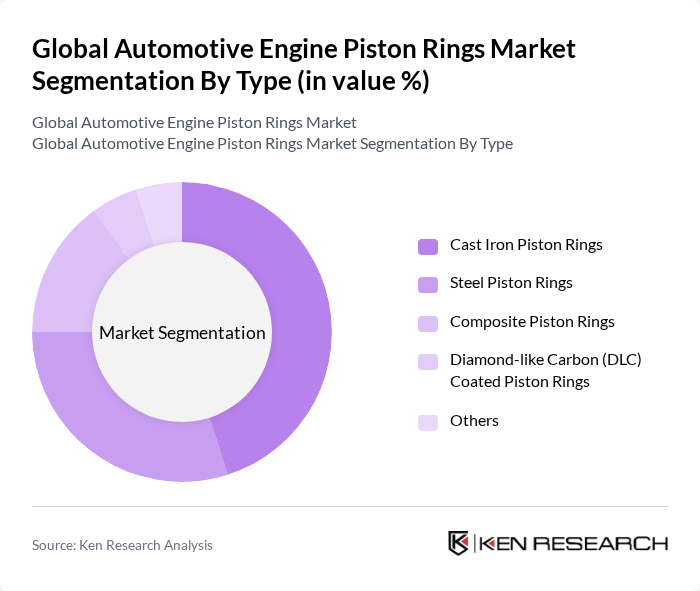

By Type:The market is segmented into Cast Iron Piston Rings, Steel Piston Rings, Composite Piston Rings, Diamond-like Carbon (DLC) Coated Piston Rings, and Others. Cast Iron Piston Rings continue to hold the largest market share due to their cost-effectiveness and durability, making them a preferred choice for many automotive manufacturers. Steel Piston Rings are gaining traction owing to their superior strength and performance, especially in high-performance and heavy-duty engines. Composite and DLC-coated piston rings are increasingly adopted for their enhanced wear resistance and friction reduction, supporting compliance with stricter emission standards and improved engine efficiency .

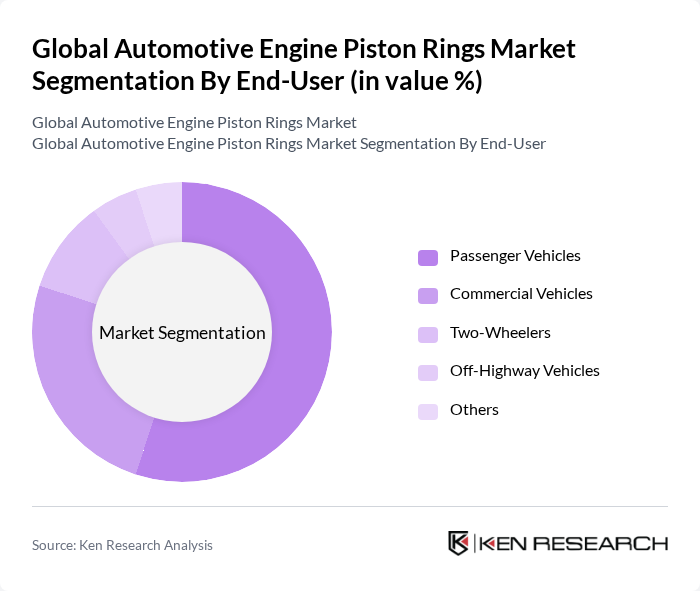

By End-User:The end-user segmentation includes Passenger Vehicles, Commercial Vehicles, Two-Wheelers, Off-Highway Vehicles, and Others. The Passenger Vehicles segment holds the largest share, supported by the growing demand for personal transportation and sustained growth in the global automotive market. Commercial Vehicles remain significant due to the expansion of logistics and transportation sectors, which require durable and efficient engine components. The aftermarket segment is also expanding, driven by increased vehicle ownership and demand for repair and maintenance services .

The Global Automotive Engine Piston Rings Market is characterized by a dynamic mix of regional and international players. Leading participants such as MAHLE GmbH, Federal-Mogul Corporation (Tenneco Inc.), NPR Group (Nippon Piston Ring Co., Ltd.), Sealed Power (SPX Corporation), Aisin Seiki Co., Ltd., Tenneco Inc., Hitachi Astemo, Ltd., RIKEN CORPORATION, Melling Engine Parts, Dart Machinery, Shriram Pistons & Rings Ltd., BorgWarner Inc., ZF Friedrichshafen AG, Continental AG, SKF Group, IP Rings Ltd., Samkrg Pistons & Rings Ltd., Omega Pistons Ltd., Hunan ZhengYuanDongli Parts Co., Ltd., Anhui Huan Xin Group Co., Ltd. contribute to innovation, geographic expansion, and service delivery in this space.

The future of the automotive engine piston rings market appears promising, driven by ongoing technological advancements and a shift towards sustainability. As manufacturers increasingly adopt lightweight materials and eco-friendly designs, the demand for innovative piston ring solutions is expected to rise. Additionally, the growing trend of electric vehicles will likely create new opportunities for piston ring manufacturers to develop specialized products that cater to evolving engine technologies, ensuring a competitive edge in the market.

| Segment | Sub-Segments |

|---|---|

| By Type | Cast Iron Piston Rings Steel Piston Rings Composite Piston Rings Diamond-like Carbon (DLC) Coated Piston Rings Others |

| By End-User | Passenger Vehicles Commercial Vehicles Two-Wheelers Off-Highway Vehicles Others |

| By Engine Type | Gasoline Engines Diesel Engines Hybrid Engines CNG/LPG Engines Others |

| By Sales Channel | OEMs Aftermarket Online Sales Others |

| By Distribution Mode | Direct Sales Distributors Retail Outlets Others |

| By Price Range | Economy Mid-range Premium Others |

| By Application | Engine Performance Enhancement Emission Control Durability Improvement Fuel Efficiency Optimization Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| OEM Piston Ring Manufacturers | 60 | Production Managers, R&D Engineers |

| Aftermarket Suppliers | 50 | Sales Directors, Product Line Managers |

| Automotive Industry Analysts | 40 | Market Analysts, Industry Consultants |

| Automotive Component Distributors | 45 | Supply Chain Managers, Procurement Specialists |

| Vehicle Manufacturers | 55 | Quality Assurance Managers, Engineering Leads |

The Global Automotive Engine Piston Rings Market is valued at approximately USD 2.8 billion, driven by the increasing demand for fuel-efficient engines and advanced engine technologies, alongside stringent emission regulations that necessitate high-quality piston rings.