Region:Global

Author(s):Geetanshi

Product Code:KRAD0081

Pages:86

Published On:August 2025

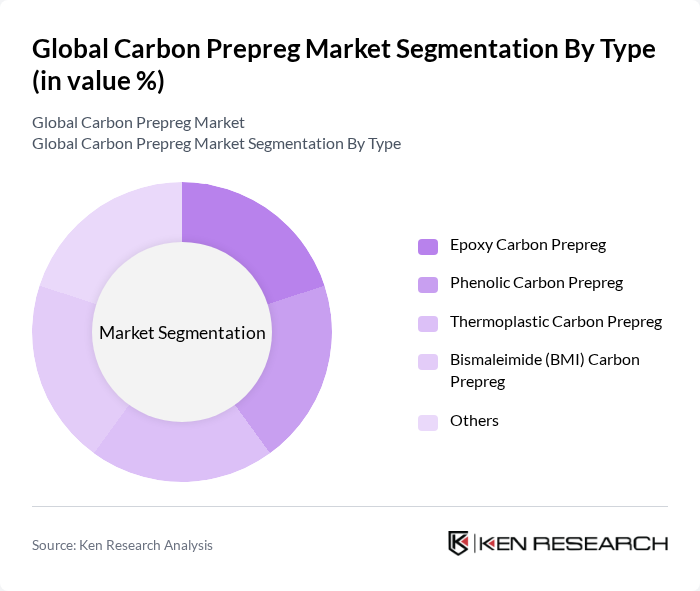

By Type:The carbon prepreg market can be segmented into various types, including Epoxy Carbon Prepreg, Phenolic Carbon Prepreg, Thermoplastic Carbon Prepreg, Bismaleimide (BMI) Carbon Prepreg, and Others. Each type serves different applications and industries, with specific properties that cater to unique requirements .

The Epoxy Carbon Prepreg segment is currently dominating the market due to its excellent mechanical properties, thermal stability, and versatility in various applications. It is widely used in aerospace and automotive industries, where lightweight and high-strength materials are crucial. The increasing demand for fuel-efficient vehicles and advanced aerospace components has further propelled the growth of this segment. Additionally, the ease of processing and cost-effectiveness of epoxy prepregs make them a preferred choice among manufacturers .

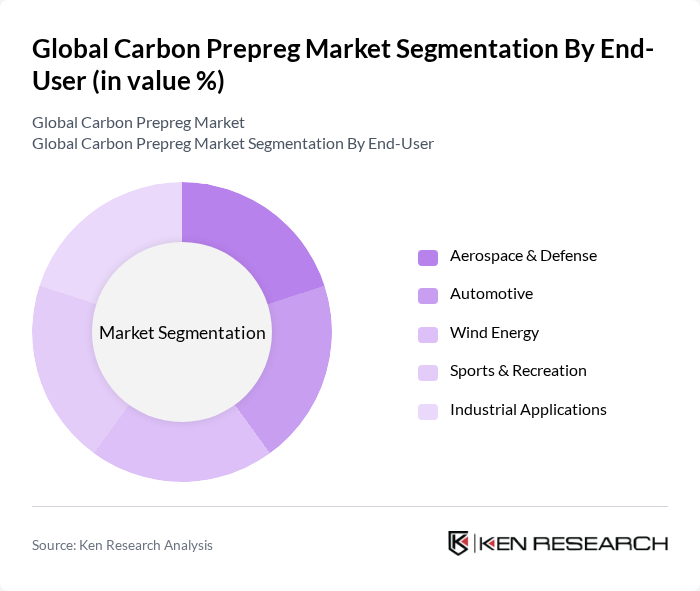

By End-User:The carbon prepreg market is segmented by end-user industries, including Aerospace & Defense, Automotive, Wind Energy, Sports & Recreation, Industrial Applications, and Others. Each segment has distinct requirements and growth drivers based on industry trends and technological advancements .

The Aerospace & Defense segment leads the market due to the increasing demand for lightweight materials that enhance fuel efficiency and performance in aircraft. The stringent regulations regarding emissions and the push for sustainable aviation solutions are driving the adoption of carbon prepregs in this sector. Additionally, advancements in aerospace technology and the need for high-performance components further contribute to the growth of this segment .

The Global Carbon Prepreg Market is characterized by a dynamic mix of regional and international players. Leading participants such as Toray Industries, Inc., Hexcel Corporation, SGL Carbon SE, Mitsubishi Chemical Corporation, Teijin Limited, Solvay S.A., Owens Corning, BASF SE, Gurit Holding AG, Zoltek Companies, Inc., Composites One LLC, Axiom Materials, Inc., Formosa Plastics Corporation, Jushi Group Co., Ltd., Park Aerospace Corp., TCR Composites, Inc., SHD Composite Materials Ltd., North Thin Ply Technology (NTPT) contribute to innovation, geographic expansion, and service delivery in this space.

The future of the carbon prepreg market appears promising, driven by technological advancements and a growing emphasis on sustainability. As industries increasingly prioritize lightweight materials to enhance efficiency and reduce emissions, the demand for carbon prepreg is expected to rise. Innovations in manufacturing processes and recycling technologies will likely lower production costs and improve material availability, fostering broader adoption across sectors. Additionally, strategic collaborations between manufacturers and end-users will facilitate the development of new applications, further expanding market potential.

| Segment | Sub-Segments |

|---|---|

| By Type | **Epoxy Carbon Prepreg** **Phenolic Carbon Prepreg** **Thermoplastic Carbon Prepreg** **Bismaleimide (BMI) Carbon Prepreg** Others |

| By End-User | Aerospace & Defense Automotive Wind Energy Sports & Recreation Industrial Applications Others |

| By Application | Structural Components Interior Components Exterior Components Wind Turbine Blades Sporting Goods Others |

| By Manufacturing Process | Prepreg Layup Resin Transfer Molding (RTM) Autoclave Process Vacuum Infusion Others |

| By Distribution Channel | Direct Sales Distributors Online Sales Others |

| By Region | North America Europe Asia-Pacific Latin America Middle East & Africa |

| By Price Range | Low Price Mid Price High Price Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Aerospace Applications | 100 | Materials Engineers, Aerospace Product Managers |

| Automotive Sector | 80 | Supply Chain Managers, Automotive Engineers |

| Wind Energy Sector | 70 | Project Managers, Renewable Energy Analysts |

| Sports Equipment Manufacturing | 50 | Product Development Managers, Brand Managers |

| Construction Industry | 60 | Construction Managers, Structural Engineers |

The Global Carbon Prepreg Market is valued at approximately USD 9 billion, driven by the increasing demand for lightweight and high-strength materials, particularly in the aerospace and automotive industries, as well as the growing adoption in wind energy applications.