Region:Global

Author(s):Rebecca

Product Code:KRAA2423

Pages:86

Published On:August 2025

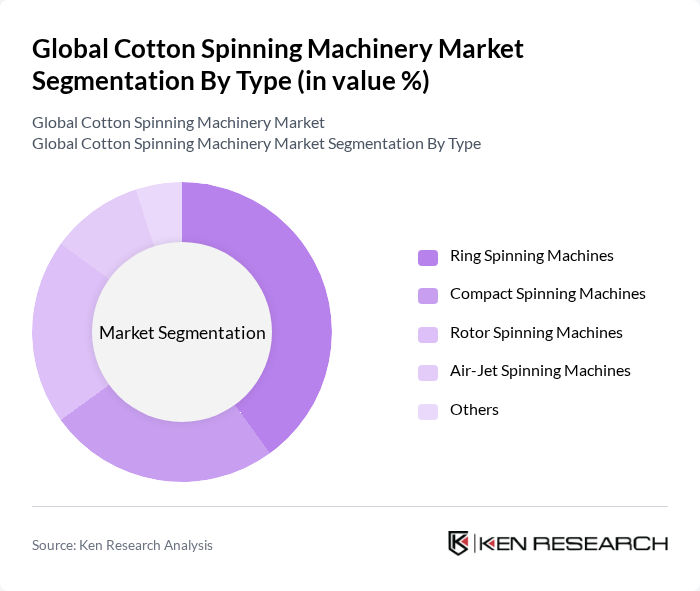

By Type:The cotton spinning machinery market is segmented into various types, including Ring Spinning Machines, Compact Spinning Machines, Rotor Spinning Machines, Air-Jet Spinning Machines, and Others. Among these,Ring Spinning Machinesare the most widely used due to their versatility and ability to produce high-quality yarn.Compact Spinning Machinesare gaining traction for their efficiency and reduced yarn hairiness, whileRotor Spinning Machinesare preferred for their high-speed production capabilities. The demand forAir-Jet Spinning Machinesis also increasing, particularly in the production of specialty yarns.

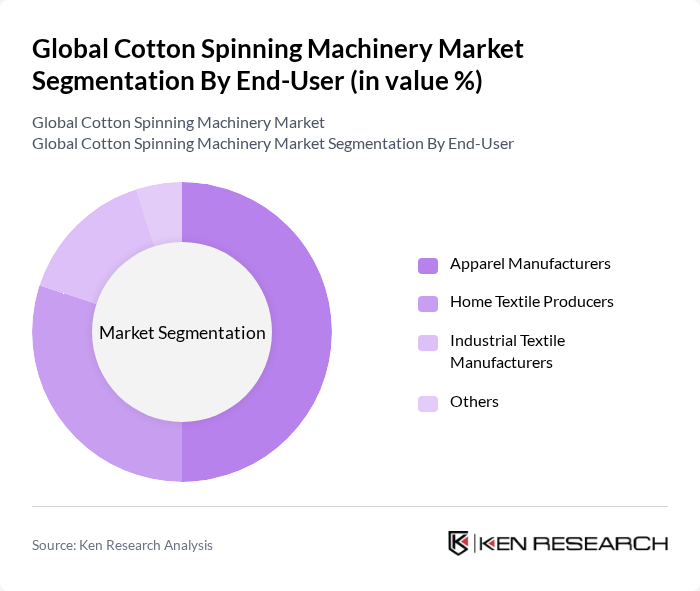

By End-User:The market is also segmented by end-user, which includes Apparel Manufacturers, Home Textile Producers, Industrial Textile Manufacturers, and Others.Apparel Manufacturersdominate the market due to the high demand for cotton garments globally.Home Textile Producersare also significant players, driven by the growing trend of home decor and furnishings.Industrial Textile Manufacturersare increasingly adopting advanced spinning technologies to meet the specific requirements of technical textiles.

The Global Cotton Spinning Machinery Market is characterized by a dynamic mix of regional and international players. Leading participants such as Rieter Holding AG, Trützschler GmbH & Co. KG, Saurer AG, Murata Machinery, Ltd., Toyota Industries Corporation, Lakshmi Machine Works Limited (LMW), Savio Macchine Tessili S.p.A., Jingwei Textile Machinery Co., Ltd., Zhejiang Taitan Co., Ltd., Marzoli Machines Textile S.r.l., SSM Schärer Schweiter Mettler AG, A.T.E. Enterprises Private Limited, Schlafhorst (part of Saurer Group), Qingdao Hongda Textile Machinery Co., Ltd., Bajaj Steel Industries Limited contribute to innovation, geographic expansion, and service delivery in this space.

The future of the cotton spinning machinery market is poised for transformation, driven by technological advancements and a growing emphasis on sustainability. As manufacturers increasingly adopt automation and IoT technologies, operational efficiencies are expected to improve significantly. Additionally, the rising consumer demand for eco-friendly textiles will compel producers to innovate further, ensuring compliance with environmental standards. This dynamic landscape will likely foster collaborations between machinery manufacturers and sustainable brands, enhancing market resilience and adaptability.

| Segment | Sub-Segments |

|---|---|

| By Type | Ring Spinning Machines Compact Spinning Machines Rotor Spinning Machines Air-Jet Spinning Machines Others |

| By End-User | Apparel Manufacturers Home Textile Producers Industrial Textile Manufacturers Others |

| By Application | Yarn Production Fabric Manufacturing Specialty Textiles Others |

| By Distribution Channel | Direct Sales Distributors Online Sales Others |

| By Region | North America Europe Asia-Pacific Latin America Middle East & Africa |

| By Price Range | Low-End Machinery Mid-Range Machinery High-End Machinery |

| By Technology | Automated Spinning Technology Manual Spinning Technology Hybrid Spinning Technology Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Cotton Spinning Mills | 100 | Production Managers, Technical Directors |

| Machinery Manufacturers | 60 | Sales Managers, Product Development Managers |

| Textile Industry Associations | 40 | Policy Makers, Industry Analysts |

| Research Institutions | 40 | Textile Researchers, Academic Professors |

| End-User Textile Companies | 50 | Supply Chain Managers, Quality Control Officers |

The Global Cotton Spinning Machinery Market is valued at approximately USD 5 billion, driven by increasing demand for cotton textiles and advancements in spinning technology. This market has seen significant investments aimed at enhancing production efficiency and reducing operational costs.