Region:Global

Author(s):Dev

Product Code:KRAB0646

Pages:85

Published On:August 2025

Recycling Market.png)

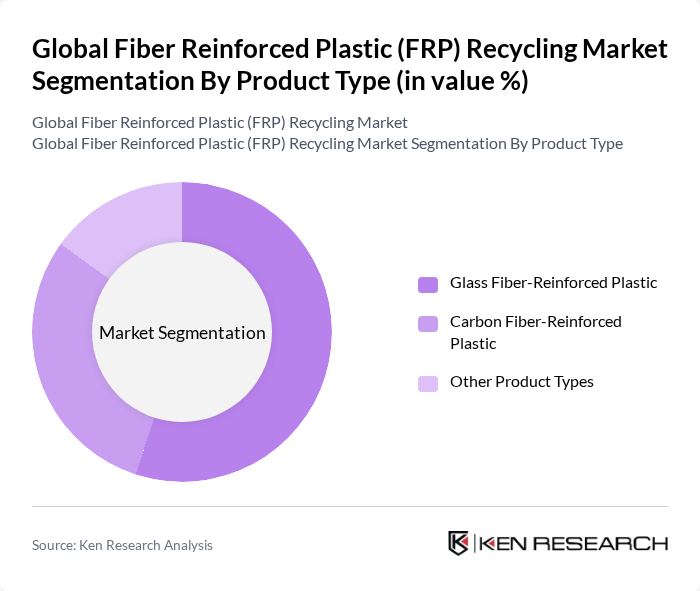

By Product Type:The product type segmentation includes Glass Fiber-Reinforced Plastic, Carbon Fiber-Reinforced Plastic, and Other Product Types. Glass Fiber-Reinforced Plastic dominates due to its extensive use in automotive, construction, wind energy, and marine applications. Its lightweight, corrosion resistance, and cost-effectiveness drive adoption in mass-market sectors. Carbon Fiber-Reinforced Plastic, while more costly, is increasingly adopted in aerospace, high-performance automotive, and sports equipment, where superior strength-to-weight ratios are critical. Other product types include specialty composites used in niche industrial and infrastructure projects .

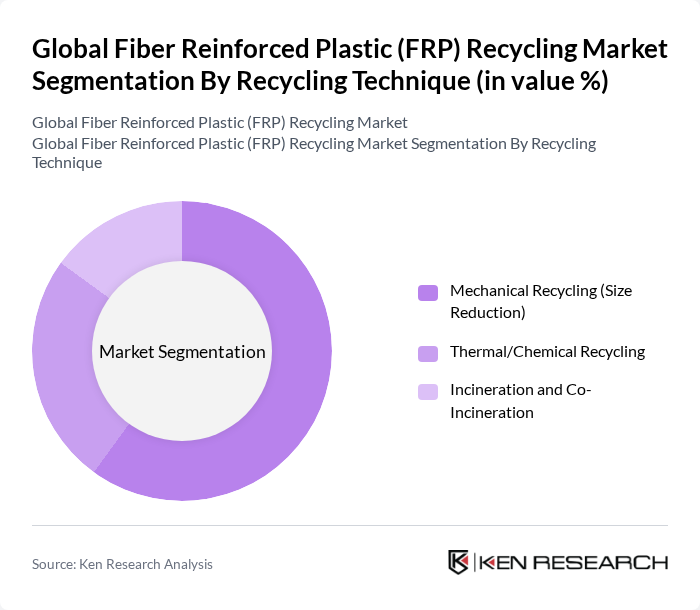

By Recycling Technique:The recycling technique segmentation includes Mechanical Recycling (Size Reduction), Thermal/Chemical Recycling, and Incineration and Co-Incineration. Mechanical recycling is the most prevalent due to its cost-efficiency and suitability for glass fiber composites, enabling recovery for use in construction panels and non-structural automotive parts. Thermal/Chemical recycling, including pyrolysis and solvolysis, is gaining traction for carbon fiber composites and complex waste, offering higher purity fiber recovery. Incineration and co-incineration are primarily used for energy recovery from end-of-life FRP, but face declining preference due to emissions and stricter environmental standards .

The Global Fiber Reinforced Plastic (FRP) Recycling Market is characterized by a dynamic mix of regional and international players. Leading participants such as Veolia Environnement S.A., SUEZ Recycling and Recovery, Covestro AG, BASF SE, DSM N.V., CarbonLite Industries, Reciplast S.A., Ahlstrom-Munksjö, EREMA Engineering Recycling Maschinen und Anlagen Ges.m.b.H., Biffa plc, GFL Environmental Inc., Waste Management, Inc., Clean Harbors, Inc., Advanced Environmental Recycling Technologies, Inc., GreenMantra Technologies, Inc., Unicomposites AS, Carbon Conversions, Inc., Aeron Composites Pvt. Ltd., Conenor Ltd. contribute to innovation, geographic expansion, and service delivery in this space.

The future of the FRP recycling market appears promising, driven by increasing regulatory pressures and a societal shift towards sustainability. As more industries adopt circular economy principles, the demand for recycled FRP is expected to rise significantly. Furthermore, ongoing research and development efforts are likely to yield innovative recycling technologies, enhancing material recovery rates and reducing costs. This evolving landscape will create new opportunities for businesses to capitalize on sustainable practices while meeting regulatory requirements.

| Segment | Sub-Segments |

|---|---|

| By Product Type | Glass Fiber-Reinforced Plastic Carbon Fiber-Reinforced Plastic Other Product Types |

| By Recycling Technique | Mechanical Recycling (Size Reduction) Thermal/Chemical Recycling Incineration and Co-Incineration |

| By End-User Industry | Industrial Transportation Building and Construction Sports Other End-User Industries |

| By Geography | Asia-Pacific North America Europe Rest of the World |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Automotive FRP Recycling | 100 | Production Managers, Sustainability Coordinators |

| Aerospace Composite Waste Management | 60 | Quality Assurance Managers, Environmental Compliance Officers |

| Construction Material Recovery | 55 | Project Managers, Waste Management Specialists |

| Marine Industry Recycling Practices | 40 | Fleet Managers, Environmental Engineers |

| Consumer Goods FRP Applications | 70 | Product Development Managers, Supply Chain Analysts |

The Global Fiber Reinforced Plastic (FRP) Recycling Market is valued at approximately USD 505 million, driven by increasing environmental regulations and the demand for sustainable materials across various sectors, including automotive, construction, and marine.