Region:Global

Author(s):Dev

Product Code:KRAB0639

Pages:94

Published On:August 2025

By Technology:The technology segment includes various methods used in food 3D printing, such as extrusion-based printing, binder jetting, selective laser sintering (SLS), inkjet printing, and others. Among these, extrusion-based printing is the most widely adopted due to its versatility and ability to process a broad range of food materials. The demand for customized food products and the technology’s suitability for commercial kitchens and bakeries have led to increased investments in extrusion-based systems, making it the leading technology in the market .

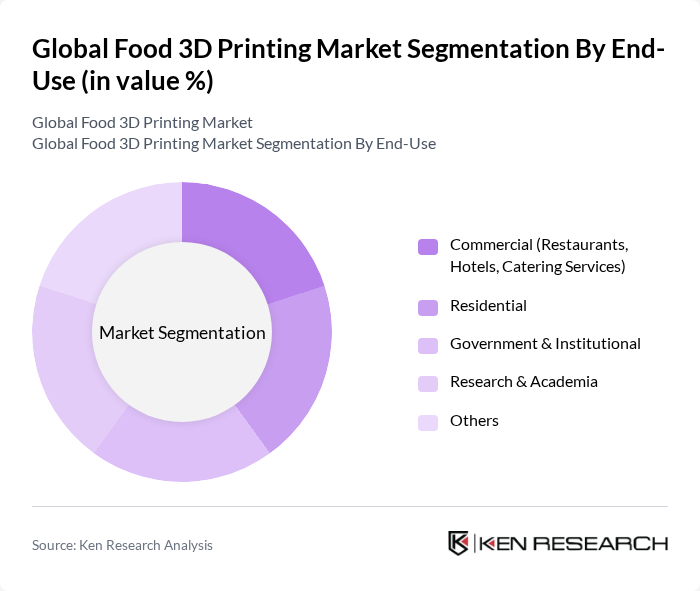

By End-Use:The end-use segment covers commercial (restaurants, hotels, catering services), residential, government & institutional, research & academia, and others. The commercial segment is the largest, driven by the hospitality industry’s adoption of 3D printing for personalized dining experiences, innovative food presentation, and menu differentiation. Restaurants and catering services are increasingly utilizing 3D food printers to create intricate, customized dishes that enhance customer engagement and brand identity .

The Global Food 3D Printing Market is characterized by a dynamic mix of regional and international players. Leading participants such as 3D Systems Corporation, Natural Machines (Foodini), BeeHex, Print2Taste (mycusini), Redefine Meat, TNO (Netherlands Organisation for Applied Scientific Research), ByFlow, Barilla Group, SavorEat, Novameat, Choc Edge, Brill Inc. (a CSM Bakery Solutions company), Nestlé, Unilever, Cargill contribute to innovation, geographic expansion, and service delivery in this space.

The future of the food 3D printing market appears promising, driven by technological advancements and evolving consumer preferences. As the market matures, we can expect increased collaboration between food technologists and culinary experts, leading to innovative product offerings. Additionally, the integration of artificial intelligence in food design and production processes will enhance customization and efficiency. These trends will likely foster a more dynamic market environment, encouraging further investment and development in the sector.

| Segment | Sub-Segments |

|---|---|

| By Technology | Extrusion-Based Printing Binder Jetting Selective Laser Sintering (SLS) Inkjet Printing Others |

| By End-Use | Commercial (Restaurants, Hotels, Catering Services) Residential Government & Institutional Research & Academia Others |

| By Application | Customized Food Products Prototyping and R&D Food Decoration Nutritional Customization Others |

| By Ingredient/Material Type | Chocolate & Confectionery Dough & Bakery Dairy Products Fruits & Vegetables Meat & Alternative Proteins Others |

| By Component | Hardware Software Services |

| By Distribution Channel | Direct Sales Online Retail Distributors Trade Shows Others |

| By Region | North America Europe Asia-Pacific Latin America Middle East & Africa |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Restaurant Industry Adoption | 100 | Restaurant Owners, Executive Chefs |

| Home Kitchen Users | 60 | Home Cooks, Culinary Enthusiasts |

| Food Manufacturing Sector | 50 | Production Managers, R&D Specialists |

| Consumer Acceptance Studies | 90 | General Consumers, Health-Conscious Individuals |

| Food Technology Experts | 40 | Food Scientists, Technology Innovators |

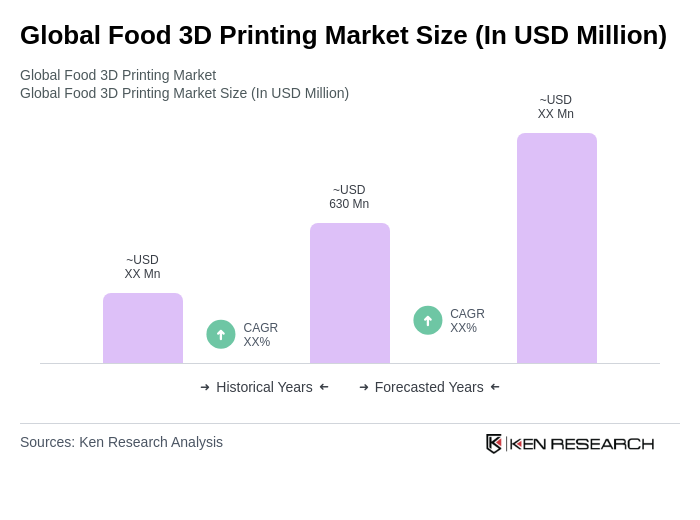

The Global Food 3D Printing Market is valued at approximately USD 630 million, driven by advancements in technology, consumer demand for personalized nutrition, and sustainable food production methods.