Region:Global

Author(s):Geetanshi

Product Code:KRAA1219

Pages:82

Published On:August 2025

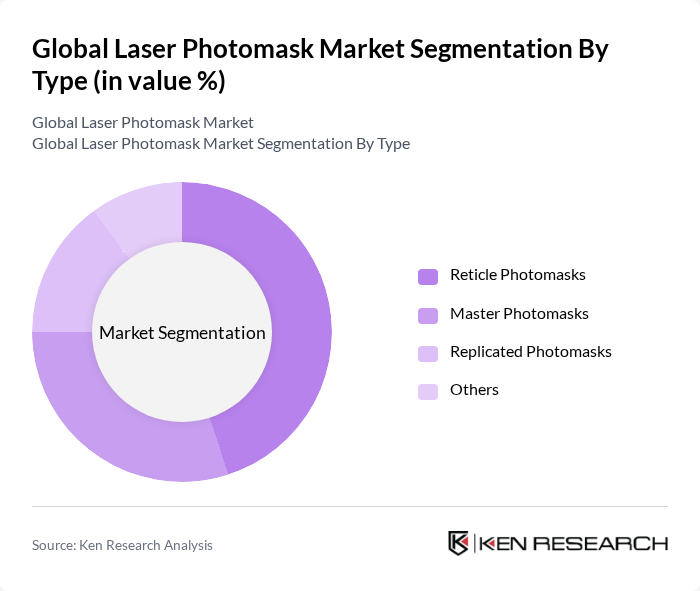

By Type:The market is segmented into four main types: Reticle Photomasks, Master Photomasks, Replicated Photomasks, and Others. Among these, Reticle Photomasks are the most dominant due to their essential role in the photolithography process for semiconductor manufacturing. The increasing complexity of integrated circuits and the demand for higher resolution and miniaturization in electronic devices have led to a surge in the adoption of Reticle Photomasks. Master Photomasks also hold a significant share, as they are critical for producing multiple copies of photomasks used in various applications .

By Trade Type:The market is divided into Captive and Merchant trade types. Captive photomasks are primarily used by semiconductor manufacturers for in-house production, while Merchant photomasks are sold to various end-users. The Captive segment is leading due to the increasing trend of vertical integration among semiconductor companies, allowing them to maintain control over their production processes and ensure quality. Merchant photomasks are also gaining traction as more companies seek specialized photomask solutions from external suppliers .

The Global Laser Photomask Market is characterized by a dynamic mix of regional and international players. Leading participants such as Photronics, Inc., Toppan Photomasks, Inc., Dai Nippon Printing Co., Ltd. (DNP), Hoya Corporation, Taiwan Mask Corporation, Compugraphics International Ltd., SK-Electronics Co., Ltd., Advanced Reproductions Corporation, LG Innotek Co., Ltd., Nippon Filcon Co., Ltd., Applied Materials, Inc., KLA Corporation, SÜSS MicroTec SE, EV Group (EVG), Canon Inc. contribute to innovation, geographic expansion, and service delivery in this space.

The future of the laser photomask market appears promising, driven by technological advancements and increasing demand for high-performance semiconductors. As industries continue to adopt AI and IoT technologies, the need for innovative manufacturing processes will grow. Furthermore, the shift towards sustainable practices in semiconductor production will likely lead to the development of eco-friendly photomasks, enhancing market competitiveness and addressing environmental concerns.

| Segment | Sub-Segments |

|---|---|

| By Type | Reticle Photomasks Master Photomasks Replicated Photomasks Others |

| By Trade Type | Captive Merchant |

| By End-User | Semiconductor Manufacturers Electronics Manufacturers Research Institutions Others |

| By Application | Integrated Circuits MEMS Devices LED Manufacturing High-Resolution Displays Others |

| By Region | Asia-Pacific North America Europe Rest of World |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Semiconductor Manufacturing | 100 | Production Managers, Process Engineers |

| Photomask Production | 60 | Quality Control Analysts, Operations Managers |

| Research & Development in Photomask Technology | 50 | R&D Directors, Technology Specialists |

| End-user Applications in Electronics | 40 | Product Managers, Application Engineers |

| Market Analysts and Consultants | 40 | Market Research Analysts, Industry Consultants |

The Global Laser Photomask Market is valued at approximately USD 5 billion, driven by the increasing demand for high-performance semiconductor devices and advanced photomask technologies essential for manufacturing.