Region:Global

Author(s):Dev

Product Code:KRAC0405

Pages:90

Published On:August 2025

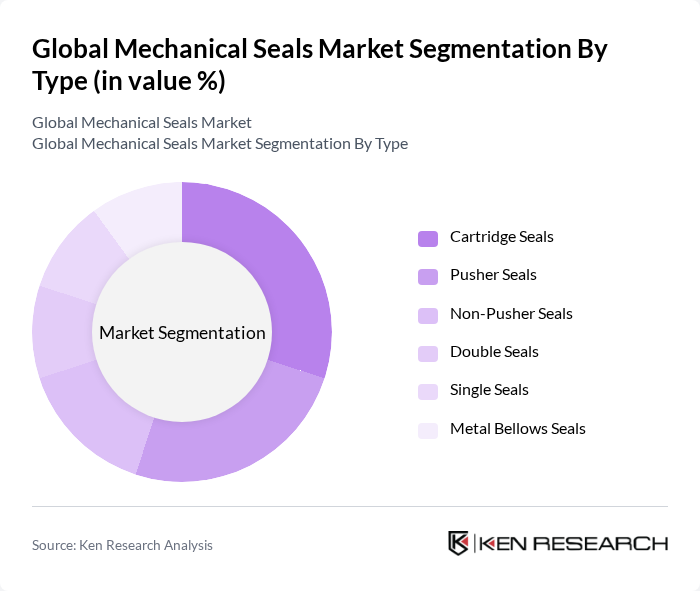

By Type:The mechanical seals market can be segmented into various types, includingCartridge Seals,Pusher Seals,Non-Pusher Seals,Double Seals,Single Seals, andMetal Bellows Seals. Cartridge seals are widely adopted due to **ease of installation, reduced installation error risk, and maintenance efficiency**, which lowers downtime and total cost of ownership for end users.

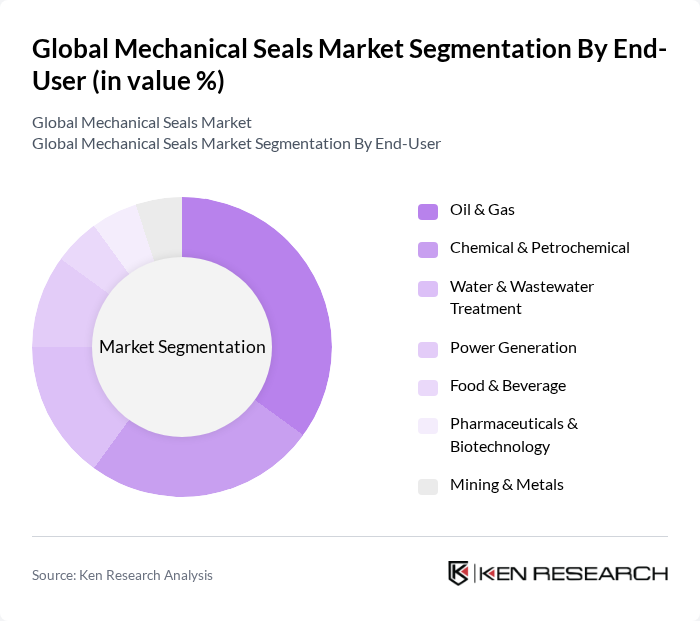

By End-User:End-user industries includeOil & Gas,Chemical & Petrochemical,Water & Wastewater Treatment,Power Generation,Food & Beverage,Pharmaceuticals & Biotechnology, andMining & Metals. Oil & Gas, chemicals, and water industries are core demand centers due to stringent leakage control, emissions reduction, and reliability requirements in pumps, compressors, and agitators operating under high temperatures, pressures, and corrosive media.

The Global Mechanical Seals Market is characterized by a dynamic mix of regional and international players. Leading participants such as John Crane (Smiths Group plc), Flowserve Corporation, EagleBurgmann (Freudenberg & EKK), A.W. Chesterton Company, AESSEAL plc, Flexaseal Engineered Seals & Systems LLC, Sulzer Ltd., KSB SE & Co. KGaA, Meccanotecnica Umbra S.p.A., Technetics Group (EnPro Industries), Trelleborg Sealing Solutions, SKF Group, Hallite Seals International, Dichtomatik GmbH (Freudenberg Sealing Technologies), Sinoseal Holding Co., Ltd., Freudenberg Sealing Technologies, Parker Hannifin (Engineered Materials Group), James Walker Group Ltd., Omniseal Solutions (Saint-Gobain), UTEX Industries, Inc. contribute to innovation, geographic expansion, and service delivery in this space.

The future of the mechanical seals market appears promising, driven by ongoing technological advancements and increasing industrial automation. As industries strive for enhanced efficiency and sustainability, the demand for high-performance seals is expected to rise. Furthermore, the integration of IoT technologies will facilitate predictive maintenance, reducing downtime and operational costs. Companies that adapt to these trends will likely capture significant market share, positioning themselves favorably in a competitive landscape.

| Segment | Sub-Segments |

|---|---|

| By Type | Cartridge Seals Pusher Seals Non-Pusher Seals Double Seals Single Seals Metal Bellows Seals |

| By End-User | Oil & Gas Chemical & Petrochemical Water & Wastewater Treatment Power Generation Food & Beverage Pharmaceuticals & Biotechnology Mining & Metals |

| By Application | Pumps Compressors Mixers Agitators Reactors & Turbines |

| By Material | Metals & Alloys Elastomers Ceramics (e.g., Silicon Carbide) Carbon/Graphite Tungsten Carbide |

| By Distribution Channel | Direct OEM Sales Authorized Distributors Online Sales MRO/Aftermarket Services |

| By Region | North America Europe Asia-Pacific Latin America Middle East & Africa |

| By Price Range | Low Medium High |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Oil & Gas Industry | 120 | Maintenance Managers, Operations Engineers |

| Chemical Processing Sector | 90 | Procurement Managers, Process Engineers |

| Water Treatment Facilities | 60 | Plant Managers, Environmental Engineers |

| Food & Beverage Industry | 50 | Quality Assurance Managers, Production Supervisors |

| Pharmaceutical Manufacturing | 80 | Regulatory Affairs Specialists, Production Managers |

The Global Mechanical Seals Market is valued at approximately USD 4.3 billion, based on a comprehensive five-year analysis. This valuation reflects the market's growth and demand across various industries, particularly in North America, Europe, and Asia-Pacific.