Region:Global

Author(s):Dev

Product Code:KRAA1497

Pages:97

Published On:August 2025

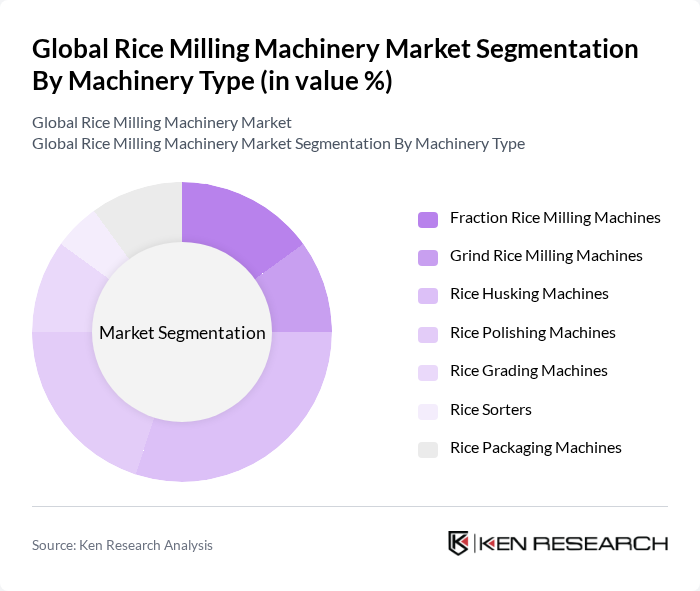

By Machinery Type:The machinery type segment includes various types of equipment used in rice milling processes. The subsegments are Fraction Rice Milling Machines, Grind Rice Milling Machines, Rice Husking Machines, Rice Polishing Machines, Rice Grading Machines, Rice Sorters, and Rice Packaging Machines. Among these, Rice Husking Machines are widely adopted due to their essential role in the initial stages of rice processing, where the outer husk is removed to produce brown rice. The increasing demand for high-quality rice and the need for efficient processing methods are driving the adoption of these machines .

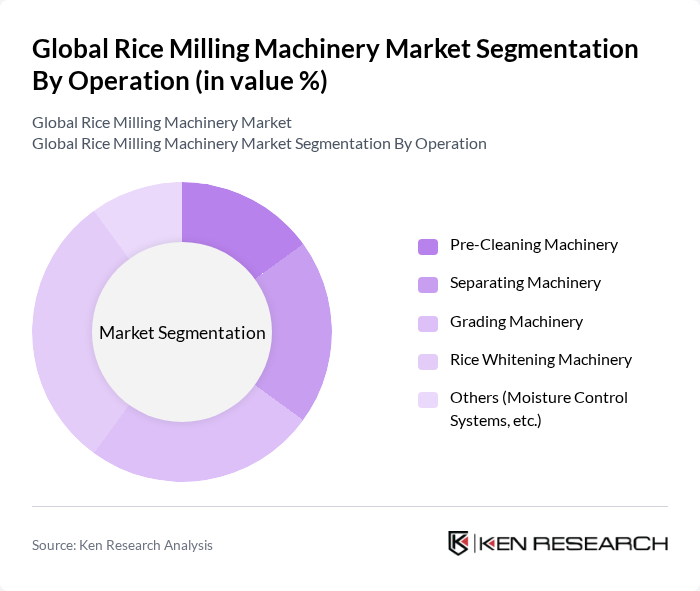

By Operation:The operation segment encompasses various processes involved in rice milling. This includes Pre-Cleaning Machinery, Separating Machinery, Grading Machinery, Rice Whitening Machinery, and Others (Moisture Control Systems, etc.). Rice Whitening Machinery is prominent in the market, as it is crucial for enhancing the quality and appearance of rice. The growing consumer preference for polished rice and the need for high-quality end products are driving the demand for advanced whitening technologies .

The Global Rice Milling Machinery Market is characterized by a dynamic mix of regional and international players. Leading participants such as Satake Corporation, Bühler AG, GEA Group AG, Alvan Blanch Development Company Ltd., Lianyungang Huasheng Machinery Co., Ltd., Akyurek Technology, Agrosaw, Milltec Machinery Pvt. Ltd., Hubei Yongxiang Food Processing Machinery Co., Ltd., Zhengzhou VOS Machinery Equipment Co., Ltd., Perfect Equipments, Ricetec Machinery Pvt. Ltd., Yanagihara Milling Machine Co., Ltd., Anzai Manufacturing Co., Ltd., Wuhan Anon Tech-Trade Co., Ltd. contribute to innovation, geographic expansion, and service delivery in this space .

The future of the rice milling machinery market appears promising, driven by ongoing technological advancements and increasing global rice consumption. As automation and IoT technologies become more prevalent, efficiency and productivity in milling processes are expected to improve significantly. Additionally, sustainability initiatives will likely shape the market, with a focus on eco-friendly practices and energy-efficient machinery, aligning with global trends toward environmental responsibility and resource conservation.

| Segment | Sub-Segments |

|---|---|

| By Machinery Type | Fraction Rice Milling Machines Grind Rice Milling Machines Rice Husking Machines Rice Polishing Machines Rice Grading Machines Rice Sorters Rice Packaging Machines |

| By Operation | Pre-Cleaning Machinery Separating Machinery Grading Machinery Rice Whitening Machinery Others (Moisture Control Systems, etc.) |

| By End-Use | Commercial Milling Industrial Milling Community/Cooperative Milling |

| By Distribution Channel | Direct Sales Distributors Online Sales Others |

| By Region | Asia-Pacific North America Europe South America Middle East & Africa |

| By Price Range | Low-End Machines Mid-Range Machines High-End Machines |

| By Technology | Conventional Milling Technology Advanced Milling Technology Hybrid Milling Technology Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Rice Milling Equipment Manufacturers | 60 | Product Managers, R&D Directors |

| Rice Mill Operators | 90 | Operations Managers, Plant Supervisors |

| Agricultural Equipment Distributors | 50 | Sales Managers, Distribution Coordinators |

| Government Agricultural Officials | 40 | Policy Makers, Agricultural Extension Officers |

| Research Institutions Focused on Agriculture | 40 | Research Analysts, Agricultural Economists |

The Global Rice Milling Machinery Market is valued at approximately USD 840 million, driven by increasing rice demand and advancements in milling technology that enhance efficiency and yield, particularly in Asia and Africa.