Region:Global

Author(s):Geetanshi

Product Code:KRAD0124

Pages:89

Published On:August 2025

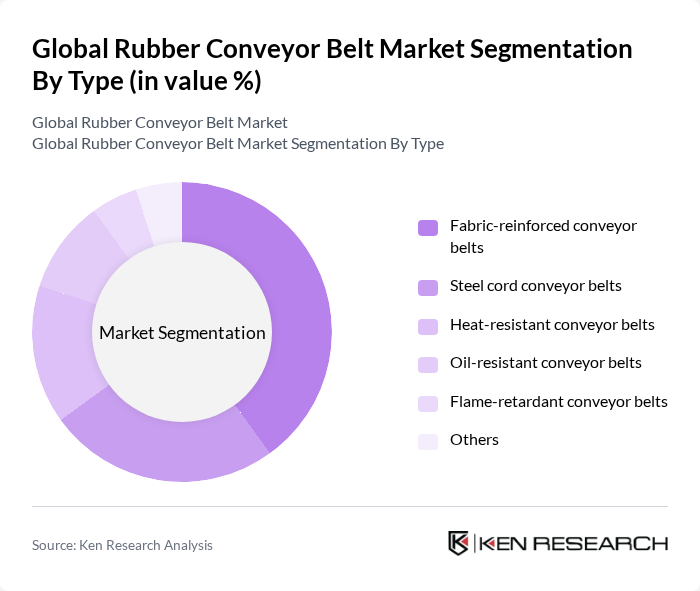

By Type:The market is segmented into various types of conveyor belts, including Fabric-reinforced conveyor belts, Steel cord conveyor belts, Heat-resistant conveyor belts, Oil-resistant conveyor belts, Flame-retardant conveyor belts, and Others. Fabric-reinforced conveyor belts remain the most widely used due to their versatility and cost-effectiveness, serving applications from mining to logistics. Steel cord conveyor belts are preferred for heavy-duty applications, valued for their strength and durability. Demand for specialty belts—such as heat-, oil-, and flame-resistant types—continues to grow, particularly in industries requiring enhanced safety and performance .

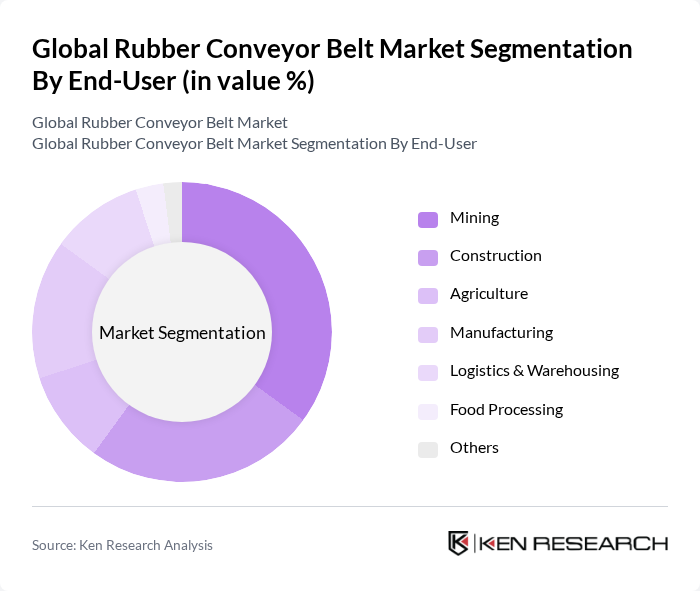

By End-User:The end-user segmentation includes Mining, Construction, Agriculture, Manufacturing, Logistics & Warehousing, Food Processing, and Others. The Mining sector is the largest consumer of rubber conveyor belts, driven by the need for efficient and reliable material transport in mining operations. Construction and Logistics sectors also contribute significantly, with demand supported by infrastructure projects and the expansion of warehousing and distribution networks. Manufacturing and food processing industries are increasingly adopting specialized conveyor solutions to enhance operational efficiency and safety .

The Global Rubber Conveyor Belt Market is characterized by a dynamic mix of regional and international players. Leading participants such as Continental AG, Fenner Dunlop, Bridgestone Corporation, Yokohama Rubber Co., Ltd., Zhejiang Double Arrow Rubber Co., Ltd., Sempertrans Conveyor Belt Solutions GmbH, Bando Chemical Industries, Ltd., Baoding Huayue Rubber Belts Co., Ltd., Smiley Monroe Ltd., Phoenix Conveyor Belt Systems GmbH, Dunlop Conveyor Belting, MLT Minet Lacing Technology, Trelleborg AB, Forbo Siegling GmbH, and Ammeraal Beltech Holding B.V. contribute to innovation, geographic expansion, and service delivery in this space.

The future of the rubber conveyor belt market appears promising, driven by ongoing technological advancements and a growing emphasis on sustainability. As industries increasingly adopt automation and smart technologies, the demand for innovative conveyor solutions is expected to rise. Additionally, the focus on eco-friendly materials and practices will likely shape product development, leading to a more sustainable market landscape. Companies that adapt to these trends will be well-positioned for growth in the coming years.

| Segment | Sub-Segments |

|---|---|

| By Type | Fabric-reinforced conveyor belts Steel cord conveyor belts Heat-resistant conveyor belts Oil-resistant conveyor belts Flame-retardant conveyor belts Others |

| By End-User | Mining Construction Agriculture Manufacturing Logistics & Warehousing Food Processing Others |

| By Application | Bulk material handling Package handling Food processing Recycling & Waste Management Others |

| By Distribution Channel | Direct sales Distributors Online sales Others |

| By Material | Natural rubber Synthetic rubber (SBR, NBR, EPDM, etc.) Others |

| By Region | North America Europe Asia-Pacific Latin America Middle East & Africa |

| By Price Range | Low price Mid-range Premium Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Mining Industry Conveyor Belt Usage | 100 | Operations Managers, Equipment Maintenance Supervisors |

| Food Processing Sector Applications | 60 | Production Managers, Quality Assurance Leads |

| Logistics and Warehousing Solutions | 70 | Supply Chain Managers, Warehouse Operations Heads |

| Manufacturing Sector Insights | 50 | Plant Managers, Procurement Specialists |

| Construction and Heavy Equipment | 40 | Project Managers, Equipment Operators |

The Global Rubber Conveyor Belt Market is valued at approximately USD 4.3 billion, driven by increasing demand for efficient bulk material handling across various industries, including mining, cement, and power generation.