Region:Global

Author(s):Rebecca

Product Code:KRAD8455

Pages:98

Published On:December 2025

Market.png)

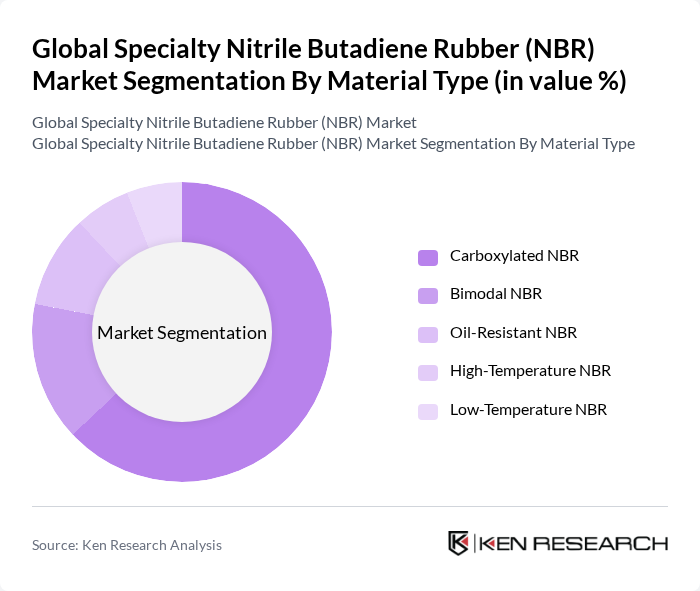

By Material Type:The material type segmentation of the NBR market includes Carboxylated NBR, Bimodal NBR, Oil-Resistant NBR, High-Temperature NBR, and Low-Temperature NBR. Among these, Carboxylated NBR is the leading subsegment due to its superior abrasion resistance, tensile strength, and oil resistance, making it highly suitable for automotive, oil and gas, and manufacturing applications. The growing automotive sector, particularly in regions like North America and Asia-Pacific, has significantly contributed to the demand for Carboxylated NBR. Additionally, the increasing focus on high-performance materials in various industries has further propelled the growth of this subsegment.

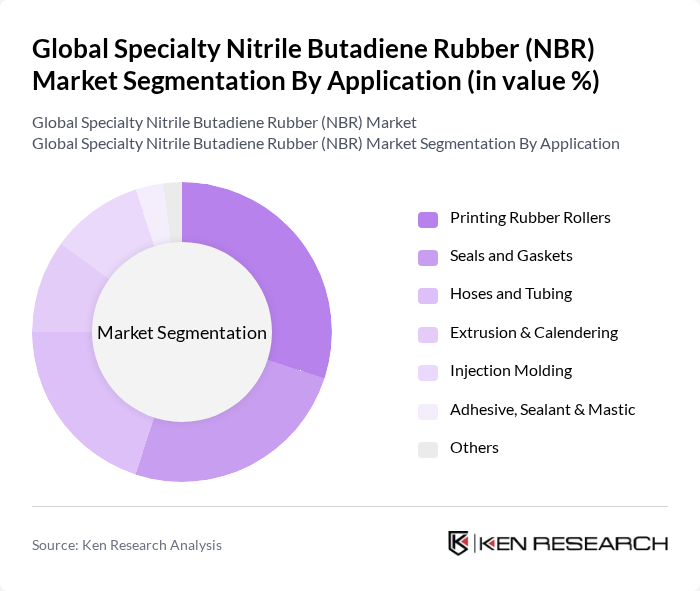

By Application:The application segmentation of the NBR market includes Printing Rubber Rollers, Seals and Gaskets, Hoses and Tubing, Extrusion & Calendering, Injection Molding, Adhesive, Sealant & Mastic, and Others. The Printing Rubber Rollers subsegment is currently dominating the market due to the excellent resistance of NBR to oils, chemicals, and abrasion, which ensures durability in demanding printing processes. The need for reliable materials that can withstand harsh environments and chemicals has led to a surge in the use of NBR-based printing rollers, particularly in industrial sectors.

The Global Specialty Nitrile Butadiene Rubber (NBR) Market is characterized by a dynamic mix of regional and international players. Leading participants such as ZEON Corporation, JSR Corporation, China Petrochemical Corporation (Sinopec), American Rubber Products, Lanxess AG, Kumho Petrochemical Co., Ltd., Asahi Kasei Corporation, LG Chem Ltd., Synthos S.A., TSRC Corporation, Kraton Corporation, Dow Chemical Company, ExxonMobil Chemical Company, Bridgestone Corporation, Continental AG contribute to innovation, geographic expansion, and service delivery in this space.

The future of the NBR market appears promising, driven by technological advancements and a growing emphasis on sustainability. As manufacturers invest in eco-friendly production methods, the demand for innovative NBR formulations is expected to rise. Additionally, the expansion of the automotive and medical sectors will likely create new applications for NBR, enhancing its market presence. Strategic collaborations among industry players will further facilitate growth and innovation, positioning NBR as a vital material in various industries.

| Segment | Sub-Segments |

|---|---|

| By Material Type | Carboxylated NBR Bimodal NBR Oil-Resistant NBR High-Temperature NBR Low-Temperature NBR |

| By Application | Printing Rubber Rollers Seals and Gaskets Hoses and Tubing Extrusion & Calendering Injection Molding Adhesive, Sealant & Mastic Others |

| By End-User Industry | Automotive Aerospace Oil and Gas Healthcare Construction Consumer Goods Others |

| By Processing Method | Extrusion Injection Molding Compression Molding Calendering Others |

| By Region | North America Europe Asia-Pacific Latin America Middle East & Africa |

| By Product Form | Sheets Rolls Blocks Others |

| By Market Channel | Direct Sales Distributors Online Sales Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Automotive Applications | 120 | Product Engineers, Procurement Managers |

| Medical Device Manufacturing | 100 | Quality Assurance Managers, R&D Directors |

| Industrial Rubber Products | 80 | Operations Managers, Supply Chain Analysts |

| Consumer Goods Sector | 70 | Marketing Managers, Product Development Leads |

| Research & Development Insights | 60 | Technical Directors, Innovation Managers |

The Global Specialty Nitrile Butadiene Rubber (NBR) Market is valued at approximately USD 720 million, reflecting a robust growth trajectory driven by increasing demand across automotive, healthcare, and oil and gas industries.