Region:Global

Author(s):Rebecca

Product Code:KRAA1345

Pages:82

Published On:August 2025

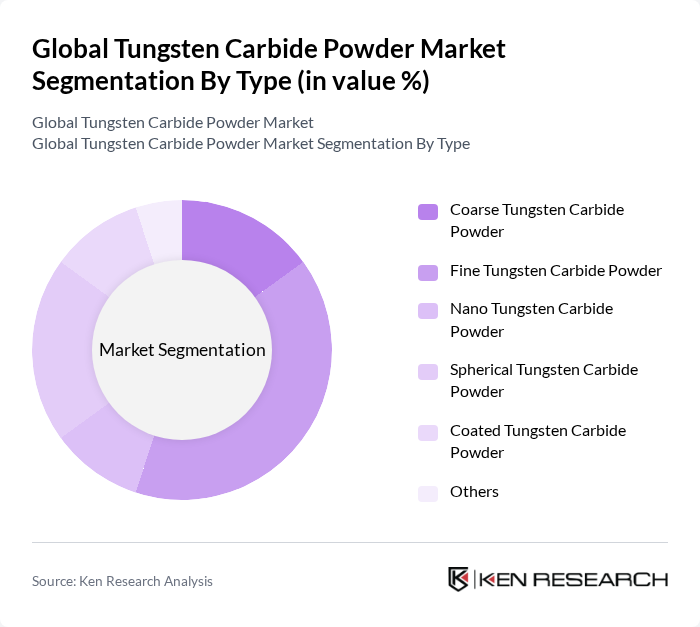

By Type:The tungsten carbide powder market is segmented into various types, including Coarse Tungsten Carbide Powder, Fine Tungsten Carbide Powder, Nano Tungsten Carbide Powder, Spherical Tungsten Carbide Powder, Coated Tungsten Carbide Powder, and Others. Fine Tungsten Carbide Powder holds the largest market share, attributed to its superior hardness and wear resistance, which are essential for precision cutting tools and industrial machinery. The growing adoption of advanced manufacturing technologies and the need for high-performance materials in sectors such as automotive, aerospace, and electronics continue to drive demand for fine powders.

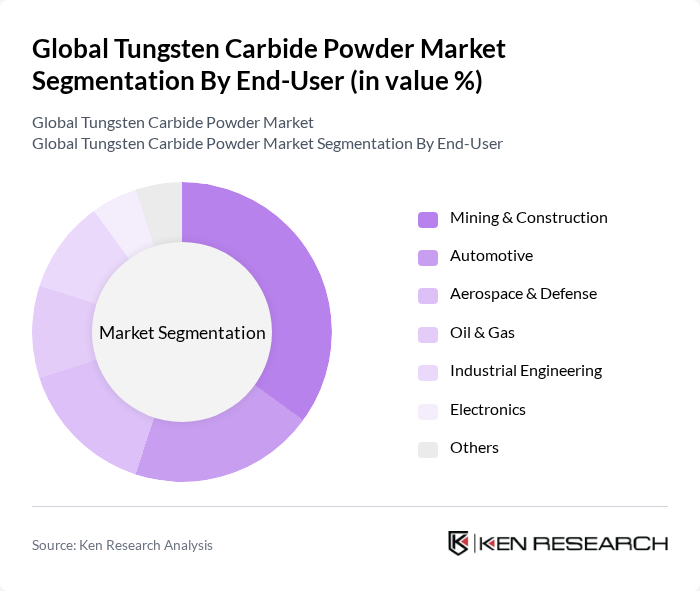

By End-User:The end-user segmentation of the tungsten carbide powder market includes Mining & Construction, Automotive, Aerospace & Defense, Oil & Gas, Industrial Engineering, Electronics, and Others. Mining & Construction is the dominant end-user segment, accounting for the largest share due to the increasing need for durable and efficient tools in drilling, excavation, and infrastructure development. The sector's growth is further supported by rising global investments in infrastructure and energy projects, which require advanced materials for high-performance industrial tools.

The Global Tungsten Carbide Powder Market is characterized by a dynamic mix of regional and international players. Leading participants such as Kennametal Inc., Sandvik AB, Element Six, Mitsubishi Materials Corporation, H.C. Starck GmbH, CERATIZIT S.A., China Tungsten Online (Xiamen) Manu. & Sales Corp., Chongyi ZhangYuan Tungsten Co., Ltd., Federal Carbide Company, Guangdong Xianglu Tungsten Co., Ltd., Japan New Metal Co., Ltd., Nanchang Cemented Carbide Co., Ltd., Reade International Corp., Umicore, Extramet AG contribute to innovation, geographic expansion, and service delivery in this space.

The future of the tungsten carbide powder market appears promising, driven by technological advancements and increasing applications across various sectors. The focus on sustainable manufacturing practices is expected to reshape production processes, leading to more eco-friendly solutions. Additionally, the integration of digital technologies in supply chain management will enhance efficiency and transparency, allowing companies to respond swiftly to market demands and optimize resource allocation, thereby fostering growth in the industry.

| Segment | Sub-Segments |

|---|---|

| By Type | Coarse Tungsten Carbide Powder Fine Tungsten Carbide Powder Nano Tungsten Carbide Powder Spherical Tungsten Carbide Powder Coated Tungsten Carbide Powder Others |

| By End-User | Mining & Construction Automotive Aerospace & Defense Oil & Gas Industrial Engineering Electronics Others |

| By Application | Cutting Tools Wear Parts Dies & Punches Abrasives Drill Bits Nozzles Others |

| By Distribution Channel | Direct Sales Distributors Online Sales Others |

| By Region | North America Europe Asia-Pacific Latin America Middle East & Africa |

| By Price Range | Low Price Range Medium Price Range High Price Range |

| By Packaging Type | Bulk Packaging Small Packaging Customized Packaging Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Mining Industry Applications | 60 | Procurement Managers, Operations Directors |

| Construction Sector Usage | 50 | Project Managers, Materials Engineers |

| Manufacturing and Tooling | 55 | Production Supervisors, Quality Control Managers |

| Aerospace and Defense Applications | 40 | Supply Chain Managers, R&D Engineers |

| Automotive Industry Utilization | 45 | Product Development Managers, Procurement Officers |

The Global Tungsten Carbide Powder Market is valued at approximately USD 15 billion, driven by increasing demand for high-performance materials across various industries such as mining, construction, and manufacturing.