Asia Pacific Glass Fiber Reinforced Concrete Market Outlook to 2030

Region:Asia

Author(s):Meenakshi Bisht

Product Code:KROD8099

December 2024

96

About the Report

Asia Pacific Glass Fiber Reinforced Concrete Market Overview

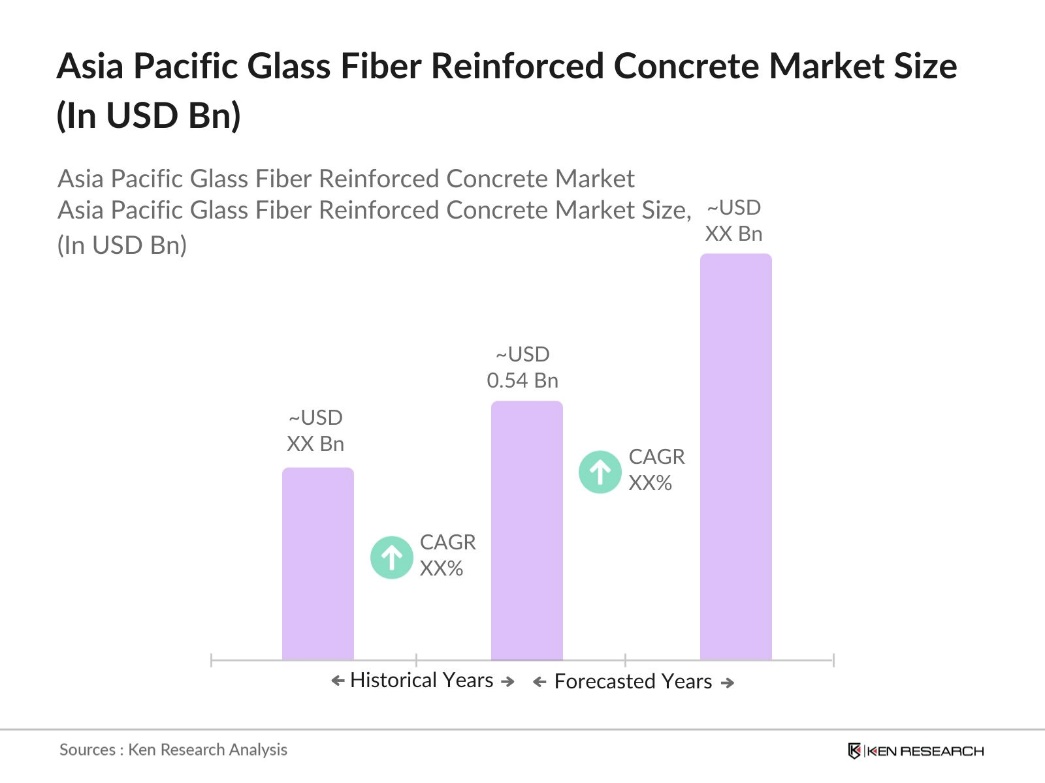

- The Asia Pacific Glass Fiber Reinforced Concrete (GFRC) Market is valued at USD 0.54 billion, based on a five-year historical analysis. The market is driven by increasing infrastructure development and urbanization, with governments across the region focusing on sustainable building materials. The GFRC market benefits from its lightweight and durable nature, which is suited for a variety of construction applications including facades, panels, and decorative elements.

- China, India, and Japan are dominant players in the GFRC market due to their booming construction sectors and government initiatives promoting sustainable building materials. China, for instance, is the largest construction market in the world, with significant infrastructure projects in development. Indias smart city initiatives also drive the demand for innovative materials like GFRC. Japans strict building regulations focusing on earthquake-resistant and eco-friendly materials have led to the increased adoption of GFRC in the country.

- Sustainability certification programs, such as LEED and Green Star, are becoming mandatory for large-scale construction projects in countries like Australia and Singapore. In 2023, Singapore passed a regulation requiring all new government buildings to achieve at least a Green Mark Gold certification, which includes the use of sustainable materials like GFRC. These certifications not only encourage the use of GFRC in large infrastructure projects but also position it as a preferred material for achieving sustainability goals in the construction sector.

Asia Pacific Glass Fiber Reinforced Concrete Market Segmentation

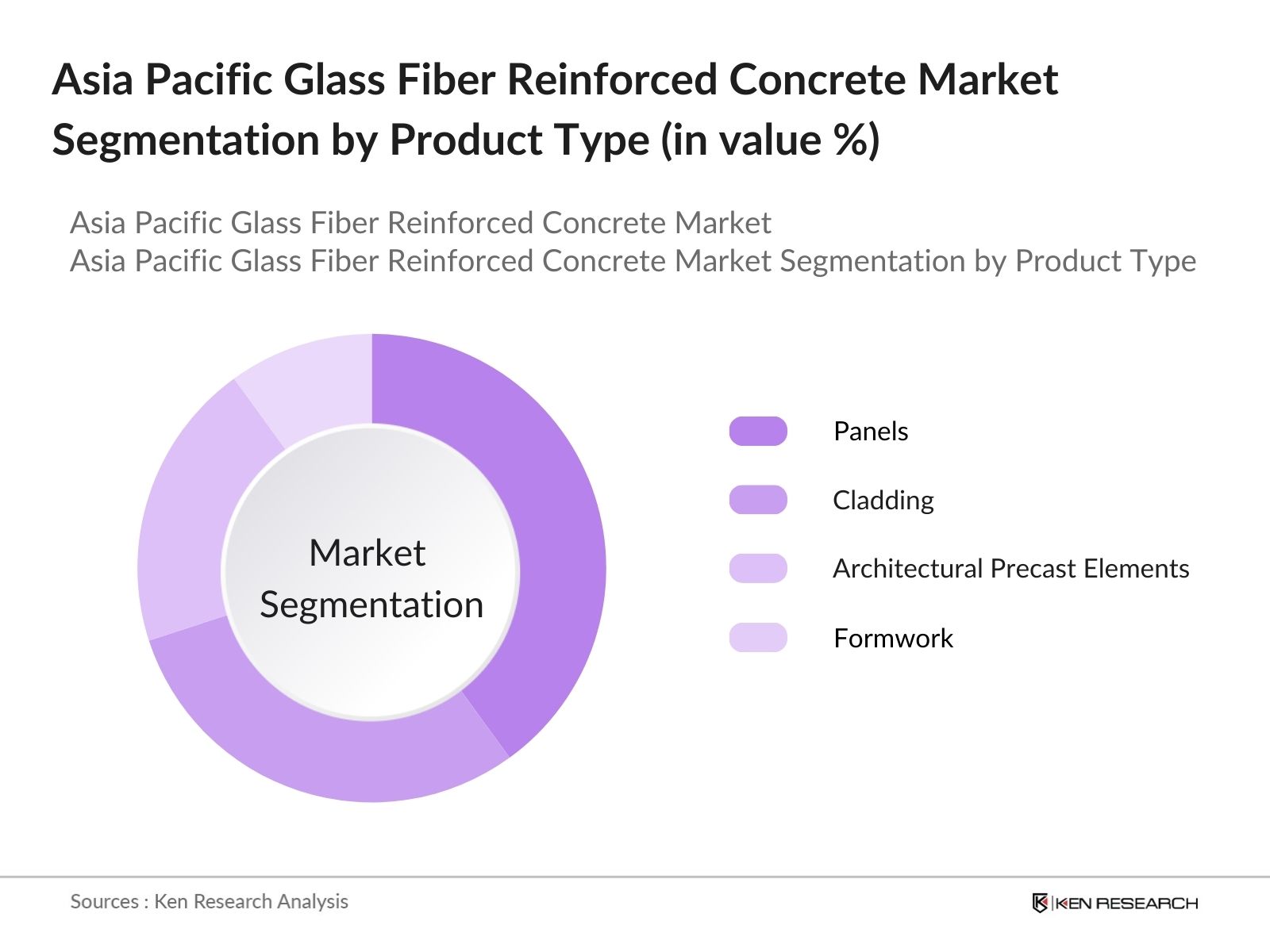

By Product Type: The Asia Pacific GFRC market is segmented by product type into panels, cladding, and architectural precast elements. Recently, panels have a dominant market share due to their widespread use in high-rise buildings and infrastructure projects. Their lightweight nature, combined with high durability, makes them ideal for construction in seismic zones, which is critical in regions like Japan and Indonesia. Panels also offer easy customization and installation, making them the preferred choice in fast-growing urban centers.

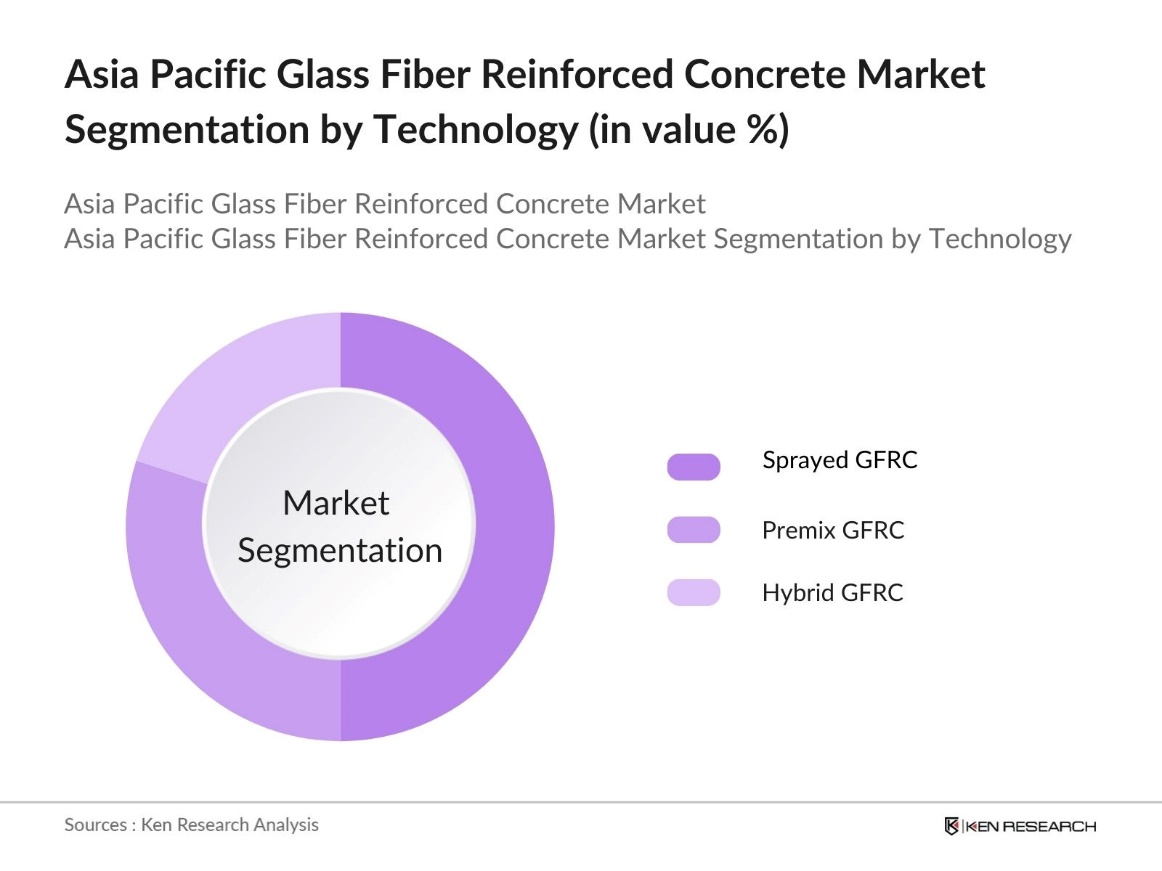

By Technology: The Asia Pacific GFRC market is segmented by technology into sprayed GFRC, premix GFRC, and hybrid GFRC. Sprayed GFRC holds the dominant market share due to its versatility in applications and ability to create thin, strong structures with minimal material usage. This method is favored in large-scale commercial and infrastructure projects, where cost-efficiency and durability are critical. Sprayed GFRC is commonly used in architectural facades and precast elements in high-demand markets like China and Australia.

Asia Pacific Glass Fiber Reinforced Concrete Market Competitive Landscape

The market is dominated by key players that have established a significant presence in the region, focusing on sustainable construction materials and advanced building technologies. The major players include local manufacturers and global companies with a strong foothold in the construction materials industry. This consolidation highlights the significant influence these companies have in driving innovation and meeting the growing demand for eco-friendly building solutions.

|

Company Name |

Establishment Year |

Headquarters |

Production Capacity |

R&D Investments |

Geographical Reach |

Sustainability Initiatives |

Customer Base |

Strategic Partnerships |

|

Ultratech Cement |

1983 |

India |

||||||

|

Willis Construction Co., Inc. |

1972 |

USA |

||||||

|

Nanjing Beilida New Material Co. |

1996 |

China |

||||||

|

BB Fiberbeton |

1986 |

Denmark |

||||||

|

Formglas Products Ltd. |

1961 |

Canada |

Asia Pacific Glass Fiber Reinforced Concrete Industry Analysis

Growth Drivers

- Urbanization (Infrastructure Expansion, Building Applications): Urbanization is driver for this market in the Asia Pacific region, as countries like China and India continue to invest heavily in infrastructure. The NIP is integral to India's goal of becoming a $5 trillion economy by 2025. To achieve this, an estimated $4.5 trillion is required for infrastructure development through 2030. The market benefits directly from the surge in urban housing and commercial real estate projects. The rapid construction of urban residential areas and office buildings drives the demand for GFRC panels and facades due to their durability and lightweight nature.

- Sustainability Focus (Eco-friendly Construction Materials): With a strong focus on sustainability, the Asia Pacific construction sector is adopting eco-friendly materials like GFRC. GFRC is known for its lower carbon footprint and high recyclability compared to traditional concrete. The Green Building Council Indonesia (GBCI) has developed a certification system known as GREENSHIP, which assesses buildings based on criteria. For instance, Jakarta's previous regulations mandated solar panel installations on certain buildings but were revoked in December 2023 to align with national standards.

- Technological Advancements: Technological advancements in GFRC formulations have enhanced its durability, strength, and weather resistance, making it ideal for diverse construction applications. These improvements, driven by innovations in manufacturing processes, result in stronger and lighter materials. As a result, the adoption of GFRC is accelerating across infrastructure and commercial projects, particularly in regions where performance and sustainability are increasingly prioritized in modern construction practices.

Market Challenges

- High Production Costs: The high production costs of GFRC hinder its widespread adoption in the Asia Pacific construction market. GFRC production requires specialized equipment and labor-intensive processes, which increases overall expenses compared to traditional materials like concrete. This cost factor poses a challenge, especially in cost-sensitive markets where affordability is crucial. As a result, the broader use of GFRC is limited, making it less accessible for large-scale construction projects in the region.

- Limited Awareness Among Architects and Engineers: Limited awareness of GFRC among architects and engineers in emerging economies remains a key challenge to its adoption. Many construction professionals in countries like Vietnam and the Philippines continue to rely on traditional materials due to unfamiliarity with the benefits of GFRC, such as its strength and lightweight nature. To overcome this barrier, increased education and training initiatives will be necessary to promote wider usage of GFRC in construction projects.

Asia Pacific Glass Fiber Reinforced Concrete Market Future Outlook

The Asia Pacific GFRC market is expected to continue growing due to increasing government support for sustainable building practices, technological advancements in construction materials, and rising demand for cost-efficient and durable materials in infrastructure development. The growing urbanization in developing economies like India and Southeast Asian countries, coupled with the need for earthquake-resistant and environmentally friendly materials, will further drive market expansion. The shift towards prefabricated and modular construction methods will also boost demand for GFRC.

Market Opportunities

- Rising Demand in Emerging Economies (Construction Boom in APAC): The ongoing construction boom in emerging economies such as India, Indonesia, and Vietnam offers substantial opportunities for the GFRC market. As these countries focus on urbanization and infrastructure development, the demand for sustainable and innovative building materials like GFRC is expected to grow. With numerous residential, commercial, and industrial projects underway, GFRC is well-positioned to become a preferred material in construction applications across the region.

- Expansion of Smart City Projects: The expansion of smart city initiatives throughout the Asia Pacific region presents another growth opportunity for GFRC manufacturers. Countries are increasingly investing in the development of smart cities that emphasize eco-friendly and sustainable building materials. GFRC, with its lightweight, fire-resistant properties, is ideally suited for these projects, where sustainability and innovation are top priorities in urban development.

Scope of the Report

|

By Product Type |

Panels Cladding Architectural Precast Elements Formwork |

|

By Application |

Residential Commercial Infrastructure Industrial |

|

By Technology |

Sprayed GFRC Premix GFRC Hybrid GFRC |

|

By End-User |

Real Estate Developers Architectural Firms Government Bodies Construction Companies |

|

By Region |

China India Japan Australia Rest of Asia Pacific |

Products

Key Target Audience

Architectural Firms

Construction Companies

Pre-fabrication Companies

Investors and venture capital Firms

Banks and Financial Institutions

Government and Regulatory Bodies (China Ministry of Housing, India Ministry of Urban Development)

Companies

Players Mentioned in the Report

Ultratech Cement

Willis Construction Co., Inc.

Nanjing Beilida New Material System Engineering Co., Ltd.

BB Fiberbeton

Formglas Products Ltd.

Clark Pacific

Forta Corporation

Frey-Fil Corporation

Surecrete Design Products

Fishstone Studio Inc.

Table of Contents

1. Asia Pacific GFRC Market Overview

1.1. Definition and Scope

1.2. Market Taxonomy (Market Components, Types of Fibers, Matrix Materials)

1.3. Market Growth Rate (Growth Trajectory, CAGR Drivers)

1.4. Market Segmentation Overview

2. Asia Pacific GFRC Market Size (In USD Bn)

2.1. Historical Market Size

2.2. Year-On-Year Growth Analysis (Revenue Analysis, Volume Metrics)

2.3. Key Market Developments and Milestones

3. Asia Pacific GFRC Market Analysis

3.1. Growth Drivers

3.1.1. Urbanization (Infrastructure Expansion, Building Applications)

3.1.2. Sustainability Focus (Eco-friendly Construction Materials)

3.1.3. Technological Advancements (Improved GFRC Formulations, Performance)

3.1.4. Government Policies (Green Building Initiatives, Environmental Regulations)

3.2. Market Challenges

3.2.1. High Production Costs

3.2.2. Limited Awareness Among Architects and Engineers

3.2.3. Supply Chain Complexity (Raw Material Procurement, Logistics)

3.3. Opportunities

3.3.1. Rising Demand in Emerging Economies (Construction Boom in APAC)

3.3.2. Expansion of Smart City Projects

3.3.3. Product Customization and Applications (Facade Panels, Decorative Elements)

3.4. Trends

3.4.1. Use of Lightweight Building Materials

3.4.2. Pre-fabrication and Modular Construction

3.4.3. Adoption of Fiber-reinforced Materials in Infrastructure

3.5. Government Regulation

3.5.1. Building Material Codes (Fire-Resistant, Load-Bearing Standards)

3.5.2. Sustainability Certification Programs (LEED, Green Star)

3.5.3. Environmental Impact Regulations (Carbon Footprint, Waste Management)

3.6. SWOT Analysis

3.7. Stakeholder Ecosystem (Construction Companies, Architects, Suppliers)

3.8. Porters Five Forces Analysis

3.9. Competition Ecosystem

4. Asia Pacific GFRC Market Segmentation

4.1. By Product Type (In Value %)

4.1.1. Panels

4.1.2. Cladding

4.1.3. Architectural Precast Elements

4.1.4. Formwork

4.2. By Application (In Value %)

4.2.1. Residential

4.2.2. Commercial

4.2.3. Infrastructure

4.2.4. Industrial

4.3. By Technology (In Value %)

4.3.1. Sprayed GFRC

4.3.2. Premix GFRC

4.3.3. Hybrid GFRC

4.4. By End-User (In Value %)

4.4.1. Real Estate Developers

4.4.2. Architectural Firms

4.4.3. Government Bodies

4.4.4. Construction Companies

4.5. By Region (In Value %)

4.5.1. China

4.5.2. India

4.5.3. Japan

4.5.4. Australia

4.5.5. Rest of Asia Pacific

5. Asia Pacific GFRC Market Competitive Analysis

5.1. Detailed Profiles of Major Companies

5.1.1. Ultratech Cement

5.1.2. Formglas Products Ltd.

5.1.3. Willis Construction Co., Inc.

5.1.4. Clark Pacific

5.1.5. Frey-Fil Corporation

5.1.6. BB Fiberbeton

5.1.7. Nanjing Beilida New Material System Engineering Co., Ltd.

5.1.8. Forta Corporation

5.1.9. Fishstone Studio Inc.

5.1.10. Surecrete Design Products

5.1.11. Betofiber Concrete Solutions

5.1.12. Jiangsu Jingwei Fiberglass Co., Ltd.

5.1.13. Conserv Group

5.1.14. LafargeHolcim Ltd.

5.1.15. GFRC Construction Co.

5.2. Cross Comparison Parameters (Market Penetration, Product Portfolio, R&D Investments, Geographical Reach, Sustainability Initiatives, Manufacturing Capacity, Customer Base, Strategic Partnerships)

5.3. Market Share Analysis

5.4. Strategic Initiatives

5.5. Mergers and Acquisitions

5.6. Investment Analysis

5.7. Venture Capital Funding

5.8. Government Grants

5.9. Private Equity Investments

6. Asia Pacific GFRC Market Regulatory Framework

6.1. Building Material Regulations

6.2. Compliance Requirements

6.3. Certification Processes

7. Asia Pacific GFRC Market Future Market Size (In USD Bn)

7.1. Future Market Size Projections

7.2. Key Factors Driving Future Market Growth

8. Asia Pacific GFRC Market Future Market Segmentation

8.1. By Product Type (In Value %)

8.2. By Application (In Value %)

8.3. By Technology (In Value %)

8.4. By End-User (In Value %)

8.5. By Region (In Value %)

9. Asia Pacific GFRC Market Analysts Recommendations

9.1. TAM/SAM/SOM Analysis

9.2. Customer Cohort Analysis

9.3. Marketing Initiatives

9.4. White Space Opportunity Analysis

Disclaimer Contact UsResearch Methodology

Step 1: Identification of Key Variables

The initial step involved constructing an ecosystem map of all stakeholders in the Asia Pacific GFRC Market. Desk research was conducted using proprietary and secondary databases to gather industry-level data, focusing on market dynamics, drivers, and challenges.

Step 2: Market Analysis and Construction

Historical data was compiled and analyzed for market penetration, product adoption rates, and market revenue. This involved examining the ratio of suppliers to buyers and evaluating market demand trends across different geographies.

Step 3: Hypothesis Validation and Expert Consultation

The next phase involved validating market hypotheses through expert consultations. Industry professionals from various construction and materials companies were interviewed to gain insights into market behavior and future projections.

Step 4: Research Synthesis and Final Output

Finally, direct engagements with GFRC manufacturers and construction companies helped in verifying the bottom-up market data. This process ensured the accuracy and reliability of the report findings.

Frequently Asked Questions

01 How big is the Asia Pacific GFRC Market?

The Asia Pacific GFRC Market is valued at USD 0.54 billion, with growth driven by the demand for eco-friendly construction materials and increasing urbanization.

04 What are the challenges in the Asia Pacific GFRC Market?

Challenges in Asia Pacific GFRC Market include high production costs, limited awareness among builders and architects, and the complex supply chain for raw materials and manufacturing processes.

03 Who are the major players in the Asia Pacific GFRC Market?

Key players in Asia Pacific GFRC Market include Ultratech Cement, Willis Construction Co., Inc., Nanjing Beilida New Material System Engineering Co., Ltd., BB Fiberbeton, and Formglas Products Ltd.

04 What are the growth drivers of the Asia Pacific GFRC Market?

The Asia Pacific GFRC Market is propelled by factors such as government support for green building initiatives, advancements in material technology, and the rising demand for lightweight, durable materials in construction.

Why Buy From Us?

What makes us stand out is that our consultants follows Robust, Refine and Result (RRR) methodology. i.e. Robust for clear definitions, approaches and sanity checking, Refine for differentiating respondents facts and opinions and Result for presenting data with story

We have set a benchmark in the industry by offering our clients with syndicated and customized market research reports featuring coverage of entire market as well as meticulous research and analyst insights.

While we don't replace traditional research, we flip the method upside down. Our dual approach of Top Bottom & Bottom Top ensures quality deliverable by not just verifying company fundamentals but also looking at the sector and macroeconomic factors.

With one step in the future, our research team constantly tries to show you the bigger picture. We help with some of the tough questions you may encounter along the way: How is the industry positioned? Best marketing channel? KPI's of competitors? By aligning every element, we help maximize success.

Our report gives you instant access to the answers and sources that other companies might choose to hide. We elaborate each steps of research methodology we have used and showcase you the sample size to earn your trust.

If you need any support, we are here! We pride ourselves on universe strength, data quality, and quick, friendly, and professional service.