Asia Pacific Injection Molding Plastic Market Outlook to 2030

Region:Asia

Author(s):Sanjna

Product Code:KROD10345

December 2024

86

About the Report

Asia Pacific Injection Molding Plastic Market Overview

- The Asia Pacific Injection Molding Plastic Market, valued at USD 187 billion, shows consistent growth driven by increasing demand across industries such as automotive, consumer electronics, and packaging. With the region's robust manufacturing infrastructure, particularly in China, Japan, and India, the adoption of injection molding technology for efficient, high-volume plastic part production continues to rise.

- Dominant markets in this sector include China, Japan, and South Korea. China stands out due to its established infrastructure, skilled labor, and supportive governmental policies aimed at bolstering its plastic production sector. Japans dominance is rooted in its precision manufacturing capabilities and emphasis on advanced, automated machinery, which aligns well with injection molding plastic processes.

- Environmental regulations, including emissions and waste management standards, are tightening across Asia-Pacific. For instance, Chinas new Zero Waste Cities initiative mandates a 50% reduction in industrial plastic waste by 2025. These regulations impact injection molding companies by enforcing strict waste management and emissions targets, particularly affecting manufacturers of single-use plastics.

Asia Pacific Injection Molding Plastic Market Segmentation

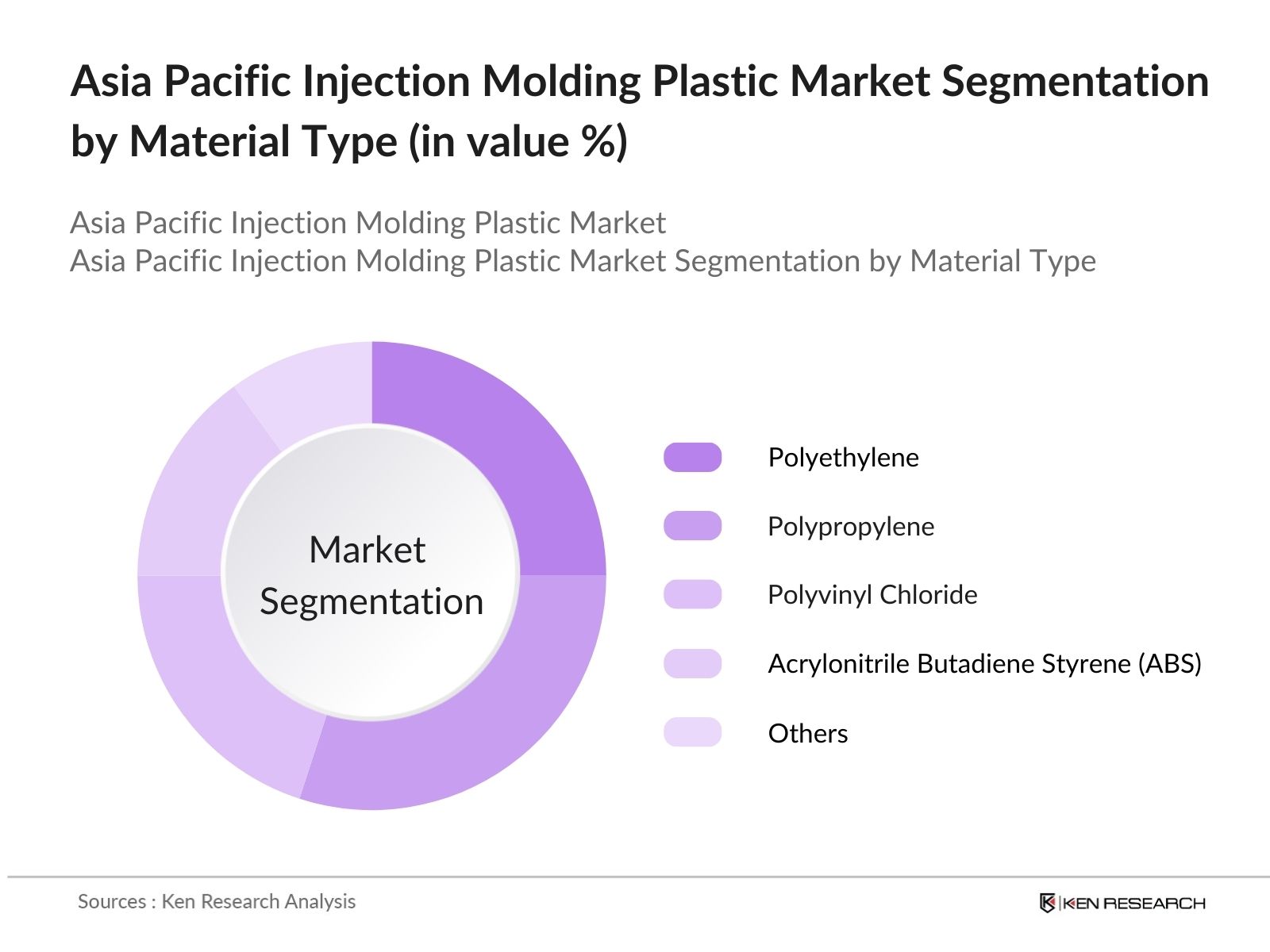

By Material Type: The Asia Pacific Injection Molding Plastic Market is segmented by material type into Polyethylene, Polypropylene, Polyvinyl Chloride (PVC), Acrylonitrile Butadiene Styrene (ABS), and others. Recently, Polypropylene holds the dominant share under material type segmentation due to its flexibility and extensive applications across automotive, packaging, and consumer goods. Known for its durability and adaptability, polypropylene remains a preferred choice among manufacturers, especially for high-volume production in packaging and consumer electronics.

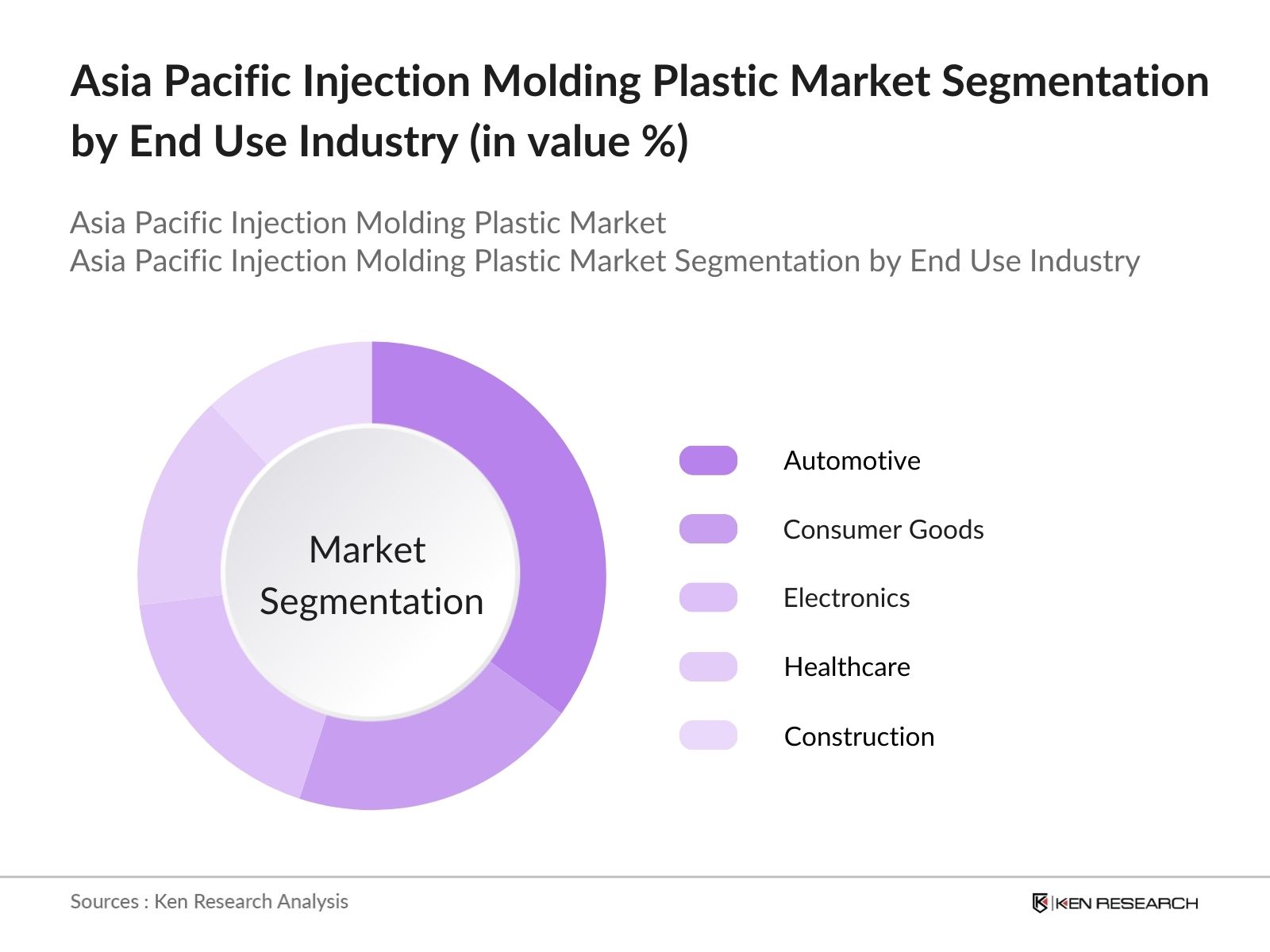

By End-Use Industry: The market is further segmented by end-use industry, comprising Automotive, Consumer Goods, Electronics, Healthcare, and Construction. The Automotive segment leads this categorization, attributed to rising demand for lightweight, durable components that enhance vehicle fuel efficiency. With stringent regulations on emissions, automotive manufacturers in Asia Pacific are leveraging injection molding plastics to produce parts that reduce vehicle weight, thereby enhancing fuel economy.

Asia Pacific Injection Molding Plastic Market Competitive Landscape

The Asia Pacific Injection Molding Plastic Market is dominated by several key players with strong regional presence and manufacturing capabilities. Major companies operate in a consolidated landscape, focusing on strategic investments and technological advancements to maintain competitive positions.

Asia Pacific Injection Molding Plastic Market Analysis

Growth Drivers

- Increasing Demand from Automotive Sector: According to the International Energy Agency (IEA), the Asia-Pacific region produced approximately 51.8 million vehicles in 2023, accounting for over 60% of global production, underscoring the need for durable, lightweight materials in vehicles to meet fuel efficiency standards. This industry growth directly drives injection-molded plastics demand, as manufacturers rely on high-performance plastics for both structural and aesthetic automotive applications, particularly in countries like China and India, which dominate production volumes.

- Rise in Consumer Electronics Manufacturing: Asia-Pacific is a global manufacturing hub for consumer electronics, with over 3.5 billion electronic units, such as smartphones and laptops, produced annually, especially in countries like China, South Korea, and Japan. Injection-molded plastics are crucial for producing lightweight, durable components for these devices, with the region's market benefiting from consistent consumer demand.

- Expansion of Medical Device Applications: In response to growing healthcare needs, medical device manufacturing in the region is rapidly increasing, driving demand for injection-molded plastics Countries like India, which recently invested $2 billion into medical technology parks, are focused on cost-effective, high-quality production of medical supplies and devices, often using injection-molded plastic components for their safety, sterility, and lightweight properties.

Challenges

- High Energy Consumption: Injection molding is energy-intensive, requiring significant electricity to maintain production speed and quality, especially in the high-output factories of China and Japan. As per the International Energy Agency (IEA), industrial energy use in Asia-Pacific increased by 4.2% in 2023, pushing operational costs higher for plastic manufacturers. This reliance on energy-intensive processes presents sustainability challenges as the sector faces increasing scrutiny to reduce carbon emissions, particularly in manufacturing hubs with strict environmental policies like Japan.

- Rising Raw Material Prices: The prices of raw materials, such as polypropylene and polyethylene, used in injection molding have increased by 8% on average across the Asia-Pacific region in 2023, driven by global supply chain disruptions. According to the World Bank, these materials price fluctuations are expected to remain volatile, impacting the cost structure for injection-molding plastic manufacturers. The reliance on imports for certain resins, particularly in Southeast Asia, intensifies the regions vulnerability to price hikes.

Asia Pacific Injection Molding Plastic Market Future Outlook

The Asia Pacific Injection Molding Plastic Market is expected to exhibit substantial growth over the next five years, driven by increased demand across the automotive, consumer goods, and healthcare sectors. This growth trajectory is supported by continuous advancements in injection molding technology, the introduction of bio-based and recycled plastics, and evolving regulatory frameworks promoting sustainable production practices.

Market Opportunities

- Bio-Based and Recycled Plastics: Increasing environmental awareness and regulatory pressure are accelerating the shift towards bio-based and recycled plastics in injection molding. The Asia-Pacific market witnessed the introduction of over 2 million tons of recycled plastics into production processes in 2023, with Japan and China leading in adoption. Governments, such as Chinas, incentivize bio-based plastic alternatives through subsidies to reduce reliance on traditional polymers. This market shift supports sustainable manufacturing while meeting regulatory standards.

- Emerging Applications in Packaging: The demand for sustainable packaging solutions is driving innovation in injection-molded plastics within Asia-Pacific. In 2023, the Asia-Pacific packaging industry produced over 120 billion units, with a significant portion utilizing sustainable plastic alternatives, according to the Asian Packaging Federation. Injection molding enables cost-effective and durable packaging solutions, supporting the shift towards environmentally friendly materials and advanced designs to meet consumer and regulatory demands.

Scope of the Report

|

Segment |

Sub-Segments |

|

Material Type |

Polyethylene Polypropylene PVC ABS Others |

|

End-Use Industry |

Automotive Consumer Goods Electronics Healthcare Construction |

|

Technology |

Hydraulic Injection Molding Electric Injection Molding Hybrid Injection Molding |

|

Application |

Interior Parts Housing and Frames Packaging Solutions Medical Devices Structural Components |

|

Country |

China Japan India South Korea Australia |

Products

Key Target Audience

Plastic Manufacturers

Automotive OEMs

Consumer Electronics Companies

Healthcare Equipment Manufacturers

Construction Material Providers

Injection Molding Machine Manufacturers

Investors and Venture Capitalist Firms

Government and Regulatory Bodies (e.g., Ministry of Industry and Information Technology, Environmental Protection Agency)

Companies

Players Mentioned in the Report

Mitsubishi Chemical Corporation

Toray Industries, Inc.

Asahi Kasei Corporation

Sumitomo Chemical Co., Ltd.

LG Chem Ltd.

BASF SE

SABIC (Saudi Basic Industries Corporation)

Lotte Chemical Corporation

Formosa Plastics Corporation

Reliance Industries Limited

Table of Contents

1. Asia Pacific Injection Molding Plastic Market Overview

1.1. Definition and Scope

1.2. Market Taxonomy

1.3. Industry Ecosystem Overview

1.4. Key Stakeholders Analysis

2. Asia Pacific Injection Molding Plastic Market Size (In USD Mn)

2.1. Historical Market Size Analysis

2.2. Year-On-Year Growth Analysis

2.3. Key Industry Developments and Milestones

3. Asia Pacific Injection Molding Plastic Market Analysis

3.1. Growth Drivers (Material Performance, Process Efficiency)

3.1.1. Increasing Demand from Automotive Sector

3.1.2. Rise in Consumer Electronics Manufacturing

3.1.3. Expansion of Medical Device Applications

3.1.4. Growth in Construction Sector

3.2. Market Challenges (Cost Factors, Environmental Concerns)

3.2.1. High Energy Consumption

3.2.2. Rising Raw Material Prices

3.2.3. Waste Management Regulations

3.3. Opportunities (Innovation, Regional Demand Shift)

3.3.1. Bio-Based and Recycled Plastics

3.3.2. Emerging Applications in Packaging

3.3.3. Technological Advancements in Machinery

3.4. Trends (Sustainability, Digital Integration)

3.4.1. Adoption of Electric Injection Molding Machines

3.4.2. Integration of IoT for Real-Time Monitoring

3.4.3. Shift Towards Sustainable Materials

3.5. Regulatory Landscape

3.5.1. Environmental Regulations (Emissions, Waste)

3.5.2. Compliance Standards for Plastics Manufacturing

3.5.3. Trade Policies Affecting Raw Material Imports

3.6. SWOT Analysis

3.7. Competitive Landscape Assessment

3.8. Porters Five Forces Analysis

4. Asia Pacific Injection Molding Plastic Market Segmentation

4.1. By Material Type (In Value %)

4.1.1. Polyethylene

4.1.2. Polypropylene

4.1.3. Polyvinyl Chloride (PVC)

4.1.4. Acrylonitrile Butadiene Styrene (ABS)

4.1.5. Others

4.2. By End-Use Industry (In Value %)

4.2.1. Automotive

4.2.2. Consumer Goods

4.2.3. Electronics

4.2.4. Healthcare

4.2.5. Construction

4.3. By Technology (In Value %)

4.3.1. Hydraulic Injection Molding

4.3.2. Electric Injection Molding

4.3.3. Hybrid Injection Molding

4.4. By Application (In Value %)

4.4.1. Interior Parts

4.4.2. Housing and Frames

4.4.3. Packaging Solutions

4.4.4. Medical Devices and Components

4.4.5. Structural Building Components

4.5. By Country

4.5.1. China

4.5.2. Japan

4.5.3. India

4.5.4. South Korea

4.5.5. Australia

5. Asia Pacific Injection Molding Plastic Market Competitive Analysis

5.1. Detailed Profiles of Major Companies

5.1.1. Mitsubishi Chemical Corporation

5.1.2. Toray Industries, Inc.

5.1.3. Asahi Kasei Corporation

5.1.4. Sumitomo Chemical Co., Ltd.

5.1.5. LG Chem Ltd.

5.1.6. Formosa Plastics Corporation

5.1.7. BASF SE

5.1.8. SABIC (Saudi Basic Industries Corporation)

5.1.9. Lotte Chemical Corporation

5.1.10. Reliance Industries Limited

5.2. Cross Comparison Parameters (R&D Expenditure, Production Capacity, Material Specialization, Revenue, Regional Presence, Environmental Compliance, Supply Chain Strength, Technology Adoption)

5.3. Market Share Analysis

5.4. Strategic Initiatives

5.5. Mergers and Acquisitions

5.6. Investment Analysis

5.7. Key Partnerships and Collaborations

6. Asia Pacific Injection Molding Plastic Market Regulatory Framework

6.1. Environmental Standards

6.2. Product and Material Certification Requirements

6.3. Trade Tariffs and Import Policies

7. Asia Pacific Injection Molding Plastic Future Market Size (In USD Mn)

7.1. Future Market Size Projections

7.2. Factors Driving Future Market Expansion

8. Asia Pacific Injection Molding Plastic Future Market Segmentation

8.1. By Material Type (In Value %)

8.2. By End-Use Industry (In Value %)

8.3. By Technology (In Value %)

8.4. By Application (In Value %)

8.5. By Country

9. Asia Pacific Injection Molding Plastic Market Analysts Recommendations

9.1. TAM/SAM/SOM Analysis

9.2. Strategic Market Positioning

9.3. Technology Investment Recommendations

9.4. Sustainability and Regulatory Compliance Opportunities

Disclaimer Contact UsResearch Methodology

Step 1: Identification of Key Variables

The initial stage involves creating a comprehensive ecosystem map, identifying primary stakeholders across the Asia Pacific Injection Molding Plastic Market. Extensive desk research and proprietary databases provide foundational insights into critical market dynamics.

Step 2: Market Analysis and Construction

In this phase, historical data is compiled and analyzed, with a focus on evaluating key market trends and identifying the balance between product manufacturers and end-use industries. Additionally, analysis of the regional distribution of market players is conducted to ensure accurate revenue estimates.

Step 3: Hypothesis Validation and Expert Consultation

Developed market hypotheses are validated through in-depth interviews with industry experts, providing insights into operational and financial practices across key companies, and refining data accuracy and reliability.

Step 4: Research Synthesis and Final Output

Final analysis incorporates feedback from multiple plastic manufacturing companies, providing valuable insights on production trends, consumer preferences, and segment performance. This enhances the reliability of projections for the Asia Pacific Injection Molding Plastic Market.

Frequently Asked Questions

01. How big is the Asia Pacific Injection Molding Plastic Market?

The Asia Pacific Injection Molding Plastic Market is valued at USD 187 billion, driven by strong demand in automotive and consumer goods sectors.

02. What are the challenges in the Asia Pacific Injection Molding Plastic Market?

Challenges in Asia Pacific Injection Molding Plastic Market include high energy consumption, rising raw material prices, and stringent waste management regulations across the region.

03. Who are the major players in the Asia Pacific Injection Molding Plastic Market?

Key players in Asia Pacific Injection Molding Plastic Market include Mitsubishi Chemical Corporation, Toray Industries, Asahi Kasei Corporation, Sumitomo Chemical, and LG Chem, noted for their extensive R&D and regional influence.

04. What are the growth drivers of the Asia Pacific Injection Molding Plastic Market?

Growth in Asia Pacific Injection Molding Plastic Market is fueled by demand in automotive and consumer electronics industries, supported by evolving manufacturing capabilities and regional government initiatives for local production.

Why Buy From Us?

What makes us stand out is that our consultants follows Robust, Refine and Result (RRR) methodology. i.e. Robust for clear definitions, approaches and sanity checking, Refine for differentiating respondents facts and opinions and Result for presenting data with story

We have set a benchmark in the industry by offering our clients with syndicated and customized market research reports featuring coverage of entire market as well as meticulous research and analyst insights.

While we don't replace traditional research, we flip the method upside down. Our dual approach of Top Bottom & Bottom Top ensures quality deliverable by not just verifying company fundamentals but also looking at the sector and macroeconomic factors.

With one step in the future, our research team constantly tries to show you the bigger picture. We help with some of the tough questions you may encounter along the way: How is the industry positioned? Best marketing channel? KPI's of competitors? By aligning every element, we help maximize success.

Our report gives you instant access to the answers and sources that other companies might choose to hide. We elaborate each steps of research methodology we have used and showcase you the sample size to earn your trust.

If you need any support, we are here! We pride ourselves on universe strength, data quality, and quick, friendly, and professional service.