Asia Pacific Pneumatic Actuators Market Outlook to 2030

Region:Asia

Author(s):Meenakshi

Product Code:KROD3395

November 2024

96

About the Report

Asia Pacific Pneumatic Actuators Market Overview

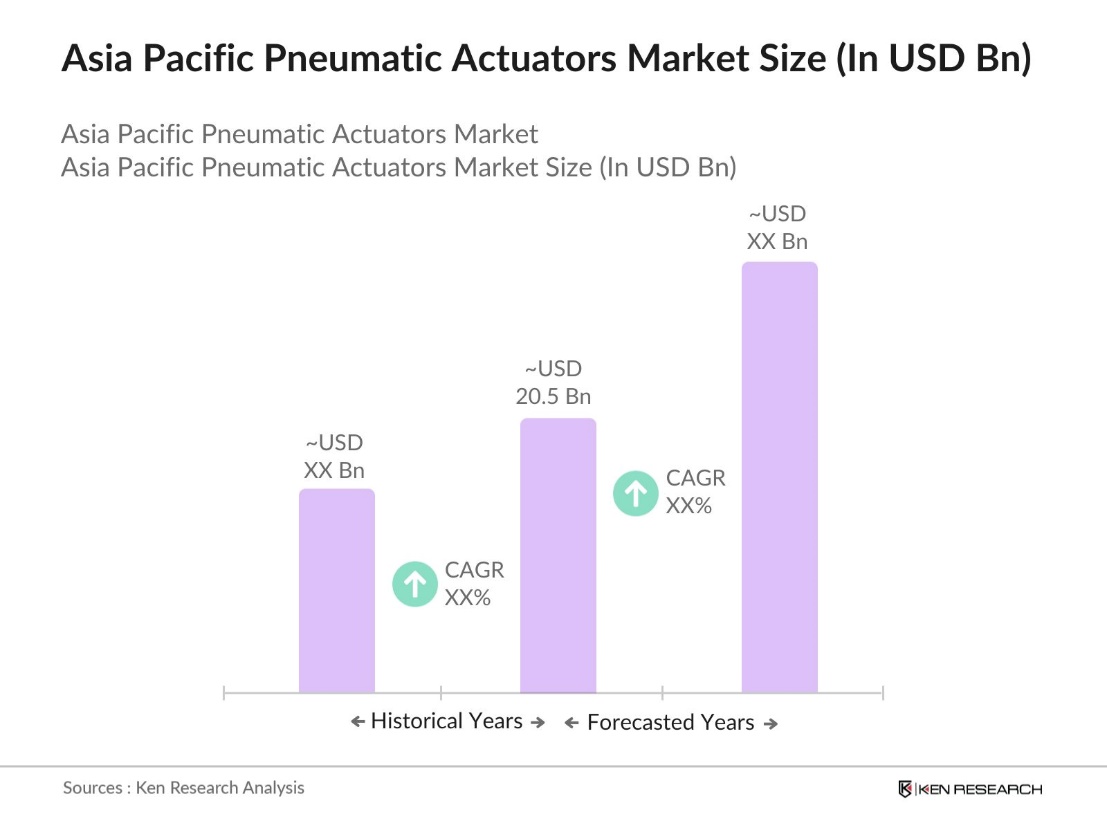

- The Asia Pacific Pneumatic Actuators market is valued at USD 20.5 billion, driven by rapid industrialization and the demand for process automation across key sectors such as energy and automotive. The market has seen steady growth, supported by the increasing adoption of automated technologies in manufacturing processes and the ongoing shift toward energy-efficient systems.

- China, Japan, and South Korea dominate the pneumatic actuators market in the Asia Pacific region. China leads the market due to its large industrial base, high demand for automation in manufacturing, and significant investments in energy infrastructure. Japan and South Korea follow closely, leveraging their advanced technological capabilities and strong automotive sectors. These countries have well-established industries requiring pneumatic solutions for cost-efficient and precise control in manufacturing and production processes.

- Safety guidelines in the industrial sector are becoming increasingly stringent across Asia Pacific, especially in countries like South Korea and Japan. In 2023, Japan's Ministry of Health, Labour, and Welfare (MHLW) proposed revised guidelines for measuring workplace exposure limits for hazardous substances under the Industrial Safety and Health Act (ISHA). These guidelines are pushing companies to invest in high-quality actuators that meet or exceed safety compliance standards.

Asia Pacific Pneumatic Actuators Market Segmentation

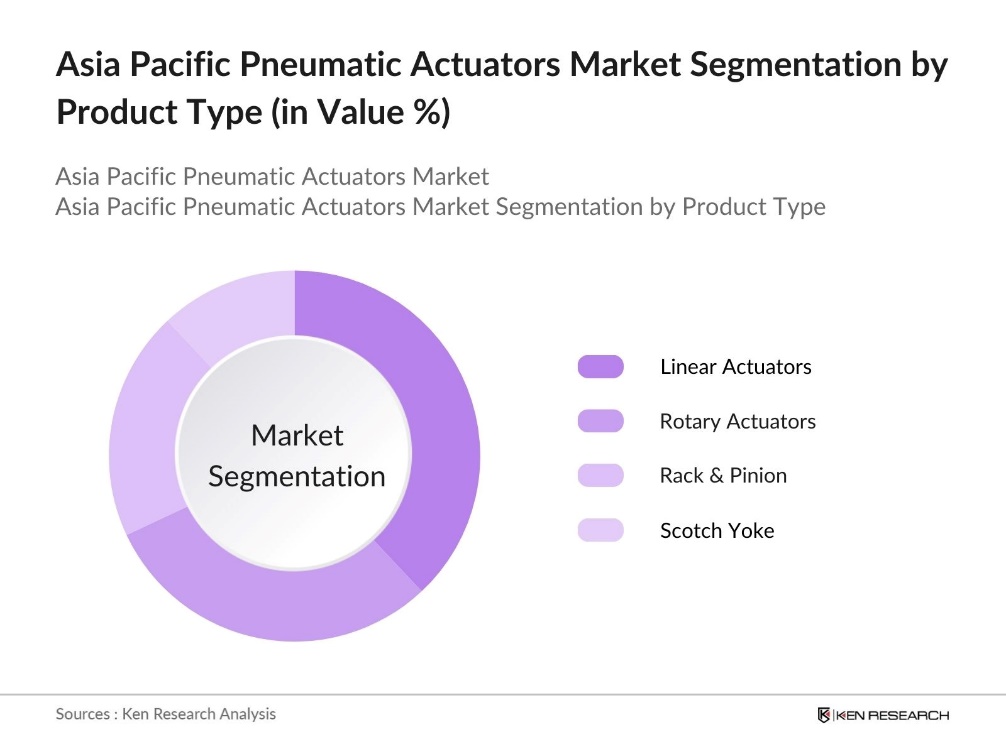

By Product Type: The market is segmented by product type into Linear Actuators, Rotary Actuators, Rack & Pinion Actuators, and Scotch Yoke Actuators. Recently, Linear Actuators have a dominant market share within this segment due to their wide applicability across industries, including oil and gas, chemical processing, and automotive manufacturing. The ability of linear actuators to offer precise control, reliability in harsh environments, and their relatively low cost of maintenance makes them a preferred choice among manufacturers in these sectors.

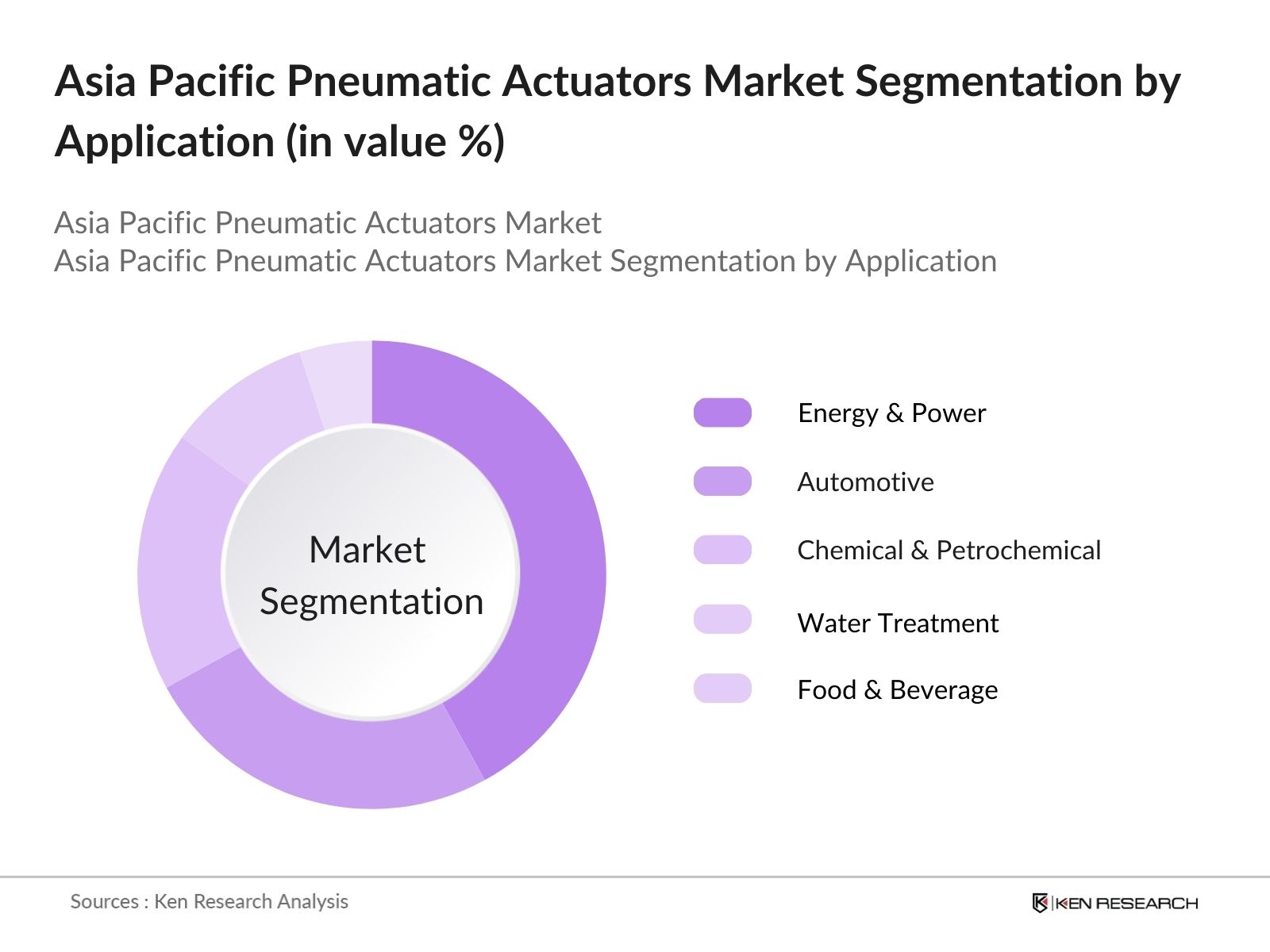

By Application: The market is segmented by application into Energy & Power, Automotive, Food & Beverage, Chemical & Petrochemical, and Water Treatment. Energy & Power emerges as the leading segment, driven by the need for automation in power generation and the growing focus on renewable energy projects. Pneumatic actuators play a critical role in controlling valves and flow mechanisms, making them essential for power plants, especially in environments where electrical solutions may not be feasible.

Asia Pacific Pneumatic Actuators Market Competitive Landscape

The Asia Pacific Pneumatic Actuators market is characterized by a combination of global and regional players, leading to a competitive yet fragmented market landscape. Major international companies, such as Emerson Electric Co., Festo AG & Co. KG, and SMC Corporation, dominate the market due to their extensive product portfolios, strong distribution networks, and continuous innovation in pneumatic technologies. These companies benefit from economies of scale and have established long-term relationships with key customers in industries such as energy, automotive, and chemical processing.

|

Company |

Establishment Year |

Headquarters |

Production Sites |

Product Portfolio |

R&D Spend |

Patents Filed |

Customer Base |

Regional Focus |

|

Emerson Electric Co. |

1890 |

St. Louis, USA |

||||||

|

Festo AG & Co. KG |

1925 |

Esslingen, Germany |

||||||

|

SMC Corporation |

1959 |

Tokyo, Japan |

||||||

|

Bosch Rexroth AG |

1795 |

Lohr, Germany |

||||||

|

Parker Hannifin Corp. |

1917 |

Cleveland, USA |

Asia Pacific Pneumatic Actuators Industry Analysis

Growth Drivers

- Increasing Demand in Process Automation: The Asia-Pacific region is seeing a surge in process automation driven by industrial manufacturing, where pneumatic actuators are widely used due to their reliability and efficiency. Industrial production in Japan declined by 3.3% month-over-month in August 2024, showcasing the demand for actuators in automated systems, particularly in sectors like chemicals, metals, and electronics. Countries like South Korea also exhibit growing automation adoption in industrial sector.

- Expansion of Energy & Power Sector: The power generation industry in the Asia-Pacific region has been expanding significantly. China generated approximately 8,388.6 terawatt-hours (TWh) of electricity in 2022. Pneumatic actuators play a critical role in controlling valves and dampers in energy infrastructure, helping maintain operational efficiency. The growing demand for power in these countries continues to boost the demand for pneumatic actuators, particularly in power plants and refineries.

- Rising Adoption in Automotive Industry: Asia-Pacifics automotive industry is a major driver of demand for pneumatic actuators, used extensively in processes like material handling, welding, and assembly in vehicle production. As key automotive manufacturing hubs like China, Japan, and India continue to scale up production, the need for efficient automation systems, including pneumatic actuators, is rising. These actuators ensure reliability and efficiency in mass production environments, supporting the industry's ongoing growth.

Market Challenges

- High Maintenance and Repair Costs: Pneumatic actuators require regular upkeep, including the replacement of components such as seals and filters. This ongoing maintenance can lead to increased operational costs, impacting profitability for industries that rely heavily on these systems. As industrial demands grow, the frequency and cost of repairs can rise, making companies more cautious about adopting pneumatic actuators, despite their operational efficiency and advantages in automation.

- Lack of Skilled Workforce: The Asia-Pacific region faces a shortage of skilled workers to manage and maintain advanced pneumatic systems. This gap in expertise forces companies to either outsource maintenance tasks or invest in workforce training, both of which increase operational expenses. The lack of sufficient training programs in some areas further exacerbates this challenge, making it difficult for industries to fully leverage pneumatic technologies.

Asia Pacific Pneumatic Actuators Market Future Outlook

The Asia Pacific Pneumatic Actuators market is expected to grow substantially over the next five years. This growth will be driven by increased investments in industrial automation, the rising demand for energy-efficient solutions, and the expansion of sectors such as renewable energy, oil and gas, and automotive manufacturing. Governments across the region are pushing for more stringent regulations regarding energy consumption and emissions, further fueling the demand for pneumatic actuators, which offer energy-efficient alternatives to electric and hydraulic systems.

Market Opportunities

- Growth in Emerging Economies: Emerging economies like Vietnam and the Philippines are undergoing rapid industrialization, leading to increased demand for automation in sectors such as electronics, textiles, and chemicals. This industrial growth is creating significant opportunities for pneumatic actuator manufacturers as these countries expand their production capabilities. The rise of manufacturing in these markets provides a new avenue for the adoption of automation technologies, driving demand for pneumatic solutions.

- Technological Advancements (e.g., Smart Pneumatics, IIoT Integration): The integration of smart pneumatic systems and the Industrial Internet of Things (IIoT) is revolutionizing manufacturing processes. As industries increasingly adopt smart actuators for real-time data monitoring and control, pneumatic technology is advancing. This trend, particularly prominent in sectors like automotive and electronics, offers significant growth potential, with manufacturers increasingly digitizing their operations to enhance efficiency and precision in production lines.

Scope of the Report

|

Product Type |

Linear Actuators Rotary Actuators Rack & Pinion Actuators Scotch Yoke Actuators |

|

Application |

Energy & Power Automotive Food & Beverage Chemical & Petrochemical Water Treatment |

|

Technology |

Double-Acting Pneumatic Actuators Single-Acting Pneumatic Actuators |

|

Material |

Stainless Steel Aluminum Composite |

|

Region |

China Japan South Korea India |

Products

Key Target Audience

Industrial Automation Manufactures

Automotive OEMs

Energy & Power Sector Companies

Chemical & Petrochemical Industry

Government and Regulatory Bodies (Environmental Protection Agency, Department of Energy)

Investors and venture capital Firms

Banks and Financial Institutions

Companies

Players Mentioned in the Report

Emerson Electric Co.

Festo AG & Co. KG

SMC Corporation

Parker Hannifin Corp.

Bosch Rexroth AG

Rotork Plc

Camozzi Automation

KOSO Kent Introl

Bimba Manufacturing

Air Torque

Table of Contents

1. Asia Pacific Pneumatic Actuators Market Overview

1.1. Definition and Scope

1.2. Market Taxonomy

1.3. Market Growth Rate (Units Sold, Revenue in USD Mn, Installed Base)

1.4. Market Segmentation Overview

2. Asia Pacific Pneumatic Actuators Market Size (In USD Mn)

2.1. Historical Market Size (Revenue, Volume, Installed Base)

2.2. Year-On-Year Growth Analysis (Value % and Volume %)

2.3. Key Market Developments and Milestones

3. Asia Pacific Pneumatic Actuators Market Analysis

3.1. Growth Drivers

3.1.1. Increasing Demand in Process Automation

3.1.2. Expansion of Energy & Power Sector

3.1.3. Rising Adoption in Automotive Industry

3.1.4. Focus on Energy Efficiency & Cost Savings

3.2. Market Challenge

3.2.1. High Maintenance and Repair Costs

3.2.2. Lack of Skilled Workforce

3.2.3. Competitive Pressure from Electric Actuators

3.2.4. Regulatory Compliance Issues

3.3. Opportunities

3.3.1. Growth in Emerging Economies

3.3.2. Technological Advancements (e.g., Smart Pneumatics, IIoT Integration)

3.3.3. Increasing R&D Investments by Key Players

3.3.4. Customization and Modular Solutions

3.4. Trends

3.4.1. Shift Towards Industry 4.0 in Manufacturing

3.4.2. Increasing Adoption of Compact Actuators

3.4.3. Emphasis on Green Actuation Technologies

3.5. Government Regulation

3.5.1. Environmental Standards (Emission Reduction, Safety Norms)

3.5.2. Industrial Safety Guidelines

3.5.3. Certification Processes for Pneumatic Components

3.6. SWOT Analysis (Market-specific: Strengths in Energy Efficiency, Weaknesses in Product Differentiation)

3.7. Stakeholder Ecosystem (Manufacturers, OEMs, Distributors, End-users)

3.8. Porters Five Forces

3.8.1. Bargaining Power of Suppliers

3.8.2. Bargaining Power of Buyers

3.8.3. Threat of Substitutes (Electric and Hydraulic Actuators)

3.8.4. Threat of New Entrants

3.8.5. Competitive Rivalry

3.9. Competition Ecosystem (Tier 1, Tier 2, and Local Manufacturers)

4. Asia Pacific Pneumatic Actuators Market Segmentation

4.1. By Product Type (In Value % and Volume %)

4.1.1. Linear Actuators

4.1.2. Rotary Actuators

4.1.3. Rack & Pinion Actuators

4.1.4. Scotch Yoke Actuators

4.2. By Application (In Value % and Volume %)

4.2.1. Energy & Power

4.2.2. Automotive

4.2.3. Food & Beverage

4.2.4. Chemical & Petrochemical

4.2.5. Water Treatment

4.3. By Technology (In Value % and Volume %)

4.3.1. Double-Acting Pneumatic Actuators

4.3.2. Single-Acting Pneumatic Actuators

4.4. By Material (In Value % and Volume %)

4.4.1. Stainless Steel

4.4.2. Aluminum

4.4.3. Composite

4.5. By Region (In Value % and Volume %)

4.5.1. China

4.5.2. Japan

4.5.3. South Korea

4.5.4. India

4.5.5. Australia

5. Asia Pacific Pneumatic Actuators Market Competitive Analysis

5.1 Detailed Profiles of Major Competitors

5.1.1. Emerson Electric Co.

5.1.2. Festo AG & Co. KG

5.1.3. SMC Corporation

5.1.4. Parker Hannifin Corp.

5.1.5. Bosch Rexroth AG

5.1.6. Rotork Plc

5.1.7. Camozzi Automation

5.1.8. KOSO Kent Introl

5.1.9. Bimba Manufacturing

5.1.10. Air Torque

5.1.11. Bray International, Inc.

5.1.12. AVENTICS GmbH

5.1.13. Auma Riester GmbH

5.1.14. Kinetrol Ltd

5.1.15. Norgren (IMI Precision Engineering)

5.2 Cross Comparison Parameters (Market-specific: No. of Patents Filed, Global Reach, Production Capacity, Market Share, Key Clients, R&D Spend, Strategic Partnerships, Product Portfolio)

5.3. Market Share Analysis (In Value % and Volume %)

5.4. Strategic Initiatives (Collaborations, Partnerships, Product Launches)

5.5. Mergers And Acquisitions

5.6. Investment Analysis (Capex by Key Players)

5.7. Government Grants & Incentives

5.8. Private Equity Investments

6. Asia Pacific Pneumatic Actuators Market Regulatory Framework

6.1. Industry Standards (ISO, IEC, ANSI, and Regional Certifications)

6.2. Compliance Requirements (Safety, Environmental, Performance)

6.3. Certification Processes (CE Marking, RoHS, ATEX)

7. Asia Pacific Pneumatic Actuators Future Market Size (In USD Mn)

7.1. Future Market Size Projections (Value % and Volume %)

7.2. Key Factors Driving Future Market Growth (Industrial Automation, Energy Infrastructure Investments)

8. Asia Pacific Pneumatic Actuators Future Market Segmentation

8.1. By Product Type (In Value % and Volume %)

8.2. By Application (In Value % and Volume %)

8.3. By Technology (In Value % and Volume %)

8.4. By Material (In Value % and Volume %)

8.5. By Region (In Value % and Volume %)

9. Asia Pacific Pneumatic Actuators Market Analysts Recommendations

9.1. TAM/SAM/SOM Analysis

9.2. Customer Cohort Analysis (Purchasing Trends, Buying Cycles, Decision Makers)

9.3. Marketing Initiatives (Channel Strategies, Digital Adoption)

9.4. White Space Opportunity Analysi

Disclaimer Contact UsResearch Methodology

Step 1: Identification of Key Variables

The first step involved constructing an ecosystem map of all the stakeholders in the Asia Pacific Pneumatic Actuators market. Through extensive desk research and analysis of proprietary databases, critical market variables such as revenue drivers, operational capacities, and customer demands were identified.

Step 2: Market Analysis and Construction

Historical data from the past five years was compiled to assess market penetration and revenue generation across different sub-segments. Additionally, key performance indicators (KPIs) such as production capacity, sales volume, and pricing trends were analyzed.

Step 3: Hypothesis Validation and Expert Consultation

Market hypotheses were tested through direct consultations with industry experts, including key decision-makers at pneumatic actuator manufacturers and distributors. These interviews helped refine data and offer real-world insights into current trends and challenges.

Step 4: Research Synthesis and Final Output

Data from manufacturers and other stakeholders were synthesized to produce the final market estimates. This included detailed insights into product segmentation, geographic trends, and competitive dynamics, ensuring a robust and reliable market outlook.

Frequently Asked Questions

01 How big is the Asia Pacific Pneumatic Actuators Market?

The Asia Pacific Pneumatic Actuators market is valued at USD 20.5 billion, driven by growing automation across industries like energy, automotive, and chemical processing.

04 What are the challenges in the Asia Pacific Pneumatic Actuators Market?

Challenges in Asia Pacific Pneumatic Actuators market include high maintenance costs, competition from electric actuators, and the lack of skilled workforce to handle pneumatic systems. Compliance with safety and environmental regulations also presents hurdles.

03 Who are the major players in the Asia Pacific Pneumatic Actuators Market?

Key players in Asia Pacific Pneumatic Actuators market include Emerson Electric Co., Festo AG & Co. KG, SMC Corporation, Parker Hannifin Corp., and Bosch Rexroth AG. These companies dominate the market due to their extensive product offerings and strong presence in industrial automation.

04 What are the growth drivers of the Asia Pacific Pneumatic Actuators Market?

The Asia Pacific Pneumatic Actuators market is primarily driven by the increasing need for industrial automation, particularly in the energy, automotive, and chemical sectors. Technological advancements like smart pneumatics and IIoT integration are also fueling market growth.

Why Buy From Us?

What makes us stand out is that our consultants follows Robust, Refine and Result (RRR) methodology. i.e. Robust for clear definitions, approaches and sanity checking, Refine for differentiating respondents facts and opinions and Result for presenting data with story

We have set a benchmark in the industry by offering our clients with syndicated and customized market research reports featuring coverage of entire market as well as meticulous research and analyst insights.

While we don't replace traditional research, we flip the method upside down. Our dual approach of Top Bottom & Bottom Top ensures quality deliverable by not just verifying company fundamentals but also looking at the sector and macroeconomic factors.

With one step in the future, our research team constantly tries to show you the bigger picture. We help with some of the tough questions you may encounter along the way: How is the industry positioned? Best marketing channel? KPI's of competitors? By aligning every element, we help maximize success.

Our report gives you instant access to the answers and sources that other companies might choose to hide. We elaborate each steps of research methodology we have used and showcase you the sample size to earn your trust.

If you need any support, we are here! We pride ourselves on universe strength, data quality, and quick, friendly, and professional service.