Global High Temperature Insulation Materials Market Overview

- The Global High Temperature Insulation Materials Market is valued at USD 7.6 billion, based on a five-year historical analysis. This growth is primarily driven by the increasing demand for energy-efficient solutions across industries such as petrochemicals, power generation, and aerospace. The adoption of high-temperature insulation materials is accelerating due to their critical role in reducing energy consumption, improving operational efficiency, and supporting sustainability initiatives in high-heat environments.

- Key players in this market include the United States, Germany, and China, which maintain dominance owing to their robust industrial bases, significant infrastructure investments, and ongoing advancements in insulation technology. These countries are recognized for their extensive manufacturing capabilities and proactive adoption of innovative insulation solutions, further solidifying their leadership in the global market.

- The European Union has implemented increasingly stringent regulations aimed at enhancing energy efficiency and reducing carbon emissions in industrial processes. These regulations require the integration of high-performance insulation materials in new installations, driving the adoption of advanced insulation technologies to meet energy-saving targets and environmental standards.

Global High Temperature Insulation Materials Market Segmentation

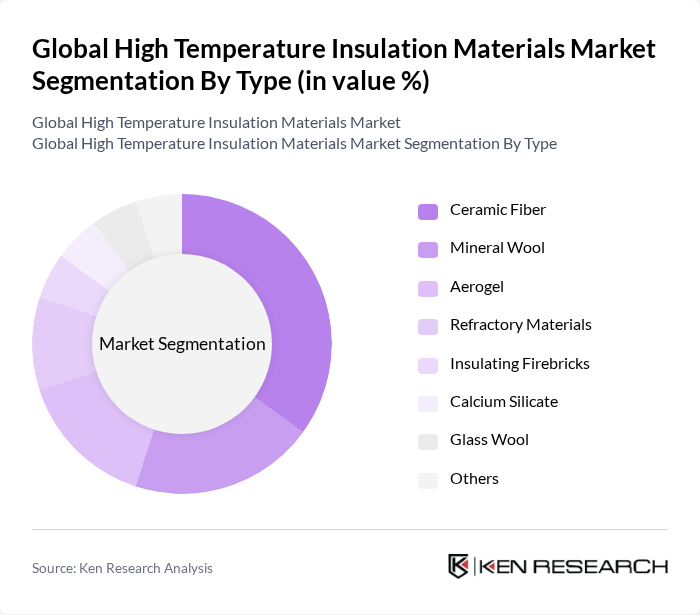

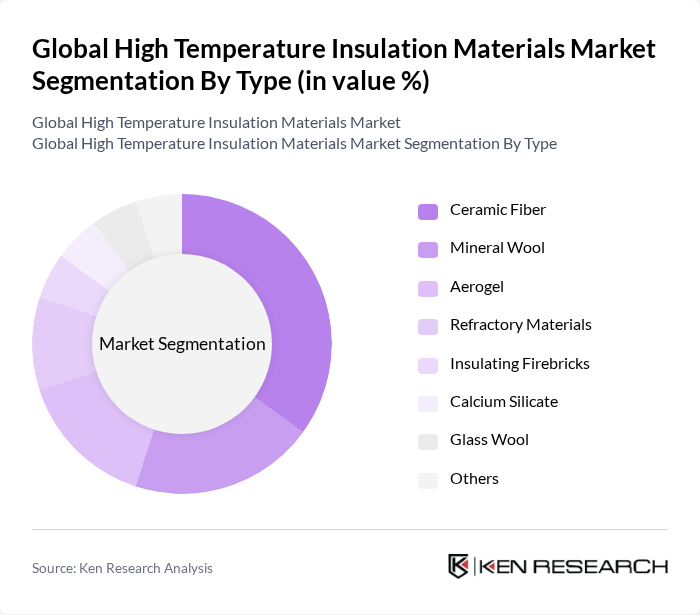

By Type:The high-temperature insulation materials market is segmented into ceramic fiber, mineral wool, aerogel, refractory materials, insulating firebricks, calcium silicate, glass wool, and others. Ceramic fiber remains the leading subsegment due to its superior thermal resistance, lightweight structure, and suitability for extreme temperature applications. Its widespread use in petrochemical, power generation, and metal processing industries is driven by its ability to maintain insulation performance under severe thermal stress, thereby supporting energy efficiency and operational reliability.

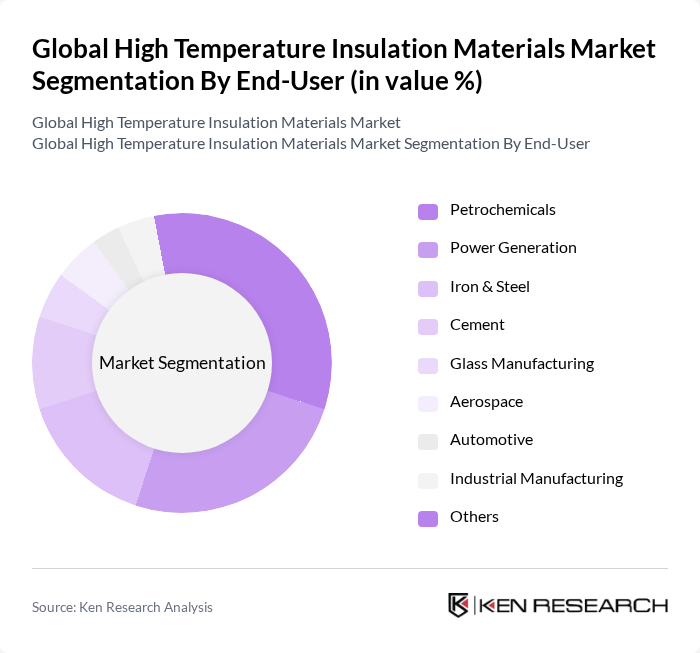

By End-User:The market is segmented by end-user industries, including petrochemicals, power generation, iron & steel, cement, glass manufacturing, aerospace, automotive, industrial manufacturing, and others. The petrochemical sector is the largest end-user, driven by the need for reliable high-temperature insulation to optimize energy use and reduce operational costs in refining and chemical processing. The growing emphasis on sustainability, regulatory compliance, and energy conservation in this sector continues to boost demand for advanced insulation materials.

Global High Temperature Insulation Materials Market Competitive Landscape

The Global High Temperature Insulation Materials Market is characterized by a dynamic mix of regional and international players. Leading participants such as Morgan Advanced Materials (Thermal Ceramics), Unifrax, 3M Company, RHI Magnesita, Johns Manville, Saint-Gobain, Knauf Insulation, Isolite Insulating Products Co., Ltd., Pyrotek, Etex Group (Promat), A.P. Green Industries, HarbisonWalker International, Trelleborg AB, Almatis GmbH, ZIRCAR Ceramics, Inc. contribute to innovation, geographic expansion, and service delivery in this space.

Global High Temperature Insulation Materials Market Industry Analysis

Growth Drivers

- Increasing Demand from the Aerospace Industry:The aerospace sector is projected to require approximately 1,500 tons of high-temperature insulation materials in future, driven by the need for lightweight and efficient thermal management solutions. With global air traffic expected to increase by approximately 4% annually in future, the demand for advanced insulation materials is set to rise significantly. This growth is further supported by the anticipated investment of $2.7 trillion in new aircraft in future, emphasizing the critical role of insulation in enhancing performance and safety.

- Rising Energy Efficiency Regulations:Governments worldwide are implementing stringent energy efficiency regulations, with the International Energy Agency (IEA) estimating that energy efficiency improvements could reduce global energy demand by approximately 12% in future. This regulatory push is driving industries to adopt high-temperature insulation materials that meet these standards. For instance, the U.S. Department of Energy has set a target to improve energy efficiency in industrial processes by 20% in future, further propelling the demand for advanced insulation solutions.

- Growth in Industrial Applications:The industrial sector is expected to consume over 2,000 tons of high-temperature insulation materials in future, fueled by the expansion of manufacturing and processing industries. Key sectors such as petrochemicals and power generation are increasingly adopting these materials to enhance operational efficiency and reduce energy losses. The global industrial output is projected to grow by approximately 3% in future, creating a robust demand for effective thermal insulation solutions that can withstand extreme conditions.

Market Challenges

- High Manufacturing Costs:The production of high-temperature insulation materials involves significant costs, with estimates indicating that manufacturing expenses can reach up to $15,000 per ton. This high cost is primarily due to the specialized raw materials and advanced technologies required for production. As industries seek to optimize budgets, the high upfront investment in insulation materials can deter adoption, particularly among smaller enterprises that may lack the financial resources to invest in such technologies.

- Limited Availability of Raw Materials:The supply chain for high-temperature insulation materials is constrained by the limited availability of key raw materials, such as alumina and silica. In future, the global supply of these materials is expected to fall short by approximately 10%, leading to potential production delays and increased costs. This scarcity is exacerbated by geopolitical tensions and trade restrictions, which can disrupt sourcing and impact the overall market dynamics for insulation materials.

Global High Temperature Insulation Materials Market Future Outlook

The future of the high-temperature insulation materials market appears promising, driven by technological advancements and a growing emphasis on sustainability. As industries increasingly prioritize energy efficiency and environmental responsibility, the demand for innovative insulation solutions is expected to rise. Furthermore, the integration of smart technologies into insulation products will enhance performance and monitoring capabilities, aligning with the broader trend of digital transformation across sectors. This evolution will likely create new avenues for growth and investment in the coming years.

Market Opportunities

- Expansion in Emerging Markets:Emerging markets, particularly in Asia-Pacific, are projected to see a surge in demand for high-temperature insulation materials, with an estimated growth rate of approximately 6% annually in future. This growth is driven by rapid industrialization and infrastructure development, creating significant opportunities for manufacturers to establish a foothold in these regions and cater to the increasing needs of various industries.

- Development of Bio-Based Insulation Materials:The shift towards sustainable materials presents a unique opportunity for the development of bio-based insulation solutions. With the global market for bio-based products expected to reach approximately $500 billion in future, companies investing in eco-friendly insulation technologies can capitalize on this trend. This innovation not only meets regulatory demands but also appeals to environmentally conscious consumers, enhancing market competitiveness.