India Aluminum Market Outlook to 2030

Region:Asia

Author(s):Yogita Sahu

Product Code:KROD4776

October 2024

91

About the Report

India Aluminum Market Overview

- The India Aluminum Market was valued at USD 11.28 billion, has seen growth driven by the increasing demand from key sectors such as transportation, construction, and packaging. The expansion of the automotive industry and the growing adoption of lightweight materials have contributed to this surge in demand.

- Major regions such as Maharashtra, Gujarat, and Odisha dominate the market due to their established industrial bases and proximity to raw material sources like bauxite. Maharashtra, with its strong manufacturing and automotive industries, leads in aluminum consumption, while Gujarat's robust ports and refineries facilitate aluminum exports.

- The Government of India is formulating a new National Aluminum Policy aimed at enhancing domestic production capacities and reducing import dependency. The policy includes incentives for domestic mining operations, expected to boost the output of bauxite and alumina by 10 million tons by 2025. It also focuses on increasing the competitiveness of Indian aluminum in the global market through duty reductions and export incentives.

India Aluminum Market Segmentation

By Product Type: The market is segmented by product type into primary aluminum, secondary/recycled aluminum, aluminum alloys, rolled aluminum products, and extruded aluminum products. Primary aluminum, produced directly from bauxite ore, has a dominant market share due to its essential role in industrial applications such as automotive and aerospace. Primary aluminums purity and strength make it indispensable in high-performance applications where reliability and structural integrity are crucial.

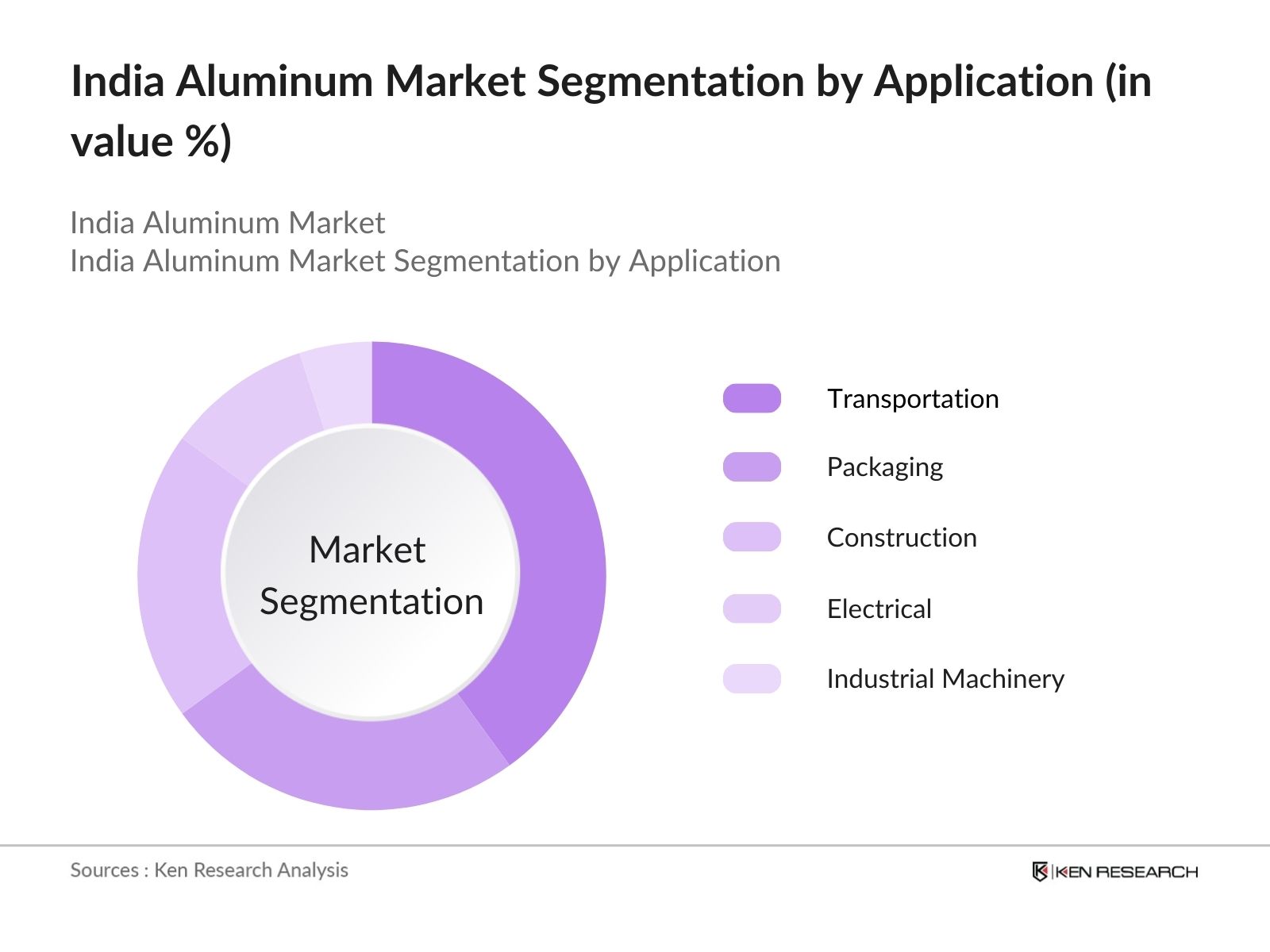

By Application: The market is also segmented by application into transportation, packaging, construction, electrical, and industrial machinery. The transportation segment holds the largest market share, driven by the increasing demand for lightweight vehicles, including electric vehicles (EVs) that rely heavily on aluminum for battery casings and other components. Additionally, aluminum's strength-to-weight ratio makes it an ideal material for aerospace and railways, contributing to its dominance in the transportation sector.

India Aluminum Market Competitive Landscape

The market is characterized by the presence of a few key players, both domestic and international. Companies such as Hindalco Industries, Vedanta Ltd., and National Aluminium Company (NALCO) dominate the market due to their large production capacities and extensive distribution networks. These players are strategically located near bauxite reserves, ensuring a stable raw material supply.

|

Company Name |

Establishment Year |

Headquarters |

Production Capacity |

Market Share |

Raw Material Sources |

Technological Capabilities |

Global Presence |

Sustainability Initiatives |

Key Clients |

|

Hindalco Industries |

1958 |

Mumbai, India |

|||||||

|

Vedanta Ltd. |

1976 |

Mumbai, India |

|||||||

|

National Aluminium (NALCO) |

1981 |

Bhubaneswar, India |

|||||||

|

Alcoa Corporation |

1888 |

Pittsburgh, USA |

|||||||

|

Rio Tinto |

1873 |

London, UK |

India Aluminum Market Analysis

Market Growth Drivers

- Increased Domestic Production of Aluminum: India is expected to produce over 3.6 million metric tons of aluminum in 2024, driven by expansions in domestic refining capacity. Key players such as Vedanta and Hindalco are adding new capacities to meet rising demand from industries like construction, automotive, and electricals, which are the primary consumers of aluminum. According to data from the Ministry of Mines, domestic production is projected to grow by 2025, supported by a strong focus on self-reliance (Aatmanirbhar Bharat) in aluminum production.

- Surge in Automotive and Electric Vehicle Manufacturing: The demand for aluminum in Indias automotive sector is rising rapidly, particularly in electric vehicles (EVs). Aluminum is a preferred material due to its lightweight and energy efficiency. In 2024, the Indian automotive industry is expected to consume nearly 1.2 million tons of aluminum, with a growing focus on reducing the weight of vehicles to enhance fuel efficiency.

- Growing Demand from Infrastructure and Power Transmission Projects: The Indian governments increased infrastructure spending, with an allocation of 10 trillion in the 2024 budget for highways, smart cities, and railways, will significantly boost aluminum consumption. Aluminum is a key material in power transmission lines, and the expansion of the Indian power gridan estimated 15,000 kilometers of transmission lines expected to be laid by 2025will require substantial aluminum for cables and structures.

Market Challenges

- High Energy Costs Impacting Production: Aluminum smelting is highly energy-intensive, with energy costs accounting for up to 40% of total production expenses. In 2024, the average cost of electricity for aluminum producers in India is reported at 6.5 per kilowatt-hour, significantly higher than other global competitors like China. This has led to cost pressures on domestic producers, who face difficulty competing on price in the global market, affecting profitability.

- Supply Chain Disruptions and Logistics Bottlenecks: Transportation costs in India, which average 2.5 per ton-kilometer for heavy commodities like aluminum, continue to be a major concern, especially with port congestion and rail inefficiencies. In 2024, it is estimated that supply chain disruptionsdue to infrastructure gapscould lead to delays of up to 15 days for export shipments, reducing Indias competitiveness in global aluminum exports.

India Aluminum Market Future Outlook

The India Aluminum industry is expected to witness robust growth over the next few years, driven by multiple factors. Increasing investment in infrastructure projects, such as the development of smart cities and expansion of public transportation systems, will significantly boost the demand for aluminum in the construction and transportation sectors.

Future Market Opportunities

- Increase in Domestic Aluminum Production Capacity: Over the next five years, India's aluminum production capacity is expected to grow by an additional 2 million metric tons, driven by investments from major players like Vedanta, Hindalco, and NALCO. These expansions are aligned with the governments goal of achieving self-reliance in aluminum production by 2028. This capacity growth will position India as one of the top aluminum producers globally.

- Rising Demand from Renewable Energy and Electric Vehicles: By 2028, Indias renewable energy sector will consume an additional 800,000 metric tons of aluminum annually, driven by the expansion of solar power projects and wind farms. The growing EV market, expected to produce over 4 million units by 2028, will also push demand for lightweight aluminum materials in battery casings, body frames, and electrical systems, as EVs become more prevalent.

Scope of the Report

|

Product Type |

Primary Aluminum |

|

Secondary/Recycled Aluminum |

|

|

Aluminum Alloys |

|

|

Rolled Aluminum Products (Sheets, Plates) |

|

|

Extruded Aluminum Products (Bars, Rods) |

|

|

Application |

Transportation (Automotive, Aerospace) |

|

Packaging (Cans, Foils) |

|

|

Construction (Building Materials) |

|

|

Electrical (Transmission Lines) |

|

|

Industrial Machinery |

|

|

End-User Industry |

Automotive |

|

Aerospace |

|

|

Building and Construction |

|

|

Packaging and Consumer Goods |

|

|

Electrical and Electronics |

|

|

Process Type |

Smelting |

|

Casting |

|

|

Rolling |

|

|

Extrusion |

|

|

Recycling |

|

|

Region |

North India |

|

South India |

|

|

West India |

|

|

East India |

Products

Key Target Audience Organizations and Entities Who Can Benefit by Subscribing This Report:

Investments and Venture Capital Firms

Aluminum Producers

Automotive Manufacturers

Government and Regulatory Bodies (Ministry of Mines, Ministry of Steel, Pollution Control Board)

Construction Companies

Electric Vehicle Manufacturers

Renewable Energy Companies

Packaging Industry Players

Companies

Players Mentioned in the Report:

Hindalco Industries

Vedanta Ltd.

National Aluminium Company (NALCO)

Jindal Aluminium Ltd.

Bharat Aluminium Company (BALCO)

Alcoa Corporation

Rio Tinto

Emirates Global Aluminium (EGA)

China Hongqiao Group

Norsk Hydro ASA

RUSAL

Aluminium Bahrain (Alba)

Century Aluminum Co.

Kaiser Aluminum

China Zhongwang Holdings

Table of Contents

1. India Aluminum Market Overview

1.1. Definition and Scope

1.2. Market Taxonomy

1.3. Market Growth Rate (Production Volumes, Exports, Imports, Domestic Consumption)

1.4. Market Segmentation Overview

2. India Aluminum Market Size (In USD Bn)

2.1. Historical Market Size (Production Capacity, Revenue, Trade Volumes)

2.2. Year-On-Year Growth Analysis (Domestic Demand, Price Trends, Raw Material Supply Chain)

2.3. Key Market Developments and Milestones (New Production Facilities, Smelting and Refining Capacity Enhancements, Export Agreements)

3. India Aluminum Market Analysis

3.1. Growth Drivers

3.1.1. Government Infrastructure Initiatives (Make in India, Smart Cities)

3.1.2. Expansion in Aerospace and Automotive Industries (Lightweight Materials Adoption)

3.1.3. Rise in Renewable Energy Installations (Solar and Wind Energy Equipment)

3.1.4. Growth in Packaging and Consumer Durables (Aluminum Cans, Foils)

3.2. Market Challenges

3.2.1. Volatility in Raw Material Prices (Bauxite and Alumina)

3.2.2. Environmental Regulations (Carbon Emissions Control, Waste Management)

3.2.3. High Energy Consumption in Production (Electricity Prices, Smelting Processes)

3.2.4. Competition from Global Producers (China, Middle East Exporters)

3.3. Opportunities

3.3.1. Growth in Recycling Capabilities (Circular Economy, Scrap Metal Usage)

3.3.2. Expansion in Electric Vehicles (EV Battery Enclosures, Lightweighting)

3.3.3. Increased Use of Aluminum in Construction (Skyscrapers, Bridges, Green Buildings)

3.3.4. Technological Advancements in Smelting and Casting (Energy Efficiency, Low Carbon Production)

3.4. Trends

3.4.1. Adoption of Low Carbon Aluminum (Decarbonization, EPD Certifications)

3.4.2. Digitalization in Production Processes (AI, IoT in Smelting and Casting)

3.4.3. Shifts in Global Trade Dynamics (Tariffs, Bilateral Agreements)

3.4.4. Expansion in Secondary Aluminum Market (Recycling Plants, Scrap Metal Export/Import)

3.5. Government Regulations

3.5.1. Import and Export Duties on Aluminum

3.5.2. Environmental Norms and Compliance (Air and Water Pollution Control)

3.5.3. Tax Incentives for Green Production Technologies

3.5.4. Public-Private Partnerships in Infrastructure Projects (Aluminum Usage in Railways, Roads)

3.6. SWOT Analysis

3.7. Stakeholder Ecosystem (Aluminum Producers, Government Entities, Raw Material Suppliers)

3.8. Porters Five Forces

3.9. Competition Ecosystem

4. India Aluminum Market Segmentation

4.1. By Product Type (In Value %)

4.1.1. Primary Aluminum

4.1.2. Secondary/Recycled Aluminum

4.1.3. Aluminum Alloys

4.1.4. Rolled Aluminum Products (Sheets, Plates, Foils)

4.1.5. Extruded Aluminum Products (Bars, Rods, Tubes)

4.2. By Application (In Value %)

4.2.1. Transportation (Automotive, Aerospace, Railways)

4.2.2. Packaging (Cans, Foils, Wrappers)

4.2.3. Construction (Building Materials, Windows, Doors)

4.2.4. Electrical (Transmission Lines, Conductors)

4.2.5. Industrial Machinery and Equipment

4.3. By End-User Industry (In Value %)

4.3.1. Automotive

4.3.2. Aerospace

4.3.3. Building and Construction

4.3.4. Packaging and Consumer Goods

4.3.5. Electrical and Electronics

4.4. By Process Type (In Value %)

4.4.1. Smelting

4.4.2. Casting

4.4.3. Rolling

4.4.4. Extrusion

4.4.5. Recycling

4.5. By Region (In Value %)

4.5.1. North India

4.5.2. South India

4.5.3. West India

4.5.4. East India

5. India Aluminum Market Competitive Analysis

5.1. Detailed Profiles of Major Companies

5.1.1. Vedanta Ltd.

5.1.2. National Aluminium Company (NALCO)

5.1.3. Hindalco Industries Ltd.

5.1.4. Bharat Aluminium Company (BALCO)

5.1.5. Jindal Aluminium Ltd.

5.1.6. Century Aluminum Co.

5.1.7. Rio Tinto

5.1.8. Alcoa Corporation

5.1.9. Emirates Global Aluminium (EGA)

5.1.10. Norsk Hydro ASA

5.1.11. RUSAL

5.1.12. Aluminium Bahrain (Alba)

5.1.13. China Hongqiao Group

5.1.14. China Zhongwang Holdings

5.1.15. Kaiser Aluminum

5.2. Cross Comparison Parameters

5.3. Market Share Analysis

5.4. Strategic Initiatives

5.5. Mergers and Acquisitions

5.6. Investment Analysis

5.7. Venture Capital Funding

5.8. Government Grants

5.9. Private Equity Investments

6. India Aluminum Market Regulatory Framework

6.1. Industry Standards

6.2. Compliance Requirements

6.3. Certification Processes

7. India Aluminum Future Market Size (In USD Bn)

7.1. Future Market Size Projections

7.2. Key Factors Driving Future Market

8. India Aluminum Future Market Segmentation

8.1. By Product Type (In Value %)

8.2. By Application (In Value %)

8.3. By Process Type (In Value %)

8.4. By End-User Industry (In Value %)

8.5. By Region (In Value %)

9. India Aluminum Market Analysts Recommendations

9.1. TAM/SAM/SOM Analysis

9.2. Customer Cohort Analysis

9.3. Marketing Initiatives

9.4. White Space Opportunity Analysis

Research Methodology

Step 1: Identification of Key Variables

The first phase involved mapping all major stakeholders in the India Aluminum Market. Secondary data sources, including proprietary databases, government publications, and industry reports, were utilized to define key market variables such as production volumes, capacity, and end-user segments.

Step 2: Market Analysis and Construction

Historical data on aluminum consumption, production, and trade were gathered from credible sources like government records and industry associations. The ratio of primary to recycled aluminum, along with the key application segments, was analyzed to construct market models and estimate future trends.

Step 3: Hypothesis Validation and Expert Consultation

Market assumptions were validated through consultations with industry experts, including executives from leading aluminum manufacturers. These interviews provided insights into market drivers, challenges, and the competitive landscape.

Step 4: Research Synthesis and Final Output

The final output was prepared after cross-verifying primary and secondary data sources. The research synthesis involved detailed segmentation analysis, competitive benchmarking, and the construction of a comprehensive future market outlook, ensuring a robust and accurate report.

Frequently Asked Questions

01. How big is the India Aluminum Market?

The India Aluminum Market is valued at USD 11.28 billion, driven by strong demand from the construction, automotive, and packaging sectors. Key factors include the rising use of lightweight materials in transportation and infrastructure development.

02. What are the challenges in the India Aluminum Market?

Challenges in the India Aluminum Market include the volatility in raw material prices, environmental regulations on production processes, and the high energy consumption in aluminum smelting. The market also faces competition from global producers like China and the Middle East.

03. Who are the major players in the India Aluminum Market?

The major players in the India Aluminum Market include Hindalco Industries, Vedanta Ltd., National Aluminium Company (NALCO), and global giants like Alcoa and Rio Tinto. These companies dominate due to their extensive production capacities and established distribution networks.

04. What are the growth drivers of the India Aluminum Market?

Key growth drivers in the India Aluminum Market include the increasing adoption of aluminum in electric vehicles, renewable energy installations, and government initiatives promoting infrastructure development. The rise in recycling initiatives also supports the market's growth.

05. What is the future outlook for the India Aluminum Market?

The India Aluminum Market is expected to experience significant growth driven by the expansion of the electric vehicle segment, increased government investment in infrastructure, and advancements in aluminum recycling technologies.

Why Buy From Us?

What makes us stand out is that our consultants follows Robust, Refine and Result (RRR) methodology. i.e. Robust for clear definitions, approaches and sanity checking, Refine for differentiating respondents facts and opinions and Result for presenting data with story

We have set a benchmark in the industry by offering our clients with syndicated and customized market research reports featuring coverage of entire market as well as meticulous research and analyst insights.

While we don't replace traditional research, we flip the method upside down. Our dual approach of Top Bottom & Bottom Top ensures quality deliverable by not just verifying company fundamentals but also looking at the sector and macroeconomic factors.

With one step in the future, our research team constantly tries to show you the bigger picture. We help with some of the tough questions you may encounter along the way: How is the industry positioned? Best marketing channel? KPI's of competitors? By aligning every element, we help maximize success.

Our report gives you instant access to the answers and sources that other companies might choose to hide. We elaborate each steps of research methodology we have used and showcase you the sample size to earn your trust.

If you need any support, we are here! We pride ourselves on universe strength, data quality, and quick, friendly, and professional service.