India Engineering Plastic Market Outlook to 2030

Region:Asia

Author(s):Naman Rohilla

Product Code:KROD3683

November 2024

95

About the Report

India Engineering Plastic Market Overview

- The India engineering plastic market is valued at USD 4 billion, based on a five-year historical analysis. The demand is primarily driven by the automotive sector's shift towards lightweight materials to enhance fuel efficiency and the growing electrical and electronics industry. The construction sector also plays a major role due to the use of engineering plastics in various applications such as piping systems and insulation materials. Increasing consumer preference for durable, high-performance plastics has further propelled market growth, making engineering plastics a versatile choice across multiple industries.

- Cities like Mumbai, Pune, and Chennai dominate the Indian engineering plastics market. These regions have strong automotive and manufacturing bases, with numerous Original Equipment Manufacturers (OEMs) and ancillary industries that rely on engineering plastics for high-performance applications. Chennai, being the Detroit of Asia, plays a crucial role in automotive production, leading to high demand for materials such as polyamides and polycarbonates in vehicle components. Additionally, these cities host many electronics manufacturers, driving the demand for engineering plastics in consumer and industrial electronics.

- India's Plastics Waste Management Rules, first introduced in 2016 and updated in 2022, aim to reduce the environmental impact of plastic waste. Under these rules, manufacturers are required to ensure the recycling and disposal of plastic products through extended producer responsibility (EPR). In 2023, the Ministry of Environment reported that 60% of India's plastic waste was being managed under these regulations, with increased penalties for non-compliance driving improvements in the sector.

India Engineering Plastics Market Segmentation

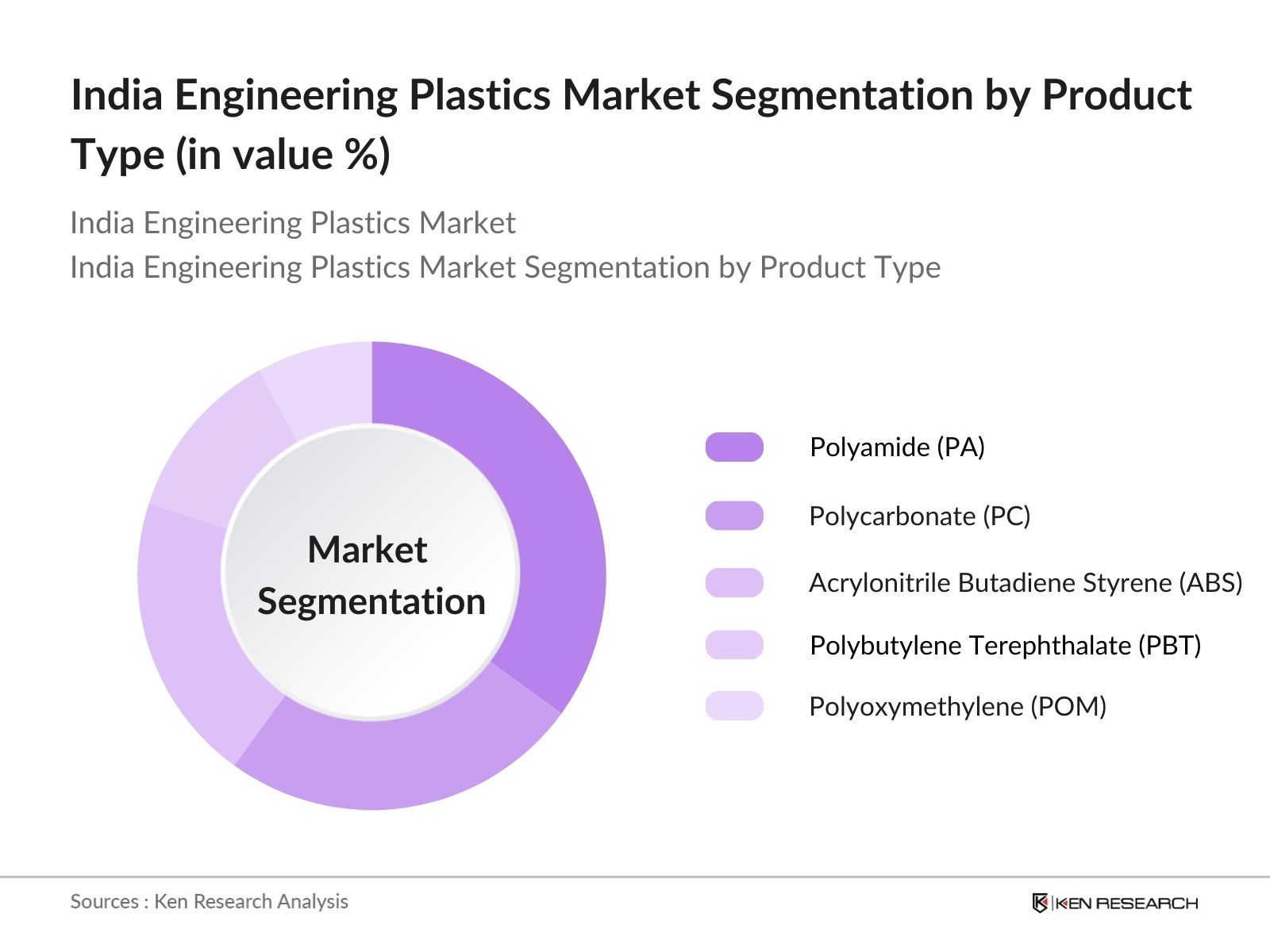

- By Product Type: India's engineering plastics market is segmented by product type into polyamide (PA), polycarbonate (PC), acrylonitrile butadiene styrene (ABS), polybutylene terephthalate (PBT), and polyoxymethylene (POM). Polyamide (PA) holds a dominant market share, driven by its extensive use in automotive parts, including gears, bushings, and under-the-hood components. Its high strength, excellent wear resistance, and ability to withstand high temperatures make it the go-to choice in critical engineering applications, particularly for automotive manufacturers seeking to reduce vehicle weight while maintaining performance.

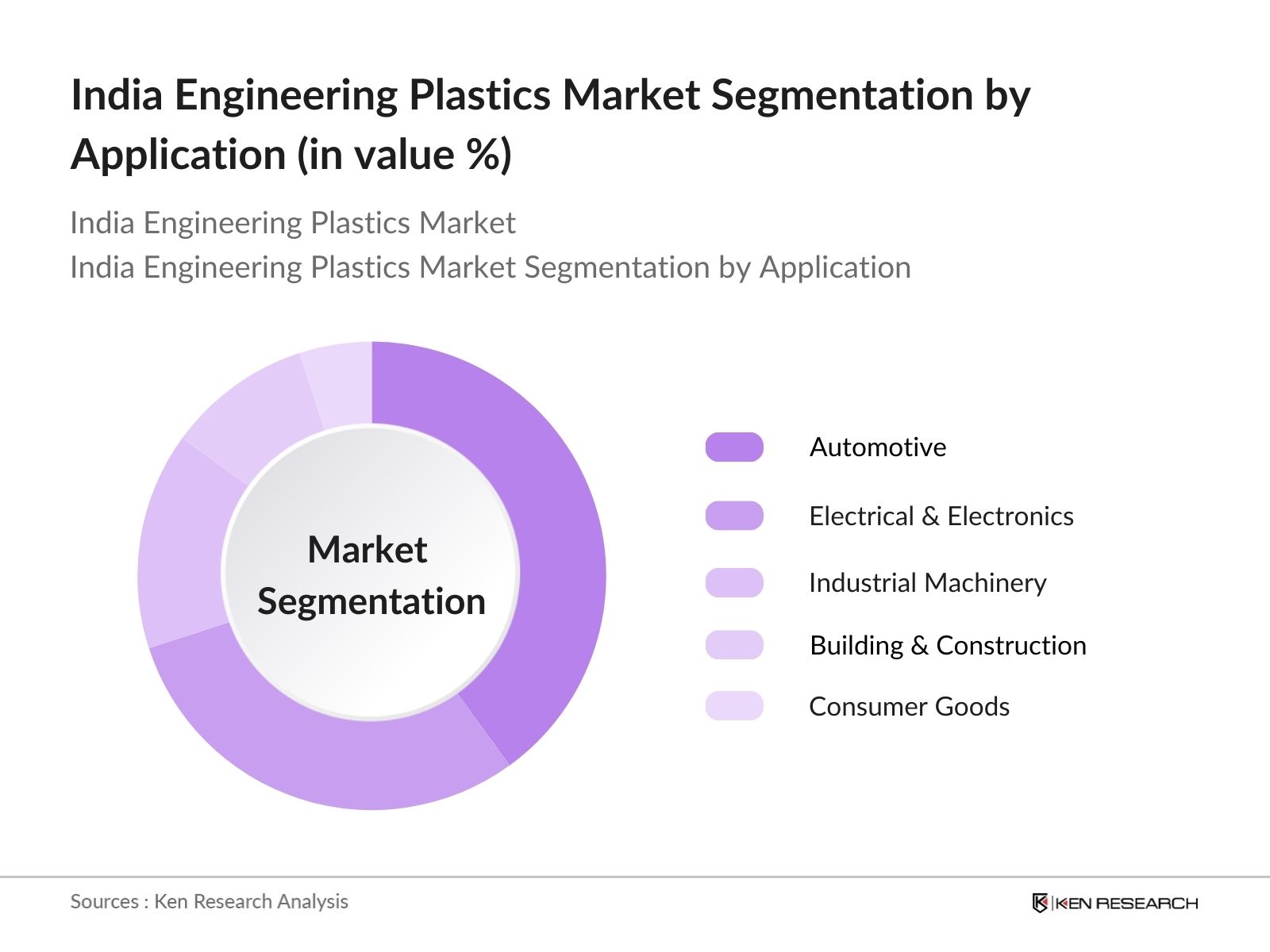

- By Application: India's engineering plastics market is further segmented by application into automotive, electrical & electronics, industrial machinery, building & construction, and consumer goods. The automotive sector dominates the market share, attributed to the growing shift towards lightweight materials to improve fuel efficiency and reduce emissions. Engineering plastics are widely used in under-the-hood applications, fuel systems, and interior components. As automakers push towards electric vehicles (EVs), the demand for high-performance plastics to reduce vehicle weight and enhance thermal stability is rising, further boosting the market for engineering plastics in this segment.

India Engineering Plastics Market Competitive Landscape

The India engineering plastics market is dominated by a mix of multinational corporations and domestic companies. Companies like BASF and SABIC have manufacturing capabilities in India and strong distribution networks, contributing to their dominance. This consolidation among key players highlights the influence of these companies on pricing, product innovations, and market dynamics.

|

Company |

Establishment Year |

Headquarters |

Revenue |

Global Presence |

Product Portfolio |

R&D Investments |

Manufacturing Units |

Sustainability Initiatives |

|

BASF SE |

1865 |

Ludwigshafen, Germany |

- |

- |

- |

- |

- |

- |

|

SABIC |

1976 |

Riyadh, Saudi Arabia |

- |

- |

- |

- |

- |

- |

|

Covestro AG |

2015 |

Leverkusen, Germany |

- |

- |

- |

- |

- |

- |

|

DuPont |

1802 |

Wilmington, USA |

- |

- |

- |

- |

- |

- |

|

Celanese Corporation |

1918 |

Dallas, USA |

- |

- |

- |

- |

- |

- |

India Engineering Plastics Market Analysis

India Engineering Plastics Market Growth Drivers

- Increasing Adoption in Automotive Sector: The automotive sector in India has seen a growing demand for engineering plastics, driven by the need for lightweight materials that reduce vehicle weight and increase fuel efficiency. In 2023, India produced 4.7 million vehicles, according to the Ministry of Heavy Industries. The use of engineering plastics is becoming crucial for electric vehicles (EVs) and hybrid cars, which benefit from the high strength-to-weight ratio of these materials. This shift is driven by government policies, such as the Faster Adoption and Manufacturing of Hybrid and Electric Vehicles (FAME) scheme, which supports the automotive industry's transformation towards lighter, more energy-efficient vehicles.

- Rise in Demand for Consumer Electronics: India's consumer electronics industry is experiencing rapid growth, with electronics production reaching INR 7.96 trillion in 2023, as per the Ministry of Electronics and Information Technology. Engineering plastics are integral to this sector, given their use in manufacturing lightweight and durable components for smartphones, laptops, and home appliances. The surge in demand for smartphones and wearable devices, driven by a tech-savvy young population, has led to an increase in the need for plastics like ABS and polycarbonate, which offer electrical insulation and thermal resistance properties.

- Expanding Construction Industry: Indias construction industry is expanding, with investments totalling INR 35.47 trillion in 2023, according to the Ministry of Housing and Urban Affairs. Engineering plastics are increasingly used in construction applications, such as pipes, insulation, and glazing, due to their durability and corrosion resistance. With the government's push for infrastructure development through projects like the Smart Cities Mission, engineering plastics are expected to play a key role in the building of energy-efficient and resilient structures.

India Engineering Plastics Market Challenges

- Fluctuating Raw Material Prices: The prices of raw materials used in engineering plastics, such as crude oil derivatives, have seen volatility due to geopolitical tensions and supply chain disruptions. For instance, the Indian Oil Corporation reported that the price of crude oil rose to USD 94 per barrel in 2023, affecting the cost of producing plastics like polypropylene and polyamide. These fluctuations make it challenging for manufacturers to manage costs and maintain profitability, especially in industries that operate on thin margins, such as automotive and consumer goods.

- Environmental and Regulatory Compliance: India's stringent environmental regulations on plastic production and disposal are challenging for the engineering plastics market. The Plastic Waste Management Rules, 2016, enforced by the Ministry of Environment, Forest and Climate Change, mandate extended producer responsibility (EPR) for plastic waste, increasing compliance costs for manufacturers. In 2022, fines amounting to INR 1.5 billion were levied on non-compliant companies, highlighting the pressure on the industry to adopt greener production practices.

India Engineering Plastics Market Future Outlook

The India engineering plastics market is poised for growth over the next five years, driven by rising demand in the automotive and electronics sectors. Continuous advancements in engineering polymers, such as the development of bio-based plastics, and increasing use in electric vehicles, will contribute to future growth. In addition, sustainability initiatives and the implementation of government policies promoting recycling and waste management will create new opportunities for players in the market.

India Engineering Plastics Market Opportunities

- R&D in Bio-based Engineering Plastics: India's focus on sustainability has driven research and development into bio-based engineering plastics, which are derived from renewable resources like corn starch and sugarcane. In 2023, the Department of Biotechnology reported an investment of INR 1.2 billion in R&D for bio-plastics, focusing on applications in packaging, agriculture, and automotive industries. These eco-friendly materials offer the same performance as traditional plastics, making them attractive for manufacturers seeking to meet environmental regulations.

- Growing Electric Vehicle (EV) Market: The electric vehicle (EV) market in India is set to expand, with the sale of EVs reaching 1.39 million units in 2023, as per the Ministry of Road Transport and Highways. Engineering plastics are vital in EV production, particularly for battery casings, electrical insulation, and lightweight body parts. The rise of EV adoption, driven by government incentives like the FAME II scheme and the production-linked incentive (PLI) scheme, offers growth opportunities for the engineering plastics market.

Scope of the Report

|

Product Type |

Polyamide (PA) Polycarbonate (PC) Acrylonitrile Butadiene Styrene (ABS) Polybutylene Terephthalate (PBT) Polyoxymethylene (POM) |

|

Application |

Automotive Electrical & Electronics Industrial Machinery Building & Construction Consumer Goods |

|

End User Industry |

Automotive OEMs Electronics Manufacturers Industrial Equipment Producers |

|

Region |

North India South India East India West India |

Products

Key Target Audience

Automotive OEMs

Electronics Manufacturers

Industrial Equipment Producers

Polymer Manufacturers

Plastic Molded Parts Suppliers

Investments and Venture Capitalist Firms

Government Bodies (Ministry of Heavy Industries, Ministry of Chemicals and Fertilizers)

Regulatory Bodies (Central Pollution Control Board, Bureau of Indian Standards)

Companies

Major Players in the India Engineering Plastics Market

BASF SE

SABIC

Covestro AG

DuPont

Celanese Corporation

Solvay

Lanxess AG

Mitsubishi Engineering-Plastics Corporation

Teijin Limited

LG Chem

Evonik Industries

DSM Engineering Plastics

RTP Company

Asahi Kasei Corporation

Arkema

Table of Contents

1. India Engineering Plastics Market Overview

1.1. Definition and Scope

1.2. Market Taxonomy

1.3. Key Market Growth Rate

1.4. Engineering Plastics Lifecycle Analysis

2. India Engineering Plastics Market Size (In USD Bn)

2.1. Historical Market Size (In USD)

2.2. Year-on-Year Growth Analysis

2.3. Milestones and Key Market Developments

3. India Engineering Plastics Market Analysis

3.1. Growth Drivers (Demand for Lightweight Materials in Automotive, Electronics)

3.1.1. Increasing Adoption in Automotive Sector

3.1.2. Rise in Demand for Consumer Electronics

3.1.3. Expanding Construction Industry

3.1.4. Focus on Sustainability and Circular Economy

3.2. Market Challenges (Cost Volatility, Environmental Concerns)

3.2.1. Fluctuating Raw Material Prices

3.2.2. Environmental and Regulatory Compliance

3.2.3. Technological Barriers in Recycling

3.3. Opportunities (Biodegradable Engineering Plastics, Growth in EVs)

3.3.1. R&D in Bio-based Engineering Plastics

3.3.2. Growing Electric Vehicle (EV) Market

3.3.3. Replacement of Metals with Plastics in Key Applications

3.4. Market Trends (Sustainability, Technological Integration)

3.4.1. Circular Economy Initiatives in Plastics

3.4.2. Technological Advancements in Polymer Blends

3.4.3. Increased Adoption of Recycled Engineering Plastics

3.5. Government Regulations (India's Plastics Waste Management)

3.5.1. National Plastics Waste Management Rules

3.5.2. Policies Supporting R&D in Sustainable Plastics

3.5.3. Initiatives for Plastics Recycling

3.6. SWOT Analysis

3.7. Value Chain Analysis (Raw Materials to End Product)

3.8. Porters Five Forces Analysis

3.9. Competitive Ecosystem

4. India Engineering Plastics Market Segmentation

4.1. By Product Type (In Value %)

4.1.1. Polyamide (PA)

4.1.2. Polycarbonate (PC)

4.1.3. Acrylonitrile Butadiene Styrene (ABS)

4.1.4. Polybutylene Terephthalate (PBT)

4.1.5. Polyoxymethylene (POM)

4.2. By Application (In Value %)

4.2.1. Automotive

4.2.2. Electrical & Electronics

4.2.3. Industrial Machinery

4.2.4. Building & Construction

4.2.5. Consumer Goods

4.3. By End User Industry (In Value %)

4.3.1. Automotive OEMs

4.3.2. Electronics Manufacturers

4.3.3. Industrial Equipment Producers

4.4. By Region (In Value %)

4.4.1. North India

4.4.2. South India

4.4.3. East India

4.4.4. West India

5. India Engineering Plastics Market Competitive Analysis

5.1. Detailed Profiles of Major Competitors

5.1.1. BASF SE

5.1.2. SABIC

5.1.3. Covestro AG

5.1.4. DuPont

5.1.5. Celanese Corporation

5.1.6. Solvay

5.1.7. Lanxess AG

5.1.8. Mitsubishi Engineering-Plastics Corporation

5.1.9. Teijin Limited

5.1.10. LG Chem

5.1.11. Evonik Industries

5.1.12. DSM Engineering Plastics

5.1.13. RTP Company

5.1.14. Asahi Kasei Corporation

5.1.15. Arkema

5.2. Cross Comparison Parameters (Revenue, Production Capacity, Inception Year, Number of Employees, Global Presence, R&D Investments, Key Patents, Product Innovation)

5.3. Market Share Analysis

5.4. Strategic Initiatives (Partnerships, Collaborations, Joint Ventures)

5.5. Mergers and Acquisitions

5.6. Investment Analysis

5.7. Venture Capital Funding

5.8. Government Grants and Incentives

5.9. Private Equity Investments

6. India Engineering Plastics Market Regulatory Framework

6.1. Industry Certifications and Compliance (ISO, REACH, RoHS)

6.2. Recycling Standards and Policies

6.3. Government Initiatives on Plastics Sustainability

7. India Engineering Plastics Future Market Size (In USD Bn)

7.1. Market Size Projections (In USD)

7.2. Factors Influencing Future Growth (EV Expansion, Recycling Trends, Bio-based Plastics)

8. India Engineering Plastics Future Market Segmentation

8.1. By Product Type (In Value %)

8.2. By Application (In Value %)

8.3. By End User Industry (In Value %)

8.4. By Region (In Value %)

9. India Engineering Plastics Market Analyst's Recommendations

9.1. TAM/SAM/SOM Analysis (Total Addressable Market, Serviceable Addressable Market, Serviceable Obtainable Market)

9.2. Customer Acquisition Strategy

9.3. Competitive Positioning and White Space Analysis

9.4. Innovation and R&D Opportunities

Research Methodology

Step 1: Identification of Key Variables

The initial stage involves creating an ecosystem map to understand the key stakeholders within the India Engineering Plastics Market. This requires detailed desk research using proprietary and secondary databases to extract relevant industry information. Critical variables influencing the market, such as production capacities, material demand, and industry regulations, are identified.

Step 2: Market Analysis and Construction

In this step, historical data pertaining to the Indian Engineering Plastics Market is gathered and analyzed. This includes evaluating market penetration rates, demand-supply dynamics, and performance metrics of various product segments. The goal is to derive accurate estimates and growth drivers through detailed market construction.

Step 3: Hypothesis Validation and Expert Consultation

Market hypotheses are validated through expert consultations using methods such as CATIs (computer-assisted telephone interviews) with key stakeholders in the market. These consultations provide valuable insights, enabling a clearer understanding of market trends, operational challenges, and competitive pressures.

Step 4: Research Synthesis and Final Output

Finally, interactions with plastic manufacturers and industry leaders are carried out to validate the findings. These discussions are essential for confirming statistical insights derived from the bottom-up approach and ensuring the final report is accurate and actionable.

Frequently Asked Questions

01. How big is the India Engineering Plastics Market?

The India engineering plastics market is valued at USD 4 billion, driven by growth in automotive and electronics sectors.

02. What are the challenges in the India Engineering Plastics Market?

India engineering plastics market challenges include fluctuating raw material prices, environmental concerns related to plastic waste, and stringent government regulations on plastic use.

03. Who are the major players in the India Engineering Plastics Market?

Key players in the India engineering plastics market include BASF SE, SABIC, Covestro AG, DuPont, and Celanese Corporation, which lead due to their extensive product portfolios and global distribution networks.

04. What are the growth drivers of the India Engineering Plastics Market?

India engineering plastics market growth is primarily driven by the rising demand in the automotive sector for lightweight materials, as well as advancements in electronics manufacturing, which increasingly rely on durable, heat-resistant plastics.

Why Buy From Us?

What makes us stand out is that our consultants follows Robust, Refine and Result (RRR) methodology. i.e. Robust for clear definitions, approaches and sanity checking, Refine for differentiating respondents facts and opinions and Result for presenting data with story

We have set a benchmark in the industry by offering our clients with syndicated and customized market research reports featuring coverage of entire market as well as meticulous research and analyst insights.

While we don't replace traditional research, we flip the method upside down. Our dual approach of Top Bottom & Bottom Top ensures quality deliverable by not just verifying company fundamentals but also looking at the sector and macroeconomic factors.

With one step in the future, our research team constantly tries to show you the bigger picture. We help with some of the tough questions you may encounter along the way: How is the industry positioned? Best marketing channel? KPI's of competitors? By aligning every element, we help maximize success.

Our report gives you instant access to the answers and sources that other companies might choose to hide. We elaborate each steps of research methodology we have used and showcase you the sample size to earn your trust.

If you need any support, we are here! We pride ourselves on universe strength, data quality, and quick, friendly, and professional service.