India Industrial Robot Market Outlook to 2030

Region:Asia

Author(s):Paribhasha Tiwari

Product Code:KROD8191

November 2024

95

About the Report

India Industrial Robot Market Overview

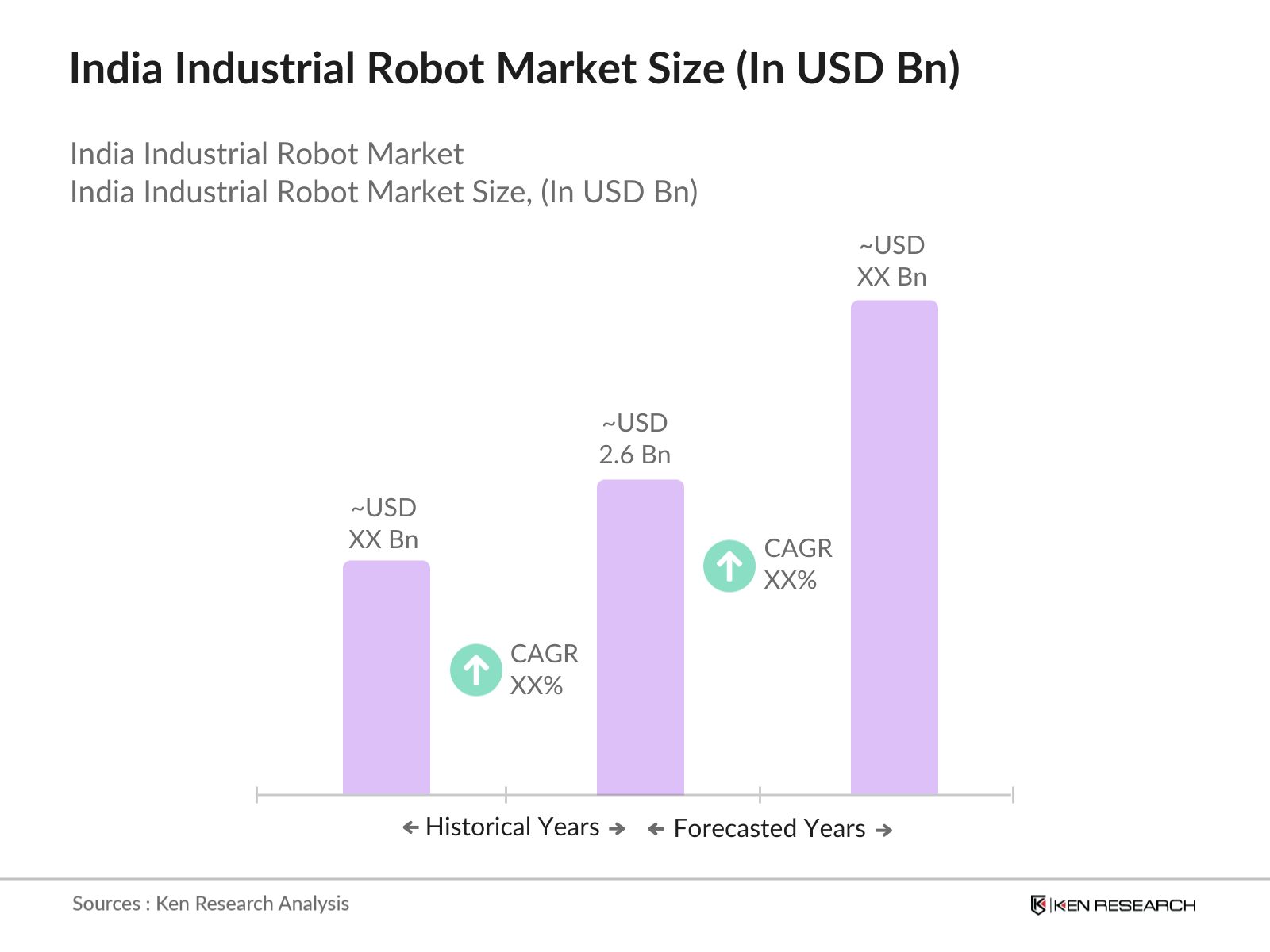

- The India Industrial Robot Market is valued at USD 2.6 billion, based on a five-year historical analysis. The growth of this market is driven by increasing automation across industries, particularly in automotive, electronics, and manufacturing sectors. As companies prioritize efficiency and precision, the adoption of robotics has surged, supported by government initiatives such as the "Make in India" campaign that encourages local manufacturing. The demand for improved operational efficiency and labor shortage concerns are further fueling the adoption of industrial robots.

- The dominance of cities like Bengaluru, Pune, and Chennai in the India industrial robot market is due to their status as major manufacturing hubs. These cities have established automotive, electronics, and heavy engineering industries, which have high demands for automation. Additionally, the presence of large industrial zones and favorable government policies supporting industrial growth have contributed to the strong positioning of these cities as leaders in the industrial robot market.

- To facilitate automation, the government offers tax exemptions and subsidies for companies investing in advanced manufacturing technologies. In 2024, the Indian government extended subsidies worth INR 4,500 crore to over 2,000 companies adopting robotic systems, thus easing the financial burden of automation and making it more accessible to industries across the country.

India Industrial Robot Market Segmentation

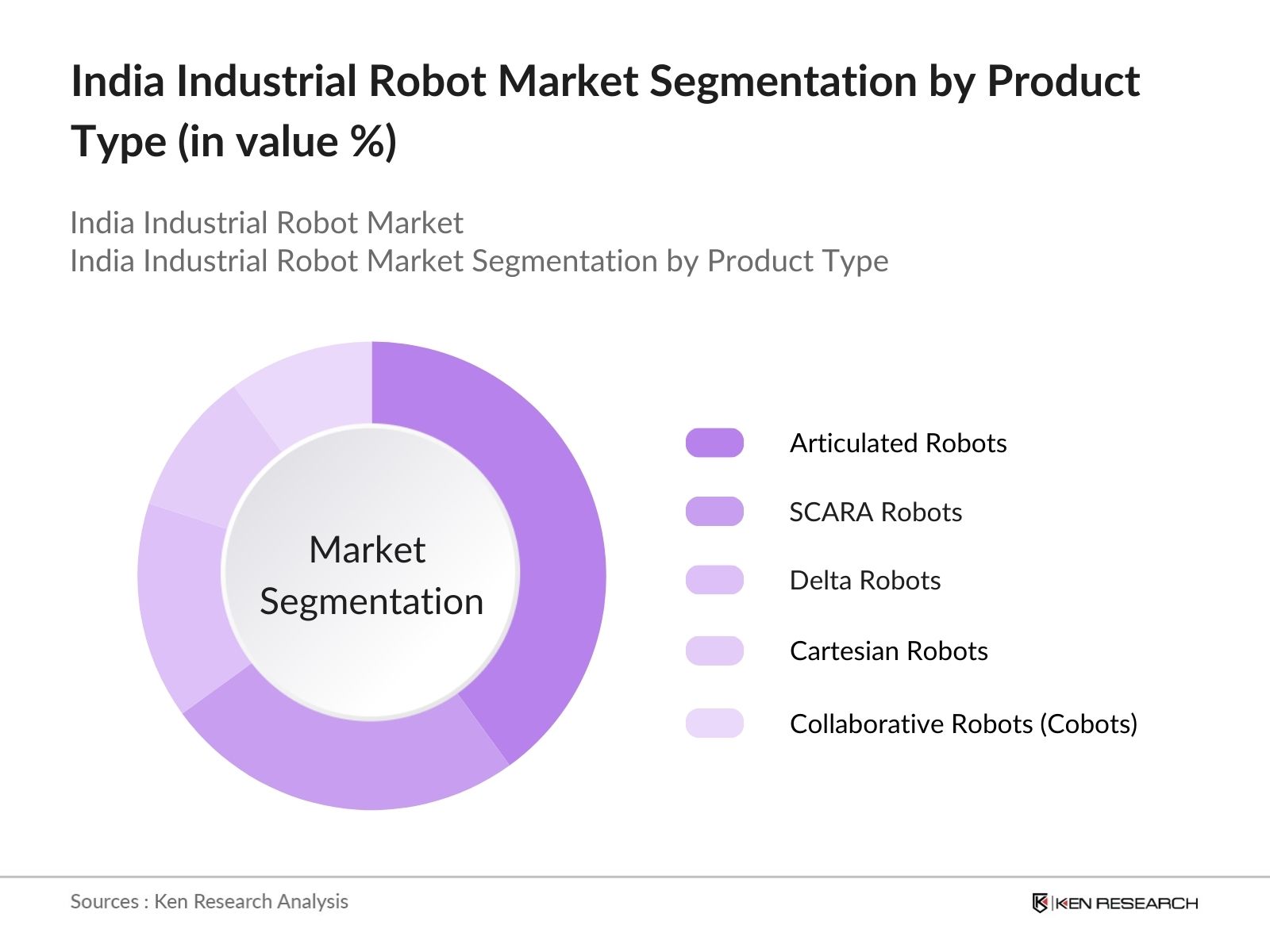

- By Product Type: The India Industrial Robot Market is segmented by product type into articulated robots, SCARA robots, delta robots, Cartesian robots, and collaborative robots (cobots). Among these, articulated robots dominate the market share due to their versatility and ability to perform complex tasks such as welding, painting, and material handling. These robots are widely used in the automotive and heavy machinery industries, where precision and flexibility are crucial for operations. The extensive use of articulated robots in these industries has led to their prominence in the Indian market.

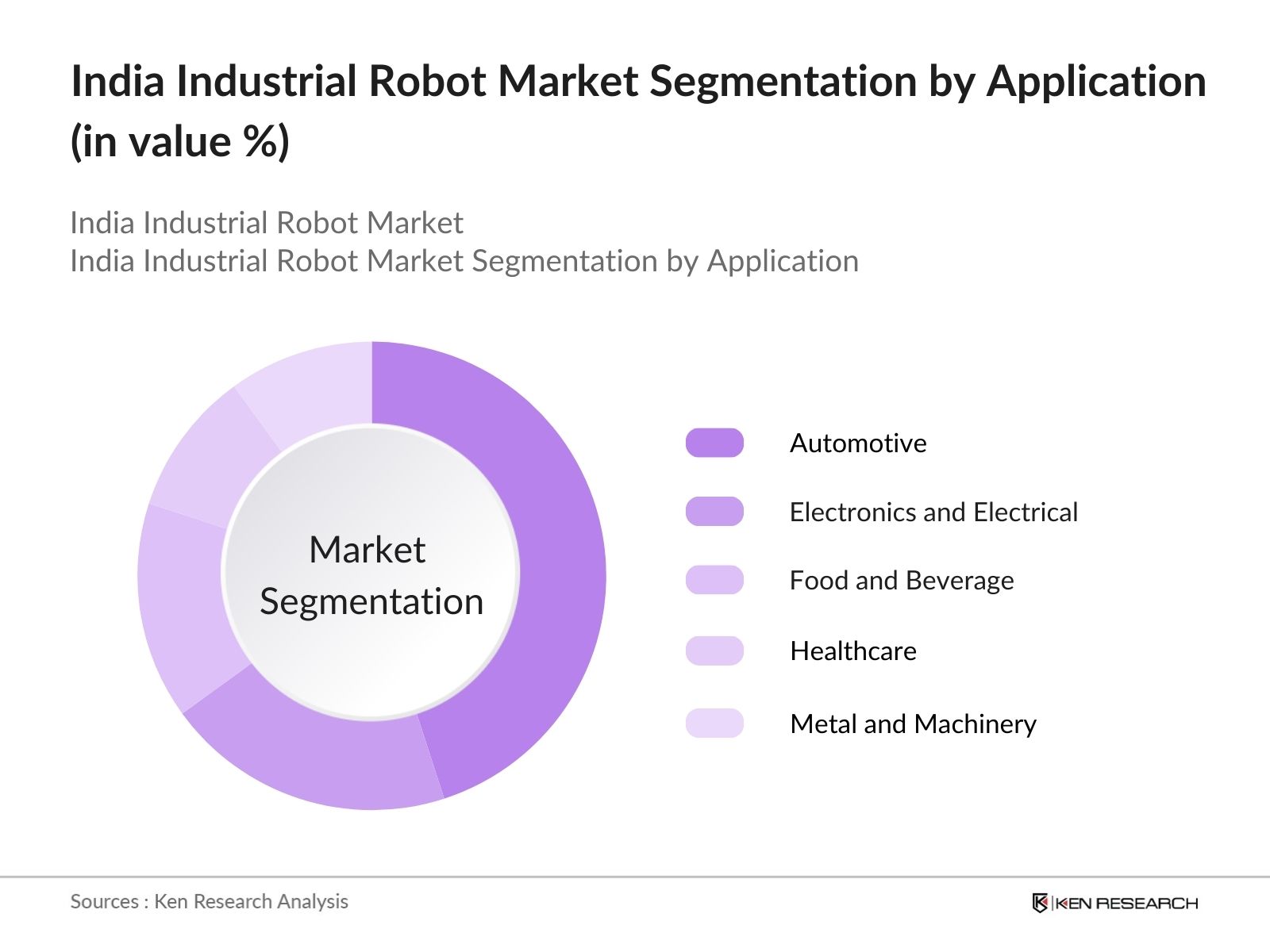

- By Application: The market is also segmented by application into the automotive industry, electronics and electrical, food and beverage, healthcare, and metal and machinery manufacturing. The automotive industry holds a dominant share in the market due to the increasing demand for automation in assembly lines, where precision and speed are critical. Industrial robots in the automotive sector assist in welding, material handling, and assembly, which are integral to enhancing productivity and reducing human error.

India Industrial Robot Market Competitive Landscape

The India Industrial Robot Market is dominated by global players, who have established strong local manufacturing capabilities and partnerships with Indian industries. The competitive landscape is characterized by major global manufacturers, alongside some local players.

|

Company |

Establishment Year |

Headquarters |

Employees |

Product Range |

Technological Capabilities |

R&D Investments |

Global Presence |

Recent Collaborations |

|

ABB Ltd. |

1883 |

Switzerland |

- | - | - | - | - | - |

|

Fanuc India Pvt. Ltd. |

1956 |

Japan |

- | - | - | - | - | - |

|

Yaskawa India Pvt. Ltd. |

1915 |

Japan |

- | - | - | - | - | - |

|

Kuka Robotics India Pvt. Ltd. |

1898 |

Germany |

- | - | - | - | - | - |

|

Mitsubishi Electric India Pvt. Ltd. |

1921 |

Japan |

- | - | - | - | - | - |

India Industrial Robot Market Analysis

Market Growth Drivers

- Increasing adoption of automation in manufacturing: India has seen a significant rise in automation in the manufacturing sector, driven by the need for improved operational efficiency. As of 2024, the Indian manufacturing industry employed over 2 million robots, focusing on industries like automotive, electronics, and heavy machinery. Automation helps reduce production time and improve accuracy, which is essential for scaling operations in highly competitive markets such as India. Government programs like the Production Linked Incentive (PLI) scheme also promote the adoption of automated technologies, further driving demand for industrial robots.

- Growing demand for precision and efficiency in industrial processes: Industrial processes in India are increasingly emphasizing the need for precision to minimize defects and improve productivity. Sectors like automotive manufacturing are deploying robots for tasks such as welding and material handling to achieve high levels of precision. In 2024, Indian automotive factories deployed over 500,000 robots to enhance productivity, cutting operational inefficiencies and reducing the error rate in production processes. This rise in demand for accurate, efficient manufacturing systems fuels the growth of industrial robots in India.

- Government support for digitalization and industrial modernization: The Indian governments focus on "Digital India" and "Make in India" initiatives has propelled investments in robotics and automation in various industries. By 2024, the government allocated $5 billion to modernize industrial sectors by promoting the use of robots in sectors like defense, aerospace, and pharmaceuticals. Government policies offer tax breaks and subsidies for industries adopting advanced manufacturing technologies, increasing the penetration of industrial robots in medium to large-scale industries.

Market Challenges

- High capital investment in advanced robotics systems: The adoption of industrial robots in India faces a challenge due to high upfront costs. In 2024, the cost of implementing a full-scale industrial robotic system for a medium-sized factory was estimated to be around INR 20-30 crore. This high capital investment is a significant barrier for smaller manufacturers in sectors like textiles and consumer goods, where profit margins are thin, making the adoption of advanced robotics a slow and costly process.

- Integration challenges with existing infrastructure: Indian manufacturing facilities, especially small and medium enterprises (SMEs), often have outdated infrastructure. Integrating advanced robots into legacy systems can be complicated and costly, requiring significant upgrades. In 2024, nearly 40% of SMEs reported difficulties in retrofitting existing equipment with robotic systems, slowing down the broader adoption of industrial robots. The need for seamless integration remains a key challenge in expanding robotic applications across diverse sectors.

India Industrial Robot Market Future Outlook

Over the next five years, the India Industrial Robot Market is expected to witness significant growth, driven by the rising demand for automation across industries and the government's push toward digitalization and smart manufacturing. The adoption of advanced robotics, including cobots and AI-integrated robots, is likely to expand beyond traditional industries like automotive and electronics, finding applications in sectors such as healthcare, logistics, and agriculture.

Market Opportunities

- Rising demand for industrial robots in small and medium enterprises (SMEs): SMEs in India are increasingly turning to automation to enhance competitiveness. The governments push for SME modernization, including financial incentives for automation, has accelerated this trend. In 2024, over 100,000 SMEs adopted industrial robots for assembly, welding, and packaging processes, driven by the need to improve output and reduce operational costs. The growing interest in automation among SMEs presents a massive growth opportunity for the industrial robot market.

- Growing adoption of collaborative robots in various sectors: Collaborative robots, or cobots, are becoming increasingly popular in India due to their affordability and versatility in applications such as assembly, quality inspection, and logistics. Cobots work alongside human workers, making them suitable for SMEs with limited space and resources. In 2024, approximately 30,000 cobots were deployed across industries, ranging from food processing to pharmaceuticals, demonstrating their growing role in the industrial landscape.

Scope of the Report

|

By Product Type |

Articulated Robot SCARA Robots Delta Robots Cartesian Robots Cobots |

|

By Application |

Automotive Electronics & Electrical Food & Beverage Healthcare Metal & Machinery |

|

By Technology |

Automated Welding Assembly Automation Pick & Place Material Handling Quality Inspection |

|

By End User |

Manufacturing Logistics Agriculture Healthcare, Aerospace |

|

By Region |

North East South West |

Products

Key Target Audience

Industrial Robot Manufacturers

Automotive Manufacturers

Electronics & Electrical Companies

Healthcare Equipment Manufacturers

Food & Beverage Manufacturers

Metal and Machinery Companies

Investors and Venture Capitalist Firms

Government and Regulatory Bodies (Ministry of Heavy Industries, Ministry of Electronics & IT)

Companies

Players Mentioned in the Report:

ABB Ltd.

Fanuc India Pvt. Ltd.

Yaskawa India Pvt. Ltd.

Kuka Robotics India Pvt. Ltd.

Mitsubishi Electric India Pvt. Ltd.

Panasonic India Pvt. Ltd.

Hyundai Robotics

Universal Robots

Omron Automation Pvt. Ltd.

Toshiba Machine Co. Ltd.

Table of Contents

1. India Industrial Robot Market Overview

1.1 Definition and Scope

1.2 Market Taxonomy

1.3 Market Growth Rate

1.4 Market Segmentation Overview

2. India Industrial Robot Market Size (In USD Mn)

2.1 Historical Market Size

2.2 Year-On-Year Growth Analysis

2.3 Key Market Developments and Milestones

3. India Industrial Robot Market Analysis

3.1 Growth Drivers (Automation, Cost Efficiency, Labor Shortage, and Industry 4.0)

3.1.1 Increasing adoption of automation in manufacturing

3.1.2 Growing demand for precision and efficiency in industrial processes

3.1.3 Government support for digitalization and industrial modernization

3.1.4 Emergence of Industry 4.0 and smart manufacturing systems

3.2 Market Challenges (High Initial Costs, Technological Complexity, and Supply Chain Issues)

3.2.1 High capital investment in advanced robotics systems

3.2.2 Integration challenges with existing infrastructure

3.2.3 Shortage of skilled labor for maintenance and operation

3.2.4 Global supply chain disruptions affecting component availability

3.3 Opportunities (Expansion in SMEs, Collaborative Robots, and R&D Initiatives)

3.3.1 Rising demand for industrial robots in small and medium enterprises (SMEs)

3.3.2 Growing adoption of collaborative robots in various sectors

3.3.3 Increased government and private sector R&D investments

3.3.4 Expansion of automation into new industries such as logistics and healthcare

3.4 Trends (AI Integration, Collaborative Robotics, and Robotics as a Service)

3.4.1 Integration of AI and machine learning for improved robot autonomy

3.4.2 Rise in use of collaborative robots (cobots) for human-robot interaction

3.4.3 Growth of "Robotics as a Service" (RaaS) models

3.4.4 Advances in sensors and vision systems enhancing robotic capabilities

3.5 Government Regulation (Make in India, PLI Schemes, and Industrial Automation Policies)

3.5.1 Governments "Make in India" initiative promoting local manufacturing

3.5.2 Production Linked Incentive (PLI) schemes for industrial modernization

3.5.3 Policies encouraging the development of AI and robotics ecosystems

3.5.4 Import duties and regulations on industrial robotic systems

3.6 SWOT Analysis (India Industrial Robot Market)

3.7 Stakeholder Ecosystem (Manufacturers, Distributors, Integrators, and End Users)

3.8 Porters Five Forces (Supplier Power, Buyer Power, Competitive Rivalry, Threat of Substitution, Barriers to Entry)

3.9 Competition Ecosystem (Market Share, Revenue Models, and Technological Differentiators)

4. India Industrial Robot Market Segmentation

4.1 By Product Type (In Value %)

4.1.1 Articulated Robots

4.1.2 SCARA Robots

4.1.3 Delta Robots

4.1.4 Cartesian Robots

4.1.5 Collaborative Robots (Cobots)

4.2 By Application (In Value %)

4.2.1 Automotive Industry

4.2.2 Electronics and Electrical Industry

4.2.3 Food and Beverage Industry

4.2.4 Healthcare and Pharmaceuticals

4.2.5 Metal and Machinery Manufacturing

4.3 By Technology (In Value %)

4.3.1 Automated Welding

4.3.2 Assembly Line Automation

4.3.3 Pick and Place Automation

4.3.4 Material Handling Automation

4.3.5 Quality Inspection

4.4 By End User (In Value %)

4.4.1 Manufacturing Industry

4.4.2 Logistics and Warehousing

4.4.3 Agriculture

4.4.4 Healthcare

4.4.5 Aerospace

4.5 By Region (In Value %)

4.5.1 North

4.5.2 South

4.5.3 East

4.5.4 West

5. India Industrial Robot Market Competitive Analysis

5.1 Detailed Profiles of Major Companies

5.1.1 ABB Ltd.

5.1.2 Fanuc India Pvt. Ltd.

5.1.3 Yaskawa India Pvt. Ltd.

5.1.4 Kuka Robotics India Pvt. Ltd.

5.1.5 Mitsubishi Electric India Pvt. Ltd.

5.1.6 Panasonic India Pvt. Ltd.

5.1.7 Hyundai Robotics

5.1.8 Universal Robots

5.1.9 Omron Automation Pvt. Ltd.

5.1.10 Siasun India

5.1.11 Toshiba Machine Co. Ltd.

5.1.12 Delta Electronics India

5.1.13 Rockwell Automation India Pvt. Ltd.

5.1.14 Adept Technology India

5.1.15 Epson Robots

5.2 Cross Comparison Parameters (No. of Employees, Headquarters, Inception Year, Revenue, Product Portfolio, Global Presence, Technological Advancements, Recent Acquisitions)

5.3 Market Share Analysis (Segment-Wise Distribution, Technological Leadership, Regional Distribution)

5.4 Strategic Initiatives (Partnerships, Product Launches, Geographical Expansion)

5.5 Mergers and Acquisitions

5.6 Investment Analysis (Capex Plans, Facility Expansions)

5.7 Venture Capital Funding

5.8 Government Grants and Incentives

5.9 Private Equity Investments

6. India Industrial Robot Market Regulatory Framework

6.1 Industrial Automation Standards

6.2 Robotics Compliance Requirements

6.3 Certification Processes and ISO Standards

6.4 Government Subsidies and Incentive Schemes

7. India Industrial Robot Future Market Size (In USD Bn)

7.1 Future Market Size Projections

7.2 Key Factors Driving Future Market Growth

8. India Industrial Robot Future Market Segmentation

8.1 By Product Type (In Value %)

8.2 By Application (In Value %)

8.3 By Technology (In Value %)

8.4 By End User (In Value %)

8.5 By Region (In Value %)

9. India Industrial Robot Market Analysts Recommendations

9.1 TAM/SAM/SOM Analysis

9.2 Customer Cohort Analysis

9.3 Marketing Initiatives

9.4 White Space Opportunity Analysis

Disclaimer Contact UsResearch Methodology

Step 1: Identification of Key Variables

The initial phase involves mapping out the entire ecosystem of the India Industrial Robot Market, encompassing all major stakeholders. This includes extensive desk research using proprietary databases and secondary sources to gather relevant information. The objective is to identify key market variables such as demand drivers, technological advancements, and regulatory frameworks.

Step 2: Market Analysis and Construction

In this phase, historical data on market penetration, product development, and industry revenue is compiled. The analysis focuses on product innovation, the market presence of robotics manufacturers, and trends influencing the adoption of automation across industries. This step also evaluates demand fluctuations and service provider market share.

Step 3: Hypothesis Validation and Expert Consultation

Market hypotheses are validated through structured interviews with key industry stakeholders, including robotics manufacturers, end users, and industry experts. These interviews provide critical insights into market trends, challenges, and operational aspects, which are crucial for the final market analysis.

Step 4: Research Synthesis and Final Output

The final phase involves synthesizing all research findings into a comprehensive report. Detailed insights from manufacturers, including product performance, market penetration, and future outlook, are incorporated into the report to ensure that it provides actionable insights and accurate forecasts.

Frequently Asked Questions

01. How big is the India Industrial Robot Market?

The India Industrial Robot Market was valued at USD 2.6 billion and is driven by the increasing adoption of automation in manufacturing industries, supported by government initiatives like "Make in India" and the rising need for precision in industrial operations.

02. What are the challenges in the India Industrial Robot Market?

Challenges in the India Industrial Robot Market include high initial capital investment, lack of skilled workforce for robot operation and maintenance, and integration difficulties with existing industrial setups, particularly in smaller businesses.

03. Who are the major players in the India Industrial Robot Market?

Key players in the India Industrial Robot Market include ABB Ltd., Fanuc India Pvt. Ltd., Yaskawa India Pvt. Ltd., Kuka Robotics India Pvt. Ltd., and Mitsubishi Electric India Pvt. Ltd. These companies dominate due to their technological innovations, strong industry partnerships, and local manufacturing capabilities.

04. What are the growth drivers of the India Industrial Robot Market?

The India Industrial Robot Market is driven by factors such as the rising need for automation in manufacturing, labor shortages in key industries, government support for industrial modernization, and advancements in robotics technologies, including AI and machine learning.

Why Buy From Us?

What makes us stand out is that our consultants follows Robust, Refine and Result (RRR) methodology. i.e. Robust for clear definitions, approaches and sanity checking, Refine for differentiating respondents facts and opinions and Result for presenting data with story

We have set a benchmark in the industry by offering our clients with syndicated and customized market research reports featuring coverage of entire market as well as meticulous research and analyst insights.

While we don't replace traditional research, we flip the method upside down. Our dual approach of Top Bottom & Bottom Top ensures quality deliverable by not just verifying company fundamentals but also looking at the sector and macroeconomic factors.

With one step in the future, our research team constantly tries to show you the bigger picture. We help with some of the tough questions you may encounter along the way: How is the industry positioned? Best marketing channel? KPI's of competitors? By aligning every element, we help maximize success.

Our report gives you instant access to the answers and sources that other companies might choose to hide. We elaborate each steps of research methodology we have used and showcase you the sample size to earn your trust.

If you need any support, we are here! We pride ourselves on universe strength, data quality, and quick, friendly, and professional service.