India Industrial Robotics Market Outlook to 2030

Region:Asia

Author(s):Naman Rohilla

Product Code:KROD3462

November 2024

97

About the Report

India Industrial Robotics Market Overview

- The India Industrial Robotics market is valued at USD 158 million, driven by increased demand for automation in key sectors such as automotive, electronics, and manufacturing. This growth is fueled by the rising need for enhanced production efficiency and the adoption of advanced technologies such as Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT). Furthermore, the introduction of government initiatives like the "Make in India" program has spurred the domestic manufacturing sector, further contributing to the rising demand for industrial robots.

- Mumbai and Bengaluru are dominant cities in the Indian industrial robotics market, owing to their strong presence of automotive and electronics manufacturing hubs. These cities benefit from a well-developed industrial ecosystem, availability of skilled labor, and proximity to key technology centers. Moreover, foreign direct investments (FDI) in these regions have boosted the establishment of robotics manufacturing units, making them key players in the sectors development and adoption of advanced robotics systems.

- Cloud robotics is transforming the way industrial robots are monitored and controlled. Cloud-based systems allow for real-time data analytics, remote diagnostics, and better coordination across multiple units. In 2023, the Indian Ministry of Electronics and IT recorded a 17% increase in cloud robotics adoption, particularly in the automotive and aerospace sectors. Cloud-based systems are especially valuable for predictive maintenance, reducing downtime and enhancing production efficiency.

India Industrial Robotics Market Segmentation

The India Industrial Robotics Market is segmented by robot type, industry vertical, application, component, and geographical region.

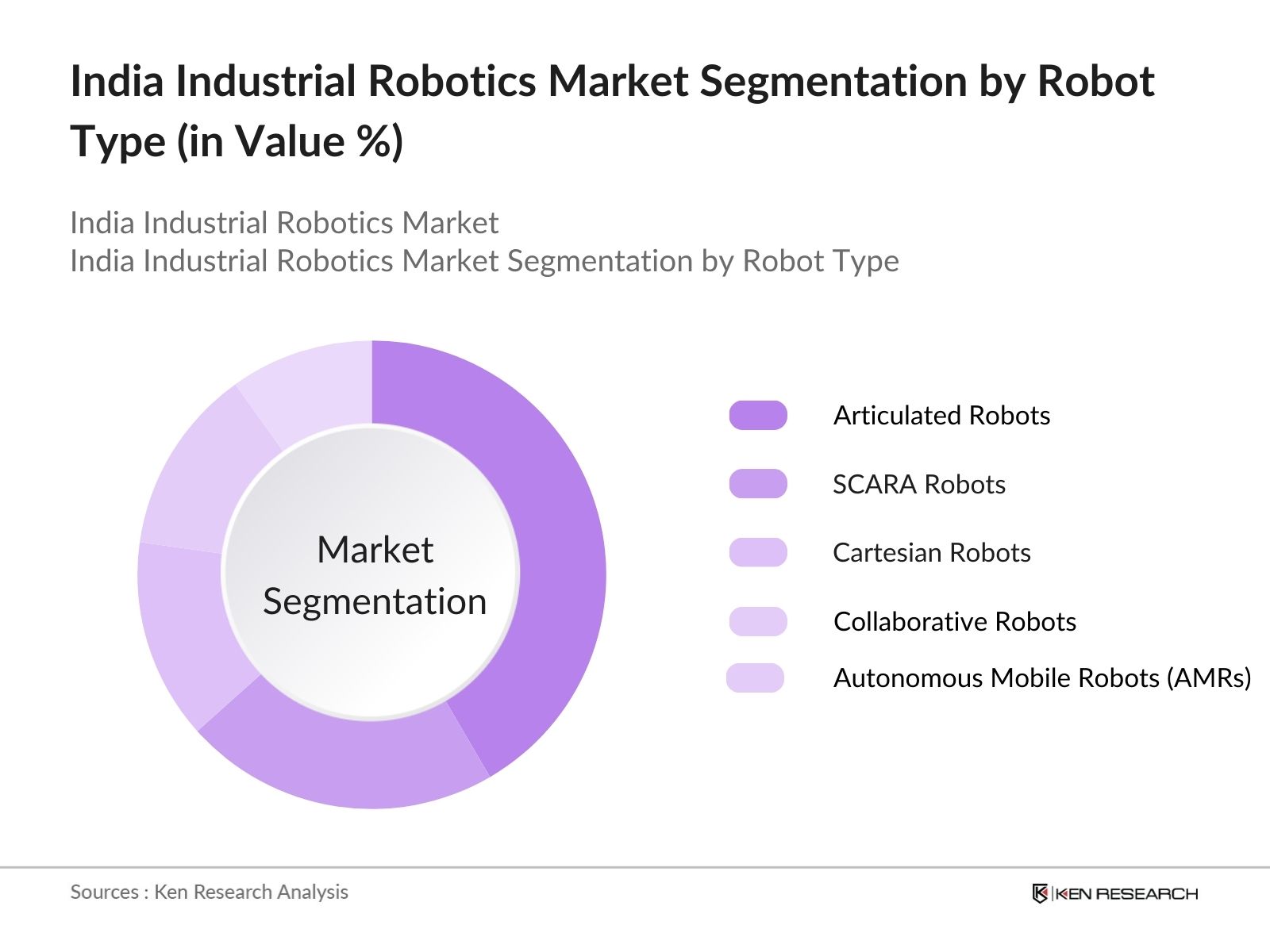

- By Robot Type: The India Industrial Robotics market is segmented by robot type into articulated robots, SCARA robots, Cartesian robots, collaborative robots, and autonomous mobile robots (AMRs). Among these, articulated robots hold the dominant market share due to their versatility in performing complex tasks across multiple industries such as automotive and electronics. The ability of articulated robots to handle intricate assembly tasks with precision and high payload capacity makes them the preferred choice for manufacturers looking to enhance productivity and reduce operational costs.

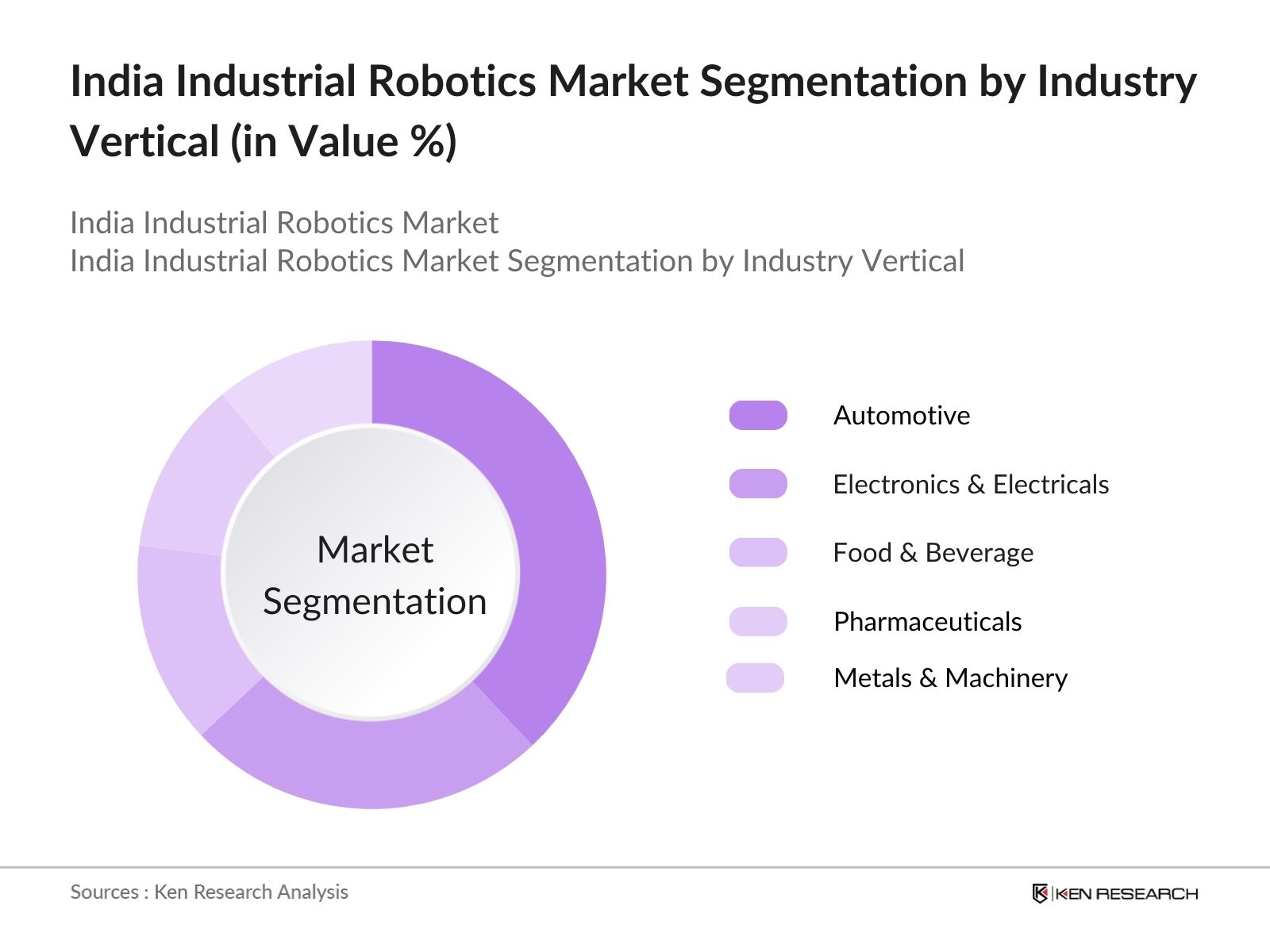

- By Industry Vertical: The market is also segmented by industry verticals, including automotive, electronics and electricals, food and beverage, pharmaceuticals, and metals and machinery. The automotive industry dominates the market due to its high reliance on automation to streamline production processes, improve quality control, and enhance efficiency. The increasing demand for electric vehicles (EVs) and the need to produce them efficiently has further contributed to the growth of industrial robotics in this sector.

India Industrial Robotics Market Competitive Landscape

The India Industrial Robotics market is dominated by a mix of global and domestic players. These companies are at the forefront of driving innovation, investing in research and development, and forming strategic partnerships to expand their market share. The competitive landscape is characterized by a strong presence of global robotics companies and an increasing number of local manufacturers catering to the specific needs of the Indian market.

|

Company |

Establishment Year |

Headquarters |

Revenue (2023, USD Bn) |

No. of Employees |

R&D Expenditure |

Product Portfolio |

Global Presence |

Key Clients |

Strategic Alliances |

|

ABB Ltd. |

1988 |

Zurich, Switzerland |

- |

- |

- |

- |

- |

- |

- |

|

Fanuc Corporation |

1972 |

Oshino, Japan |

- |

- |

- |

- |

- |

- |

- |

|

KUKA Robotics |

1995 |

Augsburg, Germany |

- |

- |

- |

- |

- |

- |

- |

|

Yaskawa Electric Corp |

1915 |

Kitakyushu, Japan |

- |

- |

- |

- |

- |

- |

- |

|

Bharat Fritz Werner Ltd. (BFW) |

1961 |

Bengaluru, India |

- |

- |

- |

- |

- |

- |

- |

India Industrial Robotics Market Analysis

India Industrial Robotics Market Growth Drivers

- Adoption of Automation in Manufacturing (Factory Automation, Industry 4.0): Indias manufacturing sector is rapidly adopting automation technologies driven by Industry 4.0 principles, including the Internet of Things (IoT) and smart machinery. The National Strategy for AI released by NITI Aayog highlights that factory automation in India is projected to grow, contributing to operational efficiency by minimizing human errors. The automotive industry, which constitutes over 7% of Indias GDP, is one of the main sectors adopting these technologies. In 2023, the number of automated factories increased by 25% across key industrial clusters in Pune and Chennai.

- Increasing Demand for Precision and Efficiency in Production: Precision and efficiency have become vital to maintaining competitiveness in the global market. According to the Federation of Indian Chambers of Commerce & Industry (FICCI), industries such as automotive and electronics demand robotic systems that ensure high precision and operational efficiency. In the aerospace sector alone, India saw a 15% rise in demand for precision robotics between 2022 and 2024 to meet strict international quality standards for aircraft manufacturing. This demand is crucial for industries seeking to reduce wastage and operational costs.

- Rising Labor Costs and Workforce Shortage: Labor costs in India have risen by an average of INR 500 per day in manufacturing hubs like Gujarat and Tamil Nadu, putting pressure on industries to explore alternatives like robotics. The Ministry of Labor and Employment reported that manufacturing units have faced a 10% reduction in available skilled labor due to migration towards service sectors and other urban employment opportunities. The deployment of robots is seen as a solution to address both workforce shortages and increasing labor costs, leading to a more stable production process.

India Industrial Robotics Market Challenges

- High Initial Capital Investment (Installation, Setup): The installation and setup of industrial robots require a significant capital outlay, with costs reaching INR 10-20 million for basic factory automation systems, according to the Ministry of Heavy Industries (MHI). These high costs are a deterrent, particularly for small and medium-sized enterprises (SMEs), which account for 29% of Indias GDP. Despite the long-term cost savings, many manufacturers find it challenging to justify the upfront investment, especially without clear short-term returns.

- Integration Complexities with Legacy Systems: Integrating modern industrial robots with legacy manufacturing systems presents challenges, particularly for older factories. According to a report by the Confederation of Indian Industry (CII), over 35% of Indian manufacturing plants still rely on legacy systems built more than two decades ago. This results in compatibility issues, causing delays and additional costs in reconfiguration and testing. These complexities can hinder the deployment of new robotic systems, affecting productivity and operational efficiency.

India Industrial Robotics Market Future Outlook

Over the next five years, the India Industrial Robotics market is expected to experience robust growth, driven by several factors. These include the continuous demand for automation in the automotive and electronics sectors, the expansion of domestic manufacturing capabilities, and government support through initiatives like "Make in India." Additionally, advancements in AI and collaborative robotics are expected to create new opportunities in small and medium-sized enterprises (SMEs), which are increasingly adopting robotics solutions to enhance efficiency and reduce labour costs. This trend is anticipated to strengthen India's position as a key player in the global industrial robotics market.

India Industrial Robotics Market Opportunities

- Integration of Collaborative Robots (Cobots): Collaborative robots, or cobots, offer a unique opportunity for industries aiming to integrate automation without extensive reconfiguration of existing systems. According to the International Federation of Robotics, cobot installations in India increased by 18% in 2023, particularly in the automotive and electronics sectors. Cobots are easier to program, cheaper to install, and can work alongside human workers, reducing the need for full-scale automation while improving productivity. Indian SMEs are particularly exploring cobots as an entry-level investment into robotics.

- Expansion into SMEs and MSMEs Sectors: The potential for robotics expansion into Indias SME and MSME sectors is vast, given that these businesses represent 95% of all industrial units and contribute over 40% to Indias exports. The Ministry of MSMEs has launched several initiatives, including the "Lean Manufacturing Scheme," which offers financial support for technology upgrades, including robotics. In 2023, over 1,500 MSMEs received government subsidies to adopt automation technologies, signalling strong future growth opportunities in these sectors.

|

|

Segment |

Sub-Segments |

|

Robot Type |

Articulated Robots SCARA Robots Cartesian Robots Collaborative Robots Autonomous Mobile Robots |

|

Industry Vertical |

Automotive Electronics & Electricals Food & Beverage Pharmaceuticals Metals & Machinery |

|

Application |

Material Handling Assembly & Disassembly Welding & Soldering Painting & Coating Quality Inspection |

|

Component |

Robotic Arms Sensors & Actuators Controllers Drives & Power Supply Software & AI Integration |

|

Region |

Northern India Southern India Eastern India Western India |

India Industrial Robotics Major Market Players

- ABB Ltd.

- Fanuc Corporation

- KUKA Robotics

- Yaskawa Electric Corp

- Mitsubishi Electric

- Panasonic Corporation

- Universal Robots

- Toshiba Machine Co. Ltd.

- Omron Adept Technologies

- NACHI-Fujikoshi Corp

- Seiko Epson Corporation

- Staubli Robotics

- Techman Robot

- Delta Electronics

- Bharat Fritz Werner Ltd. (BFW)

Products

Key Target Audience

Automotive Manufacturers

Electronics and Electricals Companies

Food and Beverage Manufacturers

Pharmaceuticals and Healthcare Companies

Metals and Machinery Companies

Investment and Venture Capitalist Firms

Government and Regulatory Bodies (Ministry of Heavy Industries, Department for Promotion of Industry and Internal Trade)

Robotics System Integrators and Software Providers

Table of Contents

1. India Industrial Robotics Market Overview

1.1. Definition and Scope

1.2. Market Taxonomy

1.3. Market Growth Rate

1.4. Market Segmentation Overview

2. India Industrial Robotics Market Size (In USD Bn)

2.1. Historical Market Size

2.2. Year-On-Year Growth Analysis

2.3. Key Market Developments and Milestones

3. India Industrial Robotics Market Analysis

3.1. Growth Drivers

3.1.1. Technological Advancements in AI and Machine Learning

3.1.2. Adoption of Automation in Manufacturing (Factory Automation, Industry 4.0)

3.1.3. Increasing Demand for Precision and Efficiency in Production

3.1.4. Rising Labor Costs and Workforce Shortage

3.2. Market Challenges

3.2.1. High Initial Capital Investment (Installation, Setup)

3.2.2. Integration Complexities with Legacy Systems

3.2.3. Lack of Skilled Operators and Maintenance Personnel

3.3. Opportunities

3.3.1. Integration of Collaborative Robots (Cobots)

3.3.2. Expansion into SMEs and MSMEs Sectors

3.3.3. Export Potential to Emerging Markets (ASEAN, Middle East)

3.4. Trends

3.4.1. Increased Deployment of Autonomous Mobile Robots (AMRs)

3.4.2. Implementation of AI in Robot Programming and Operations

3.4.3. Adoption of Cloud Robotics for Remote Control and Monitoring

3.5. Government Regulations

3.5.1. "Make in India" Initiative Driving Industrial Automation

3.5.2. Tax Incentives and Subsidies for Automation Adoption

3.5.3. Import/Export Regulations for Robotics Components and Machinery

3.5.4. Employment Laws and Regulations Affecting Robotics Implementation

3.6. SWOT Analysis

3.7. Stakeholder Ecosystem

3.8. Porters Five Forces Analysis

3.9. Competition Ecosystem

4. India Industrial Robotics Market Segmentation

4.1. By Robot Type (In Value %)

4.1.1. Articulated Robots

4.1.2. SCARA Robots

4.1.3. Cartesian Robots

4.1.4. Collaborative Robots (Cobots)

4.1.5. Autonomous Mobile Robots (AMRs)

4.2. By Industry Vertical (In Value %)

4.2.1. Automotive

4.2.2. Electronics and Electricals

4.2.3. Food and Beverage

4.2.4. Pharmaceuticals

4.2.5. Metals and Machinery

4.3. By Application (In Value %)

4.3.1. Material Handling

4.3.2. Assembly and Disassembly

4.3.3. Welding and Soldering

4.3.4. Painting and Coating

4.3.5. Quality Inspection

4.4. By Component (In Value %)

4.4.1. Robotic Arms

4.4.2. Sensors and Actuators

4.4.3. Controllers

4.4.4. Drives and Power Supply

4.4.5. Software and AI Integration

4.5. By Region (In Value %)

4.5.1. Northern India

4.5.2. Southern India

4.5.3. Eastern India

4.5.4. Western India

5. India Industrial Robotics Market Competitive Analysis

5.1. Detailed Profiles of Major Companies

5.1.1. ABB Ltd.

5.1.2. Fanuc Corporation

5.1.3. KUKA Robotics

5.1.4. Yaskawa Electric Corporation

5.1.5. Mitsubishi Electric

5.1.6. Panasonic Corporation

5.1.7. Universal Robots

5.1.8. Toshiba Machine Co. Ltd.

5.1.9. Omron Adept Technologies

5.1.10. NACHI-Fujikoshi Corp

5.1.11. Seiko Epson Corporation

5.1.12. Staubli Robotics

5.1.13. Techman Robot

5.1.14. Delta Electronics

5.1.15. Bharat Fritz Werner Ltd. (BFW)

5.2. Cross Comparison Parameters

5.3. Market Share Analysis

5.4. Strategic Initiatives

5.5. Mergers and Acquisitions

5.6. Investment Analysis

6. India Industrial Robotics Market Regulatory Framework

6.1. National Robotics Mission

6.2. Industry Standards for Automation and Robotics

6.3. Safety Regulations for Robotics in Factories

6.4. Compliance Requirements for Robotic Products

7. India Industrial Robotics Market Future Market Size (In USD Bn)

7.1. Future Market Size Projections

7.2. Key Factors Driving Future Market Growth

8. India Industrial Robotics Market Future Market Segmentation

8.1. By Robot Type (In Value %)

8.2. By Industry Vertical (In Value %)

8.3. By Application (In Value %)

8.4. By Component (In Value %)

8.5. By Region (In Value %)

9. India Industrial Robotics Market Analysts Recommendations

9.1. TAM/SAM/SOM Analysis

9.2. Customer Cohort Analysis

9.3. Marketing Initiatives

9.4. White Space Opportunity Analysis

Disclaimer Contact UsResearch Methodology

Step 1: Identification of Key Variables

The initial phase involves constructing an ecosystem map encompassing all major stakeholders within the India Industrial Robotics Market. This step is underpinned by extensive desk research, utilizing a combination of secondary and proprietary databases to gather comprehensive industry-level information. The primary objective is to identify and define the critical variables that influence market dynamics.

Step 2: Market Analysis and Construction

In this phase, we compile and analyze historical data related to the India Industrial Robotics Market. This includes assessing market penetration, the ratio of robot types to industry verticals, and the resultant revenue generation. We further evaluate service quality statistics to ensure the reliability and accuracy of the revenue estimates.

Step 3: Hypothesis Validation and Expert Consultation

Market hypotheses are developed and subsequently validated through computer-assisted telephone interviews (CATIS) with industry experts representing a diverse array of companies. These consultations provide valuable operational and financial insights directly from industry practitioners, which are instrumental in refining and corroborating the market data.

Step 4: Research Synthesis and Final Output

The final phase involves direct engagement with multiple robotics manufacturers to acquire detailed insights into product segments, sales performance, consumer preferences, and other pertinent factors. This interaction serves to verify and complement the statistics derived from the bottom-up approach, thereby ensuring a comprehensive, accurate, and validated analysis of the India Industrial Robotics market.

Frequently Asked Questions

01. How big is the India Industrial Robotics Market?

The India Industrial Robotics market is valued at USD 158 million, driven by the rising demand for automation across industries like automotive, electronics, and manufacturing, along with the introduction of advanced technologies such as AI and ML.

02. What are the challenges in the India Industrial Robotics Market?

Key challenges include the high initial capital investment required for industrial robotics systems, integration complexities with existing infrastructure, and the lack of a skilled workforce capable of operating and maintaining these robots.

03. Who are the major players in the India Industrial Robotics Market?

Major players include ABB Ltd., Fanuc Corporation, KUKA Robotics, Yaskawa Electric Corp, and Bharat Fritz Werner Ltd. These companies lead the market with their extensive product offerings, robust R&D investments, and strategic partnerships.

04. What are the growth drivers of the India Industrial Robotics Market?

The market is driven by the growing need for automation in key sectors like automotive, the implementation of government initiatives to promote domestic manufacturing, and advancements in AI and robotics technologies that enhance production efficiency.

Why Buy From Us?

What makes us stand out is that our consultants follows Robust, Refine and Result (RRR) methodology. i.e. Robust for clear definitions, approaches and sanity checking, Refine for differentiating respondents facts and opinions and Result for presenting data with story

We have set a benchmark in the industry by offering our clients with syndicated and customized market research reports featuring coverage of entire market as well as meticulous research and analyst insights.

While we don't replace traditional research, we flip the method upside down. Our dual approach of Top Bottom & Bottom Top ensures quality deliverable by not just verifying company fundamentals but also looking at the sector and macroeconomic factors.

With one step in the future, our research team constantly tries to show you the bigger picture. We help with some of the tough questions you may encounter along the way: How is the industry positioned? Best marketing channel? KPI's of competitors? By aligning every element, we help maximize success.

Our report gives you instant access to the answers and sources that other companies might choose to hide. We elaborate each steps of research methodology we have used and showcase you the sample size to earn your trust.

If you need any support, we are here! We pride ourselves on universe strength, data quality, and quick, friendly, and professional service.