KSA Automotive Plastics Market outlook to 2030

Region:Middle East

Author(s):Dev Chawla

Product Code:KRO003

June 2025

80

About the Report

KSA Automotive Plastics Market Overview

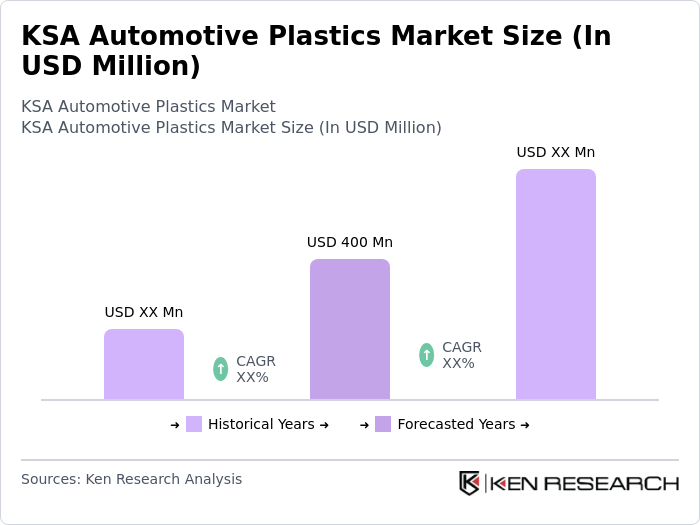

- The KSA Automotive Plastics Market is valued at USD 400 million, based on a five-year historical analysis. This growth is primarily driven by the increasing demand for lightweight materials in the automotive sector, which enhances fuel efficiency and reduces emissions. The rising trend of electric vehicles and the need for sustainable materials further contribute to the market's expansion.

- Key players in this market include Riyadh, Jeddah, and Dammam, which dominate due to their strategic locations, robust industrial infrastructure, and proximity to major automotive manufacturers. These cities serve as hubs for automotive production and distribution, attracting investments and fostering innovation in automotive plastics.

- In 2023, the Saudi government implemented regulations aimed at promoting the use of recyclable materials in automotive manufacturing. This initiative mandates that at least 30% of the materials used in vehicle production must be recyclable, encouraging manufacturers to adopt sustainable practices and reduce environmental impact.

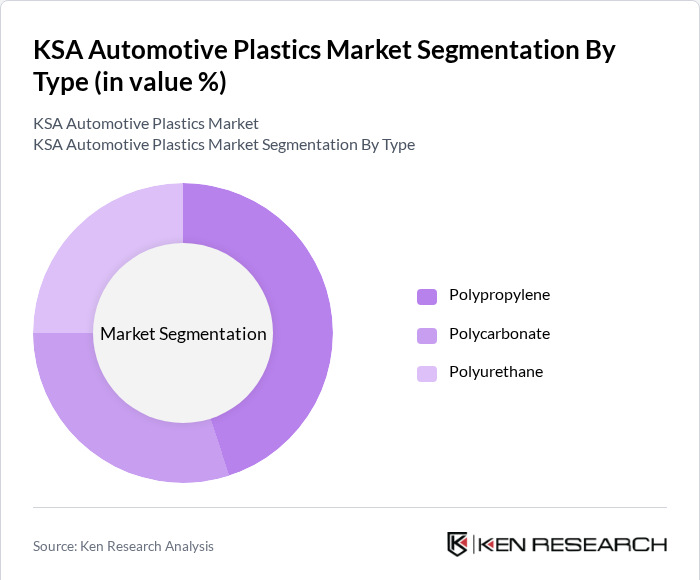

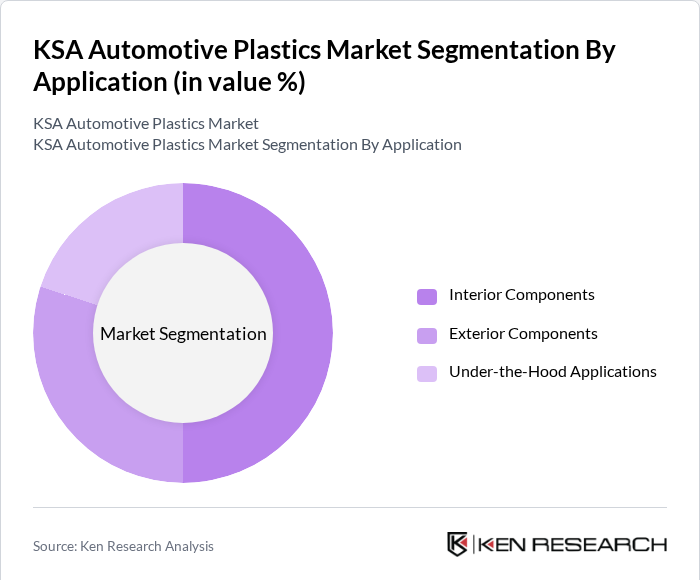

KSA Automotive Plastics Market Segmentation

By Type: The automotive plastics market can be segmented into several types, including polypropylene, polycarbonate, and polyurethane. Among these, polypropylene is the dominant sub-segment due to its lightweight properties, cost-effectiveness, and versatility in various automotive applications. It is widely used in interior and exterior components, making it a preferred choice for manufacturers aiming to enhance vehicle performance while reducing weight. The increasing focus on fuel efficiency and emissions reduction further drives the demand for polypropylene in the automotive sector.

By Application: The applications of automotive plastics include interior components, exterior components, and under-the-hood applications. The interior components sub-segment is leading the market, driven by consumer preferences for aesthetics, comfort, and functionality. Automotive manufacturers are increasingly utilizing plastics for dashboards, seating, and trim, as these materials offer design flexibility and weight reduction. The trend towards enhanced vehicle interiors, coupled with the growing demand for electric vehicles, is expected to sustain the growth of this sub-segment.

KSA Automotive Plastics Market Competitive Landscape

The KSA Automotive Plastics Market is characterized by a competitive landscape with several key players, including SABIC, BASF, and LyondellBasell. These companies are known for their innovative approaches and extensive product portfolios, which cater to the diverse needs of the automotive industry. The market is moderately concentrated, with a mix of local and international firms striving to enhance their market presence through strategic partnerships and technological advancements.

KSA Automotive Plastics Market Industry Analysis

KSA Automotive Plastics Market Industry Analysis

Growth Drivers

- Increasing Demand for Lightweight Materials: The KSA automotive sector is witnessing a significant shift towards lightweight materials, with plastics playing a crucial role. The Saudi automotive industry, which achieved an exponenetial growth in recent years, is increasingly adopting plastics to reduce vehicle weight, thereby enhancing performance and lowering emissions, aligning with global sustainability goals.

- Accelerated Growth in Electric Vehicles and Infrastructure Development: Saudi Arabia’s EV market is rapidly growing, supported by government incentives and Vision 2030 goals. With plans to install 5,000 fast-charging stations by 2030, the Kingdom is boosting EV adoption, promoting local manufacturing, and advancing sustainable transportation to meet environmental targets and diversify its economy.

- Expansion of the Automotive Industry: The automotive industry in KSA is projected to grow at a rate of 5% annually, fueled by increased local manufacturing and foreign investments. In 2024, the production of vehicles is expected to exceed 500,000 units, creating a robust demand for automotive plastics. This growth is supported by government initiatives aimed at diversifying the economy and reducing reliance on oil, thereby enhancing the market for automotive plastics significantly.

Market Challenges

- Fluctuating Raw Material Prices: The automotive plastics market in KSA faces challenges due to volatile raw material prices, particularly for petrochemicals. In 2024, the price of polypropylene is expected to fluctuate between USD 1,200 and USD 1,500 per ton, impacting production costs. This instability can lead to increased manufacturing expenses, forcing companies to either absorb costs or pass them onto consumers, which may hinder market growth and profitability.

- Stringent Environmental Regulations: Compliance with environmental regulations poses a significant challenge for automotive plastics manufacturers in KSA. Adapting to these regulations necessitates investment in sustainable practices and technologies, which can strain financial resources and slow down production processes, ultimately affecting competitiveness in the market.

KSA Automotive Plastics Market Future Outlook

The KSA automotive plastics market is poised for transformative growth, driven by technological advancements and evolving consumer preferences. By 2029, the integration of smart technologies in automotive plastics will enhance functionality and appeal. Additionally, the shift towards bio-based materials will align with global sustainability trends, fostering innovation. As electric vehicle production ramps up, the demand for specialized plastics will surge, creating new avenues for growth and investment in the sector, ultimately reshaping the automotive landscape in KSA.

Market Opportunities

- Growth in Electric Vehicle Production: The rise of electric vehicles (EVs) in KSA presents a significant opportunity for automotive plastics. With EV production projected to reach 100,000 units by 2025, the demand for lightweight and durable plastic components will increase, providing manufacturers with a lucrative market segment to target, enhancing overall industry growth.

- Advancements in Recycling Technologies: Innovations in recycling technologies are creating opportunities for sustainable practices in the automotive plastics market. By 2027, the recycling rate for automotive plastics is projected to improve by 35%, driven by new processes that enhance material recovery. This trend not only supports environmental goals but also reduces raw material costs, making it an attractive opportunity for manufacturers.

Scope of the Report

| By Product Type |

Polypropylene Polycarbonate Polyurethane |

| By Application |

Interior Components Exterior Components Under-the-Hood Applications |

| By Vehicle Type |

Passenger Cars Commercial Vehicles Electric Vehicles |

| By Region |

Central Region Western Region Eastern Region |

| By Manufacturing Process |

Injection Molding Blow Molding Thermoforming |

Products

Key Target Audience

Investors and Venture Capitalist Firms

Government and Regulatory Bodies (e.g., Saudi Standards, Metrology and Quality Organization)

Automotive Manufacturers

Plastic Material Suppliers

Automotive Component Suppliers

Industry Associations (e.g., Saudi Automotive Manufacturers Association)

Logistics and Supply Chain Companies

Financial Institutions

Companies

Players Mentioned in the Report:

SABIC

BASF

LyondellBasell

Solvay

DuPont

PolyOne Corporation

Covestro AG

Mitsubishi Chemical Corporation

INEOS Styrolution

RTP Company

Table of Contents

1. KSA Automotive Plastics Market Overview

1.1. Definition and Scope

1.2. Market Taxonomy

1.3. Market Growth Rate

1.4. Market Segmentation Overview

2. KSA Automotive Plastics Market Size (In USD Bn)

2.1. Historical Market Size

2.2. Year-On-Year Growth Analysis

2.3. Key Market Developments and Milestones

3. KSA Automotive Plastics Market Analysis

3.1. Growth Drivers

3.1.1. Increasing demand for lightweight materials in automotive manufacturing

3.1.2. Rising focus on fuel efficiency and emissions reduction

3.1.3. Expansion of the automotive industry in the region

3.2. Market Challenges

3.2.1. Fluctuating raw material prices impacting production costs

3.2.2. Stringent environmental regulations affecting manufacturing processes

3.2.3. Competition from alternative materials such as metals and composites

3.3. Opportunities

3.3.1. Growth in electric vehicle production creating new demand for plastics

3.3.2. Advancements in recycling technologies enhancing sustainability

3.3.3. Increasing investments in automotive R&D for innovative plastic applications

3.4. Trends

3.4.1. Shift towards bio-based and biodegradable plastics in automotive applications

3.4.2. Integration of smart technologies in automotive plastics

3.4.3. Rising consumer preference for customized and aesthetic vehicle interiors

3.5. Government Regulation

3.5.1. Implementation of standards for automotive safety and performance

3.5.2. Regulations promoting the use of recyclable materials in automotive production

3.5.3. Policies encouraging local manufacturing and reducing import dependency

3.5.4. Compliance requirements for emissions and waste management in the automotive sector

3.6. SWOT Analysis

3.7. Stake Ecosystem

3.8. Porter’s Five Forces

3.9. Competition Ecosystem

4. KSA Automotive Plastics Market Segmentation

4.1. By Product Type

4.1.1 Polypropylene

4.1.2 Polycarbonate

4.1.3 Polyurethane

4.2. By Application

4.2.1 Interior Components

4.2.2 Exterior Components

4.2.3 Under-the-Hood Applications

4.3. By Vehicle Type

4.3.1 Passenger Cars

4.3.2 Commercial Vehicles

4.3.3 Electric Vehicles

4.4. By Region

4.4.1 Central Region

4.4.2 Western Region

4.4.3 Eastern Region

4.5. By Manufacturing Process

4.5.1 Injection Molding

4.5.2 Blow Molding

4.5.3 Thermoforming

5. KSA Automotive Plastics Market Competitive Analysis

5.1. Detailed Profiles of Major Companies

SABIC, BASF, LyondellBasell, Solvay, DuPont, PolyOne Corporation, Covestro AG, Mitsubishi Chemical Corporation, INEOS Styrolution, RTP Company

5.2. Cross Comparison Parameters

5.2.1. Market Share of Key Players

5.2.2. Product Portfolio Diversity

5.2.3. Geographic Presence and Distribution Channels

5.2.4. Research and Development Investment

5.2.5. Customer Satisfaction and Brand Loyalty Metrics

5.2.6. Pricing Strategies and Competitiveness

5.2.7. Sustainability Initiatives and Environmental Impact

5.2.8. Technological Advancements and Innovations

6. KSA Automotive Plastics Market Regulatory Framework

6.1. Environmental Standards

6.2. Compliance Requirements

6.3. Certification Processes

7. KSA Automotive Plastics Market Future Market Size (In USD Mn)

7.1. Future Market Size Projections

7.2. Key Factors Driving Future Market Growth

8. KSA Automotive Plastics Market Future Market Segmentation

8.1. By Product Type

8.1.1 Polypropylene

8.1.2 Polycarbonate

8.1.3 Polyurethane

8.2. By Application

8.2.1 Interior Components

8.2.2 Exterior Components

8.2.3 Under-the-Hood Applications

8.3. By Vehicle Type

8.3.1 Passenger Cars

8.3.2 Commercial Vehicles

8.3.3 Electric Vehicles

8.4. By Region

8.4.1 Central Region

8.4.2 Western Region

8.4.3 Eastern Region

8.5. By Manufacturing Process

8.5.1 Injection Molding

8.5.2 Blow Molding

8.5.3 Thermoforming

9. KSA Automotive Plastics Market Analysts’ Recommendations

9.1. TAM/SAM/SOM Analysis

9.2. Customer Cohort Analysis

9.3. Marketing Initiatives

9.4. White Space Opportunity Analysis

Research Methodology

Step 1: Identification of Key Variables

The initial phase involves constructing an ecosystem map encompassing all major stakeholders within the KSA Automotive Plastics Market. This step is underpinned by extensive desk research, utilizing a combination of secondary and proprietary databases to gather comprehensive industry-level information. The primary objective is to identify and define the critical variables that influence market dynamics.

Step 2: Market Analysis and Construction

In this phase, we will compile and analyze historical data pertaining to the KSA Automotive Plastics Market. This includes assessing market penetration, the ratio of marketplaces to service providers, and the resultant revenue generation. Furthermore, an evaluation of service quality statistics will be conducted to ensure the reliability and accuracy of the revenue estimates.

Step 3: Hypothesis Validation and Expert Consultation

Market hypotheses will be developed and subsequently validated through computer-assisted telephone interviews (CATIs) with industry experts representing a diverse array of companies. These consultations will provide valuable operational and financial insights directly from industry practitioners, which will be instrumental in refining and corroborating the market data.

Step 4: Research Synthesis and Final Output

The final phase involves direct engagement with multiple manufacturers to acquire detailed insights into product segments, sales performance, consumer preferences, and other pertinent factors. This interaction will serve to verify and complement the statistics derived from the bottom-up approach, thereby ensuring a comprehensive, accurate, and validated analysis of the KSA Automotive Plastics Market.

Frequently Asked Questions

01. How big is the KSA Automotive Plastics Market?

The KSA Automotive Plastics Market is valued at USD 400 million, driven by factors such as increasing demand, technological advancements, and supportive government initiatives.

02. What are the key challenges in the KSA Automotive Plastics Market?

Key challenges in the KSA Automotive Plastics Market include intense competition, regulatory complexities, and infrastructure limitations affecting market dynamics.

03. Who are the major players in the KSA Automotive Plastics Market?

Major players in the KSA Automotive Plastics Market include SABIC, BASF, LyondellBasell, Solvay, DuPont, among others.

04. What are the growth drivers for the KSA Automotive Plastics Market?

The primary growth drivers for the KSA Automotive Plastics Market are increasing consumer demand, favorable policies, innovation, and substantial investment inflows.

Why Buy From Us?

What makes us stand out is that our consultants follows Robust, Refine and Result (RRR) methodology. i.e. Robust for clear definitions, approaches and sanity checking, Refine for differentiating respondents facts and opinions and Result for presenting data with story

We have set a benchmark in the industry by offering our clients with syndicated and customized market research reports featuring coverage of entire market as well as meticulous research and analyst insights.

While we don't replace traditional research, we flip the method upside down. Our dual approach of Top Bottom & Bottom Top ensures quality deliverable by not just verifying company fundamentals but also looking at the sector and macroeconomic factors.

With one step in the future, our research team constantly tries to show you the bigger picture. We help with some of the tough questions you may encounter along the way: How is the industry positioned? Best marketing channel? KPI's of competitors? By aligning every element, we help maximize success.

Our report gives you instant access to the answers and sources that other companies might choose to hide. We elaborate each steps of research methodology we have used and showcase you the sample size to earn your trust.

If you need any support, we are here! We pride ourselves on universe strength, data quality, and quick, friendly, and professional service.