MEA Extrusion Machinery Market Outlook to 2030

Region:Middle East

Author(s):Meenakshi Bisht

Product Code:KROD7448

November 2024

88

About the Report

MEA Extrusion Machinery Market Overview

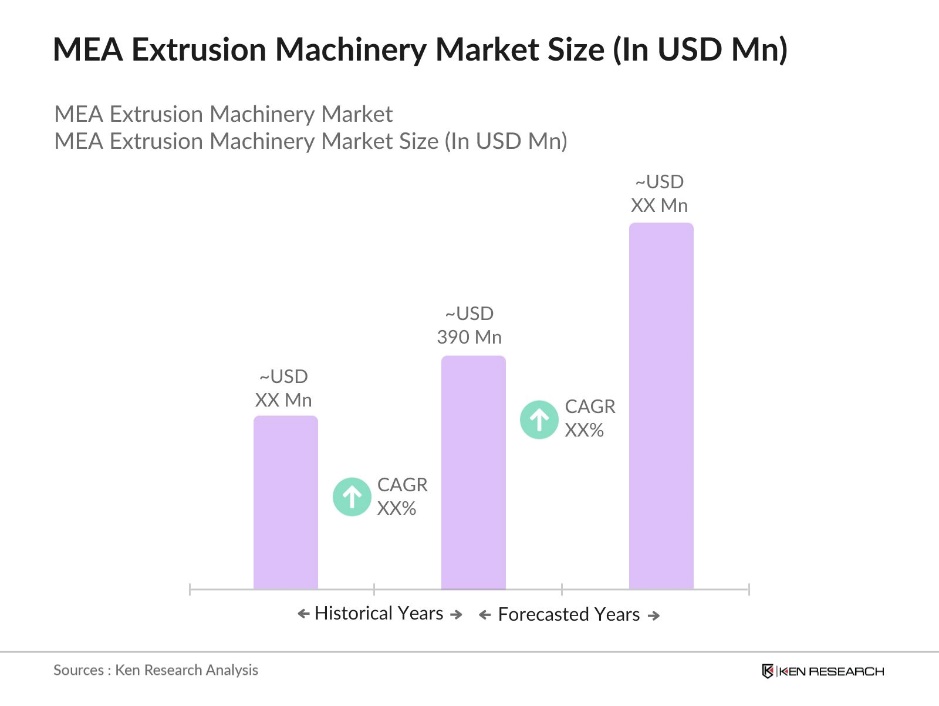

- The Middle East and Africa (MEA) extrusion machinery market is valued at USD 390 million, based on a five-year historical analysis. This growth is primarily driven by the increasing demand for plastic and metal products, coupled with substantial investments in the construction industry. The region's rapid industrialization and urbanization have further fueled the need for advanced extrusion machinery to meet the rising production requirements.

- Within the MEA region, countries such as Saudi Arabia, the United Arab Emirates, and South Africa dominate the extrusion machinery market. This dominance is attributed to their robust industrial sectors, significant infrastructure development projects, and favorable government policies that encourage manufacturing and industrial growth. These nations have established themselves as key players in the region's extrusion machinery industry.

- Manufacturers in the MEA region are increasingly required to comply with international standards, such as ISO 9001 and ISO 14001, to access global markets and ensure product quality and safety. Compliance with these standards improves the credibility and marketability of extrusion machinery. For example, ISO 9001 emphasizes quality management, which is critical for maintaining production efficiency and meeting customer expectations. The International Organization for Standardization (ISO) reports that over one million companies worldwide are certified to ISO 9001 standards, indicating the global shift towards quality assurance and standardization.

MEA Extrusion Machinery Market Segmentation

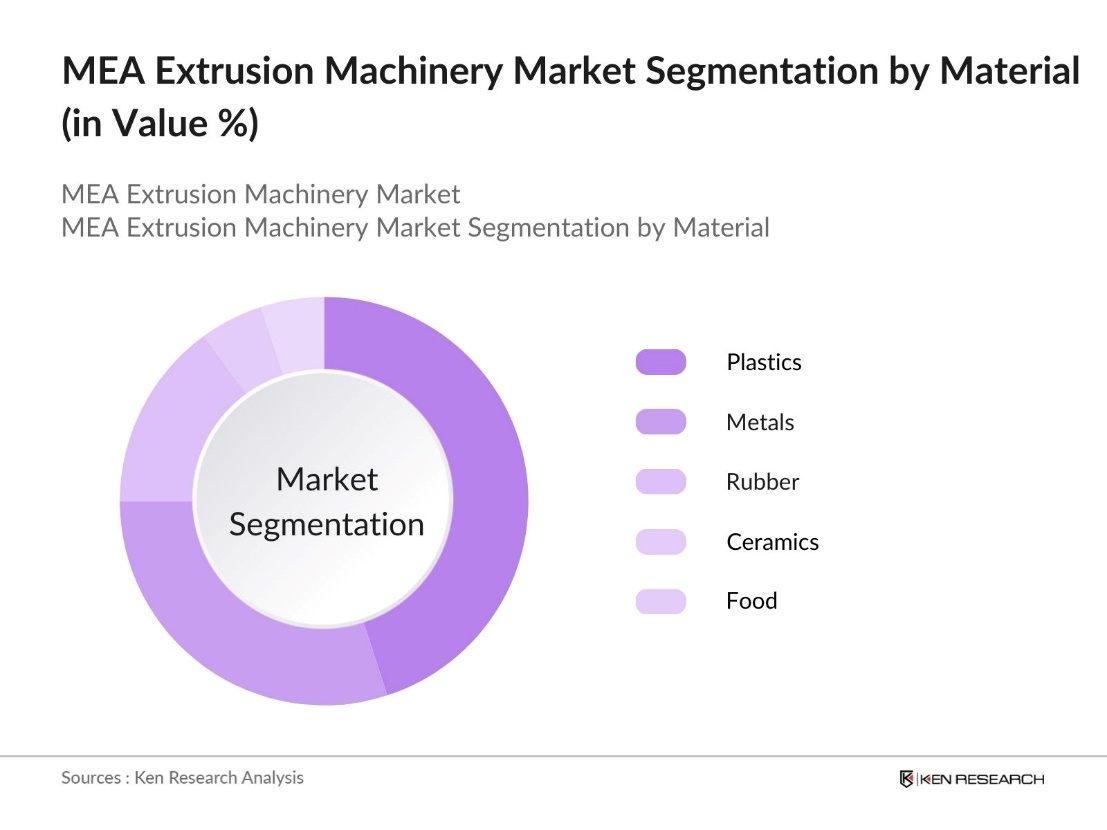

By Material: The market is segmented by material into plastics, metals, and others. Plastics have a dominant market share in the MEA extrusion machinery market under the segmentation by material. This is due to the widespread use of plastic products across various industries, including packaging, construction, and consumer goods. The versatility, cost-effectiveness, and lightweight nature of plastics make them a preferred choice, thereby driving the demand for plastic extrusion machinery.

By Type: The market is segmented by type into single-screw extruders, twin-screw extruders, and others. Single-screw extruders hold a dominant market share in the MEA extrusion machinery market under the segmentation by type. Their dominance is due to their simplicity, cost-effectiveness, and suitability for a wide range of applications, particularly in the processing of thermoplastics. Single-screw extruders are widely used in industries such as packaging and construction, contributing to their leading position in the market.

MEA Extrusion Machinery Market Competitive Landscape

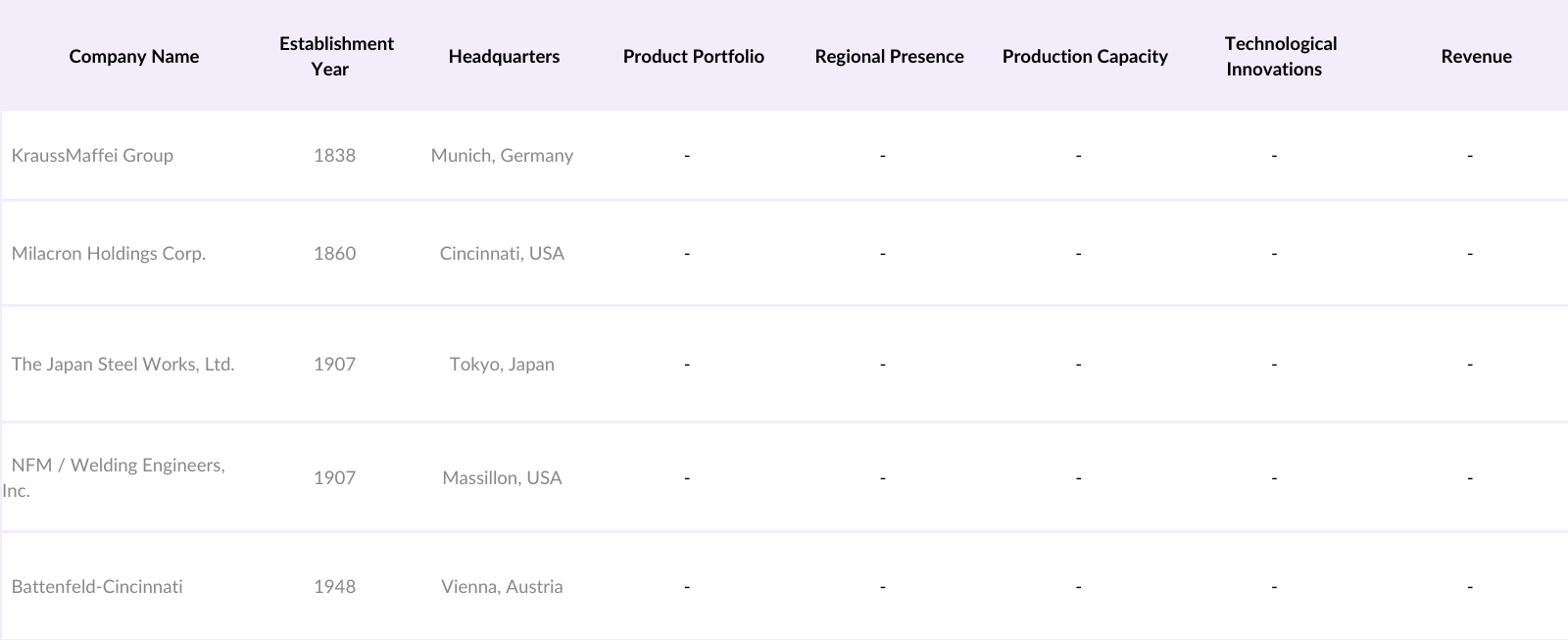

The MEA extrusion machinery market is characterized by the presence of several key players who contribute significantly to the industry's growth and development. The competitive landscape includes both regional and international companies that offer a diverse range of extrusion machinery solutions. Below is an overview of five major players in the market:

MEA Extrusion Machinery Industry Analysis

Growth Drivers

- Industrialization and Infrastructure Development: The Middle East and Africa (MEA) region has been experiencing significant industrialization and infrastructure development. For instance, the African Development Bank reported that Africa's infrastructure investment needs are estimated at $130$170 billion annually, with a financing gap of $68$108 billion. This surge in infrastructure projects, including roads, bridges, and housing, has increased the demand for construction materials, thereby driving the need for extrusion machinery used in producing components like pipes, profiles, and panels.

- Technological Advancements in Extrusion Processes: Advancements in extrusion technology have enhanced production efficiency and product quality. The adoption of twin-screw extruders, which offer better mixing capabilities and higher output rates, has become prevalent. Additionally, the integration of automation and control systems has streamlined operations, reducing labor costs and minimizing errors. These technological improvements have made extrusion machinery more attractive to industries in the MEA region, supporting market growth.

- Rising Demand in Packaging and Construction Sectors: The packaging industry in the MEA region has been expanding due to increased consumer goods consumption. According to the World Bank, the population of Sub-Saharan Africa grew by approximately 2.6% in 2022, leading to higher demand for packaged products. Similarly, the construction sector has seen growth, with the Middle East investing heavily in infrastructure projects. Extrusion machinery is essential in producing materials like plastic films for packaging and aluminum profiles for construction, driving market demand.

Market Challenges

- High Initial Capital Investment: Investing in advanced extrusion machinery requires substantial upfront capital, which poses a barrier for small and medium-sized enterprises (SMEs) in the MEA region. With limited access to financing options, especially in developing markets, many SMEs struggle to afford the high-cost technology needed to expand operations. This financial challenge restricts technology adoption and limits the growth potential of these businesses within the extrusion machinery market.

- Skilled Workforce Shortage: The operation and maintenance of advanced extrusion machinery require skilled technical expertise, which is in short supply across the MEA region. Limited access to technical education restricts the availability of qualified workers, making it challenging for companies to fully utilize advanced machinery. This skills gap affects productivity and hinders industry growth, as companies struggle to integrate and maintain the technology essential for modernized production.

MEA Extrusion Machinery Market Future Outlook

Over the next five years, the MEA extrusion machinery market is expected to show significant growth driven by continuous industrialization, infrastructure development, and increasing demand for plastic and metal products. The adoption of advanced extrusion technologies and the expansion of manufacturing capacities are anticipated to further propel market growth. Additionally, favorable government policies and investments in the manufacturing sector are likely to create new opportunities for market players.

Market Opportunities

- Expansion into Emerging Markets: Emerging markets in the MEA region, such as those in East Africa, are experiencing rapid economic growth and urbanization. These developments drive demand for construction materials and consumer goods, creating new opportunities for extrusion machinery manufacturers. By expanding into these growing markets, manufacturers can cater to the increased need for machinery that supports infrastructure and industrial expansion, fostering long-term growth within the region.

- Adoption of Energy-Efficient Machinery: As energy costs rise and environmental concerns grow, there is a heightened demand for energy-efficient extrusion machinery in the MEA region. Energy-efficient equipment offers operational cost savings and aligns with sustainability goals, making it increasingly attractive to industries. Manufacturers providing energy-saving machinery can leverage this trend to meet regional needs for cost-effective, eco-friendly solutions, positioning themselves as leaders in sustainable technology.

Scope of the Report

|

Material |

Plastics Metals Rubber Ceramics Food |

|

Type |

Single-Screw Extruders Twin-Screw Extruders Multi-Screw Extruders Ram Extruders Roller Extruders |

|

End-Use Industry |

Construction Automotive Packaging Consumer Goods Electrical & Electronics |

|

Process Type |

Hot Extrusion Cold Extrusion Warm Extrusion |

|

Region |

Saudi Arabia United Arab Emirates South Africa Egypt Nigeria |

Products

Key Target Audience

Extrusion Machinery Manufacturers

Plastic and Metal Product Manufacturers

Construction Companies

Automotive Manufacturers

Packaging Industry Players

Consumer Goods Manufacturers

Electrical & Electronics Manufacturers

Government and Regulatory Bodies (e.g., Ministry of Industry and Mineral Resources, Saudi Arabia)

Investors and venture capital Firms

Banks and Financial Institutions

Companies

Players Mentioned in the Report

KraussMaffei Group

Milacron Holdings Corp.

The Japan Steel Works, Ltd.

NFM / Welding Engineers, Inc.

Battenfeld-Cincinnati

Davis-Standard, LLC

Coperion GmbH

Leistritz AG

Toshiba Machine Co., Ltd.

Reifenhuser GmbH & Co. KG Maschinenfabrik

Table of Contents

1. MEA Extrusion Machinery Market Overview

1.1. Definition and Scope

1.2. Market Taxonomy

1.3. Market Growth Rate

1.4. Market Segmentation Overview

2. MEA Extrusion Machinery Market Size (In USD Mn)

2.1. Historical Market Size

2.2. Year-On-Year Growth Analysis

2.3. Key Market Developments and Milestones

3. MEA Extrusion Machinery Market Analysis

3.1. Growth Drivers

3.1.1. Industrialization and Infrastructure Development

3.1.2. Technological Advancements in Extrusion Processes

3.1.3. Rising Demand in Packaging and Construction Sectors

3.1.4. Government Initiatives and Investments

3.2. Market Challenges

3.2.1. High Initial Capital Investment

3.2.2. Skilled Workforce Shortage

3.2.3. Fluctuating Raw Material Prices

3.3. Opportunities

3.3.1. Expansion into Emerging Markets

3.3.2. Adoption of Energy-Efficient Machinery

3.3.3. Integration of Industry 4.0 Technologies

3.4. Trends

3.4.1. Shift Towards Sustainable and Recyclable Materials

3.4.2. Customization and Flexibility in Machinery Design

3.4.3. Increased Automation and Digitalization

3.5. Regulatory Landscape

3.5.1. Compliance with International Standards

3.5.2. Environmental Regulations and Emission Norms

3.5.3. Trade Policies and Tariffs

3.6. SWOT Analysis

3.7. Stakeholder Ecosystem

3.8. Porters Five Forces Analysis

3.9. Competitive Landscape

4. MEA Extrusion Machinery Market Segmentation

4.1. By Material (In Value %)

4.1.1. Plastics

4.1.2. Metals

4.1.3. Rubber

4.1.4. Ceramics

4.1.5. Food

4.2. By Type (In Value %)

4.2.1. Single-Screw Extruders

4.2.2. Twin-Screw Extruders

4.2.3. Multi-Screw Extruders

4.2.4. Ram Extruders

4.2.5. Roller Extruders

4.3. By End-Use Industry (In Value %)

4.3.1. Construction

4.3.2. Automotive

4.3.3. Packaging

4.3.4. Consumer Goods

4.3.5. Electrical & Electronics

4.4. By Process Type (In Value %)

4.4.1. Hot Extrusion

4.4.2. Cold Extrusion

4.4.3. Warm Extrusion

4.5. By Region (In Value %)

4.5.1. Saudi Arabia

4.5.2. United Arab Emirates

4.5.3. South Africa

4.5.4. Egypt

4.5.5. Nigeria

5. MEA Extrusion Machinery Market Competitive Analysis

5.1. Detailed Profiles of Major Companies

5.1.1. KraussMaffei Group

5.1.2. Milacron Holdings Corp.

5.1.3. The Japan Steel Works, Ltd.

5.1.4. NFM / Welding Engineers, Inc.

5.1.5. Battenfeld-Cincinnati

5.1.6. Davis-Standard, LLC

5.1.7. Coperion GmbH

5.1.8. Leistritz AG

5.1.9. Toshiba Machine Co., Ltd.

5.1.10. Reifenhuser GmbH & Co. KG Maschinenfabrik

5.1.11. Gneuss Kunststofftechnik GmbH

5.1.12. Brckner Group GmbH

5.1.13. SML Maschinengesellschaft mbH

5.1.14. Fong Kee International Machinery Co., Ltd.

5.1.15. Alpha Marathon Technologies Group

5.2. Cross Comparison Parameters (Product Portfolio, Regional Presence, Production Capacity, Technological Innovations, Market Share, Revenue, Strategic Initiatives, R&D Investments)

5.3. Market Share Analysis

5.4. Strategic Initiatives

5.5. Mergers and Acquisitions

5.6. Investment Analysis

5.7. Venture Capital Funding

5.8. Government Grants

5.9. Private Equity Investments

6. MEA Extrusion Machinery Market Regulatory Framework

6.1. Industry Standards and Certifications

6.2. Environmental Compliance

6.3. Import and Export Regulations

6.4. Safety and Operational Guidelines

7. MEA Extrusion Machinery Future Market Size (In USD Mn)

7.1. Future Market Size Projections

7.2. Key Factors Driving Future Market Growth

8. MEA Extrusion Machinery Future Market Segmentation

8.1. By Material (In Value %)

8.2. By Type (In Value %)

8.3. By End-Use Industry (In Value %)

8.4. By Process Type (In Value %)

8.5. By Region (In Value %)

9. MEA Extrusion Machinery Market Analysts Recommendations

9.1. Total Addressable Market (TAM), Serviceable Available Market (SAM), and Serviceable Obtainable Market (SOM) Analysis

9.2. Customer Segmentation and Cohort Analysis

9.3. Strategic Marketing Initiatives

9.4. Identification of White Space Opportunities

Disclaimer Contact UsResearch Methodology

Step 1: Identification of Key Variables

The initial phase involves constructing an ecosystem map encompassing all major stakeholders within the MEA Extrusion Machinery Market. This step is underpinned by extensive desk research, utilizing a combination of secondary and proprietary databases to gather comprehensive industry-level information. The primary objective is to identify and define the critical variables that influence market dynamics.

Step 2: Market Analysis and Construction

In this phase, we will compile and analyze historical data pertaining to the MEA Extrusion Machinery Market. This includes assessing market penetration, the ratio of marketplaces to service providers, and the resultant revenue generation. Furthermore, an evaluation of service quality statistics will be conducted to ensure the reliability and accuracy of the revenue estimates.

Step 3: Hypothesis Validation and Expert Consultation

Market hypotheses will be developed and subsequently validated through computer-assisted telephone interviews (CATIs) with industry experts representing a diverse array of companies. These consultations will provide valuable operational and financial insights directly from industry practitioners, which will be instrumental in refining and corroborating the market data.

Step 4: Research Synthesis and Final Output

The final phase involves direct engagement with multiple extrusion machinery manufacturers to acquire detailed insights into product segments, sales performance, consumer preferences, and other pertinent factors. This interaction will serve to verify and complement the statistics derived from the bottom-up approach, thereby ensuring a comprehensive, accurate, and validated analysis of the MEA Extrusion Machinery market.

Frequently Asked Questions

01. How big is the MEA Extrusion Machinery Market?

The MEA extrusion machinery market is valued at USD 390 million, based on a five-year historical analysis. Additionally, favorable government initiatives that support manufacturing and investments in industrial automation are key drivers.

02. What are the challenges in the MEA Extrusion Machinery Market?

Challenges in MEA extrusion machinery market include high initial capital investment, a shortage of skilled workforce, and fluctuating raw material prices. These factors can hinder the growth and adoption of extrusion machinery in the region.

03. Who are the major players in the MEA Extrusion Machinery Market?

Key players in the MEA extrusion machinery market include KraussMaffei Group, Milacron Holdings Corp., The Japan Steel Works, Ltd., NFM / Welding Engineers, Inc., and Battenfeld-Cincinnati. These companies dominate due to their extensive product portfolios, technological innovations, and strong regional presence.

04. What are the growth drivers of the MEA Extrusion Machinery Market?

The MEA extrusion machinery market is propelled by industrialization and infrastructure development across the MEA region. The rising demand for plastic and metal products, driven by sectors like construction, automotive, and packaging, also contributes significantly to market growth.

Why Buy From Us?

What makes us stand out is that our consultants follows Robust, Refine and Result (RRR) methodology. i.e. Robust for clear definitions, approaches and sanity checking, Refine for differentiating respondents facts and opinions and Result for presenting data with story

We have set a benchmark in the industry by offering our clients with syndicated and customized market research reports featuring coverage of entire market as well as meticulous research and analyst insights.

While we don't replace traditional research, we flip the method upside down. Our dual approach of Top Bottom & Bottom Top ensures quality deliverable by not just verifying company fundamentals but also looking at the sector and macroeconomic factors.

With one step in the future, our research team constantly tries to show you the bigger picture. We help with some of the tough questions you may encounter along the way: How is the industry positioned? Best marketing channel? KPI's of competitors? By aligning every element, we help maximize success.

Our report gives you instant access to the answers and sources that other companies might choose to hide. We elaborate each steps of research methodology we have used and showcase you the sample size to earn your trust.

If you need any support, we are here! We pride ourselves on universe strength, data quality, and quick, friendly, and professional service.