North America Centrifugal Compressor Market Outlook to 2030

Region:North America

Author(s):Shreya

Product Code:KROD8010

December 2024

97

About the Report

North America Centrifugal Compressor Market Overview

- The North America centrifugal compressor market is valued at USD 5.2 billion, based on a five-year historical analysis. This growth is primarily driven by the increasing demand for energy-efficient compression solutions across industries such as oil and gas, power generation, and manufacturing. The shift towards natural gas-based energy and the replacement of coal-based plants have significantly contributed to this market expansion.

- The United States dominates the North American centrifugal compressor market, attributed to its robust industrial sector and substantial investments in oil and gas exploration and production. The presence of extensive infrastructure and continuous technological advancements further solidify its leading position in the market.

- Governments worldwide are implementing stringent emission standards to reduce environmental pollution. These regulations compel industries to adopt cleaner technologies and practices, influencing operational strategies and investments in emission control systems.

North America Centrifugal Compressor Market Segmentation

By Type: The market is segmented by type into single-stage and multi-stage compressors. Multi-stage centrifugal compressors hold a dominant market share due to their ability to handle higher pressure ratios, making them suitable for applications requiring significant compression. Their efficiency and reliability in industrial processes contribute to their widespread adoption.

By Application: The market is further segmented by application into oil & gas, power generation, chemical & petrochemical, manufacturing, and HVAC. The oil & gas sector dominates the market, driven by the extensive use of centrifugal compressors in gas processing, transmission, and refining processes. The continuous exploration and production activities in North America bolster the demand in this segment.

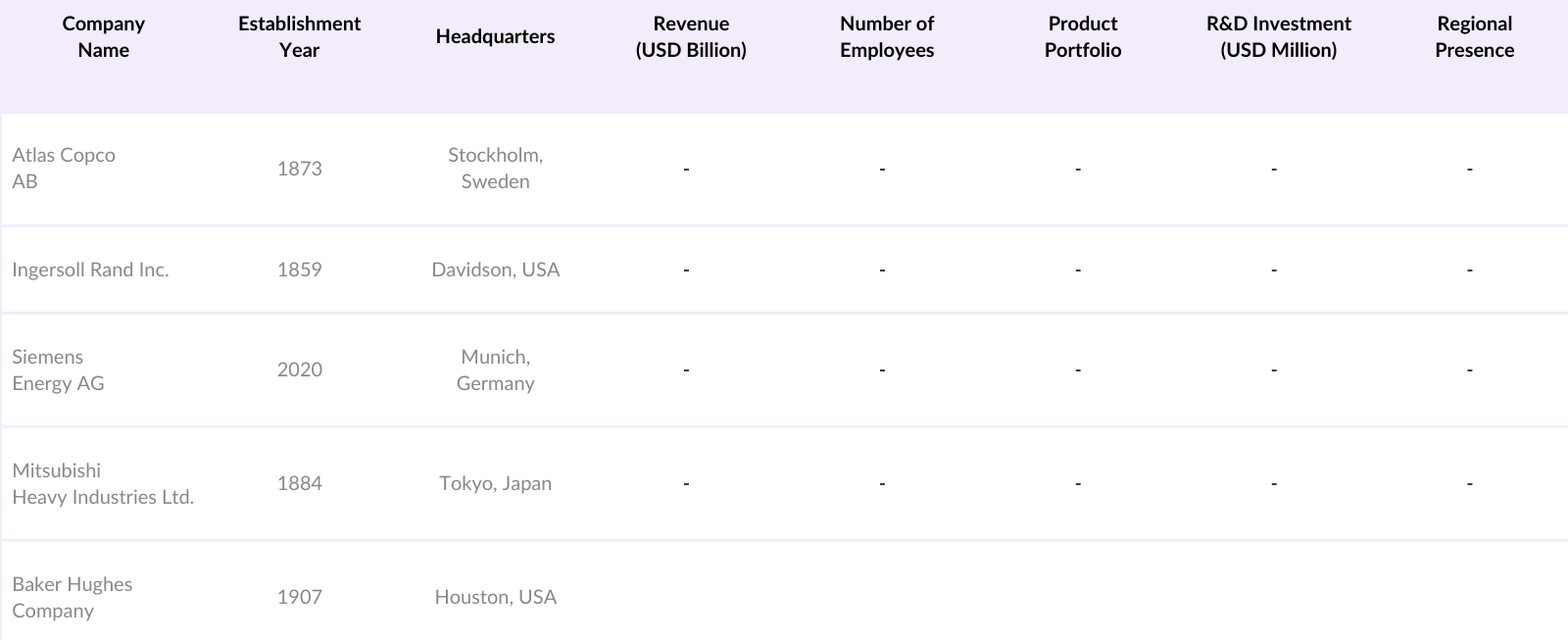

North America Centrifugal Compressor Market Competitive Landscape

The North America centrifugal compressor market is characterized by the presence of several key players who contribute significantly to market dynamics. These companies focus on product innovation, strategic partnerships, and expanding their market presence to maintain a competitive edge.

North America Centrifugal Compressor Industry Analysis

Growth Drivers

- Industrial Expansion: In 2024, the global manufacturing sector has witnessed significant growth, with the United States reporting approximately 12.9 million manufacturing jobs as of June, an increase from 12.7 million in 2022. California leads with 1.3 million manufacturing workers, representing 8.7% of its workforce, followed by Texas with 925,394 employees, accounting for 8.2% of its workforce. This expansion is driven by increased consumer demand and substantial investments in manufacturing infrastructure.

- Energy Efficiency Initiatives: The U.S. Department of Energy's Better Buildings Initiative has led to nearly $22 billion in energy savings since 2011, with partners reducing greenhouse gas emissions by over 220 million metric tons, equivalent to the annual emissions of approximately 29 million homes. In the first half of 2024, more than 40 countries earmarked $290 billion for clean energy support, reflecting a global commitment to energy efficiency.

- Technological Advancements: The adoption of advanced technologies such as robotics, automation, and the Industrial Internet of Things (IIoT) is transforming manufacturing processes. Leading manufacturers are investing in robotics and automation to speed manufacturing and reduce costs, data analytics to improve forecasting and spot supply shortages, and IoT to collect and analyze data from sensors on the factory floor. This technological integration enhances productivity and operational efficiency.

Market Challenges

- High Initial Capital Investment: Implementing advanced manufacturing technologies and energy-efficient systems requires substantial upfront capital. For instance, the construction of new manufacturing facilities in the U.S. has seen significant investment, with annual construction spending in manufacturing standing at $201 billion as of July 2023, representing a 70% year-over-year increase. Such high initial costs can be a barrier for small and medium-sized enterprises.

- Maintenance and Operational Costs: Advanced manufacturing equipment and energy-efficient systems often entail higher maintenance and operational expenses. The complexity of these systems requires specialized skills for upkeep, leading to increased labor costs. Additionally, the integration of new technologies can result in unforeseen operational challenges, further escalating expenses.

North America Centrifugal Compressor Market Future Outlook

Over the next five years, the North America centrifugal compressor market is expected to show significant growth driven by continuous government support, advancements in compressor technology, and increasing demand for energy-efficient solutions across various industries. The emphasis on reducing carbon emissions and the transition towards cleaner energy sources are anticipated to further propel market expansion.

Future Market Opportunities

- Replacement of Aging Infrastructure: Many industrial facilities are operating with outdated infrastructure, leading to inefficiencies and higher operational costs. The U.S. Department of Energy's Better Buildings Initiative has demonstrated that upgrading to energy-efficient systems can result in substantial savings, with partners collectively saving nearly $22 billion through efficiency improvements. This presents a significant opportunity for modernization and cost reduction.

- Integration with IoT and Digitalization: The integration of IoT and digital technologies in manufacturing processes offers opportunities for enhanced efficiency and productivity. Leading manufacturers are investing in data analytics to improve forecasting and spot supply shortages, and IoT to collect and analyze data from sensors on the factory floor. This digital transformation enables real-time monitoring and optimization of operations.

Scope of the Report

|

By Type |

- Single-Stage Centrifugal Compressors |

|

By Application |

- Oil & Gas |

|

By Technology |

- Integrally Geared |

|

By Discharge Pressure |

- Low Pressure (Below 20 Bars) |

|

By Region |

- United States |

Products

Key Target Audience

Oil & Gas Companies

Power Generation Companies

Chemical & Petrochemical Manufacturers

Manufacturing Industries

HVAC System Providers

Government and Regulatory Bodies (e.g., U.S. Department of Energy)

Investors and Venture Capitalist Firms

Environmental Agencies (e.g., Environmental Protection Agency)

Companies

Major Players

Atlas Copco AB

Ingersoll Rand Inc.

Siemens Energy AG

Mitsubishi Heavy Industries Ltd.

Baker Hughes Company

Elliott Group

Howden Group Ltd.

MAN Energy Solutions SE

Gardner Denver Holdings Inc.

Hitachi Ltd.

Kobe Steel Ltd.

FS-Elliott Co., LLC

Sundyne Corporation

IHI Corporation

Kaeser Compressors Inc.

Table of Contents

Market Overview

1.1 Definition and Scope

1.2 Market Taxonomy

1.3 Market Growth Rate

1.4 Market Segmentation Overview

Market Size (In USD Billion)

2.1 Historical Market Size

2.2 Year-On-Year Growth Analysis

2.3 Key Market Developments and Milestones

Market Analysis

3.1 Growth Drivers

3.1.1 Industrial Expansion

3.1.2 Energy Efficiency Initiatives

3.1.3 Technological Advancements

3.1.4 Increasing Natural Gas Production

3.2 Market Challenges

3.2.1 High Initial Capital Investment

3.2.2 Maintenance and Operational Costs

3.2.3 Volatility in Raw Material Prices

3.3 Opportunities

3.3.1 Replacement of Aging Infrastructure

3.3.2 Integration with IoT and Digitalization

3.3.3 Expansion in Emerging Markets

3.4 Trends

3.4.1 Adoption of Magnetic Bearing Technology

3.4.2 Shift Towards Oil-Free Compressors

3.4.3 Emphasis on Sustainable and Green Technologies

3.5 Government Regulations

3.5.1 Emission Standards

3.5.2 Energy Efficiency Policies

3.5.3 Incentives for Clean Energy Adoption

3.6 SWOT Analysis

3.7 Stakeholder Ecosystem

3.8 Porters Five Forces Analysis

3.9 Competitive Landscape

Market Segmentation

4.1 By Type (In Value %)

4.1.1 Single-Stage Centrifugal Compressors

4.1.2 Multi-Stage Centrifugal Compressors

4.2 By Application (In Value %)

4.2.1 Oil & Gas

4.2.2 Power Generation

4.2.3 Chemical & Petrochemical

4.2.4 Manufacturing

4.2.5 HVAC

4.3 By Technology (In Value %)

4.3.1 Integrally Geared

4.3.2 Horizontally Split

4.3.3 Vertically Split

4.4 By Discharge Pressure (In Value %)

4.4.1 Low Pressure (Below 20 Bars)

4.4.2 Medium Pressure (20-100 Bars)

4.4.3 High Pressure (Above 100 Bars)

4.5 By Region (In Value %)

4.5.1 United States

4.5.2 Canada

4.5.3 Mexico

4.5.4 Rest of North America

Competitive Analysis

5.1 Detailed Profiles of Major Companies

5.1.1 Atlas Copco AB

5.1.2 Ingersoll Rand Inc.

5.1.3 Siemens Energy AG

5.1.4 Mitsubishi Heavy Industries Ltd.

5.1.5 Baker Hughes Company

5.1.6 Elliott Group

5.1.7 Howden Group Ltd.

5.1.8 MAN Energy Solutions SE

5.1.9 Gardner Denver Holdings Inc.

5.1.10 Hitachi Ltd.

5.1.11 Kobe Steel Ltd.

5.1.12 FS-Elliott Co., LLC

5.1.13 Sundyne Corporation

5.1.14 IHI Corporation

5.1.15 Kaeser Compressors Inc.

5.2 Cross Comparison Parameters (Revenue, Market Share, Product Portfolio, R&D Investment, Regional Presence, Strategic Initiatives, Number of Employees, Year Established)

5.3 Market Share Analysis

5.4 Strategic Initiatives

5.5 Mergers and Acquisitions

5.6 Investment Analysis

5.7 Venture Capital Funding

5.8 Government Grants

5.9 Private Equity Investments

Regulatory Framework

6.1 Environmental Standards

6.2 Compliance Requirements

6.3 Certification Processes

Future Market Size (In USD Billion)

7.1 Future Market Size Projections

7.2 Key Factors Driving Future Market Growth

Future Market Segmentation

8.1 By Type (In Value %)

8.2 By Application (In Value %)

8.3 By Technology (In Value %)

8.4 By Discharge Pressure (In Value %)

8.5 By Region (In Value %)

Analysts Recommendations

9.1 Total Addressable Market (TAM), Serviceable Available Market (SAM), Serviceable Obtainable Market (SOM) Analysis

9.2 Customer Cohort Analysis

9.3 Marketing Initiatives

9.4 White Space Opportunity Analysis

Disclaimer Contact UsResearch Methodology

Step 1: Identification of Key Variables

The initial phase involves constructing an ecosystem map encompassing all major stakeholders within the North America Centrifugal Compressor Market. This step is underpinned by extensive desk research, utilizing a combination of secondary and proprietary databases to gather comprehensive industry-level information. The primary objective is to identify and define the critical variables that influence market dynamics.

Step 2: Market Analysis and Construction

In this phase, we compile and analyze historical data pertaining to the North America Centrifugal Compressor Market. This includes assessing market penetration, the ratio of marketplaces to service providers, and the resultant revenue generation. Furthermore, an evaluation of service quality statistics is conducted to ensure the reliability and accuracy of the revenue estimates.

Step 3: Hypothesis Validation and Expert Consultation

Market hypotheses are developed and subsequently validated through computer-assisted telephone interviews (CATIs) with industry experts representing a diverse array of companies. These consultations provide valuable operational and financial insights directly from industry practitioners, which are instrumental in refining and corroborating the market data.

Step 4: Research Synthesis and Final Output

The final phase involves direct engagement with multiple compressor manufacturers to acquire detailed insights into product segments, sales performance, consumer preferences, and other pertinent factors. This interaction serves to verify and complement the statistics derived from the bottom-up approach, thereby ensuring a comprehensive, accurate, and validated analysis of the North America Centrifugal Compressor market.

Frequently Asked Questions

How big is the North America Centrifugal Compressor Market?

The North America centrifugal compressor market is valued at USD 5.2 billion, driven by rising demand across industries like oil & gas, power generation, and manufacturing, coupled with a shift towards more energy-efficient technologies.

What are the main drivers of the North America Centrifugal Compressor Market?

Key drivers in the North America centrifugal compressor market include industrial expansion, energy efficiency initiatives, and increased natural gas production, which all create a sustained demand for centrifugal compressors in various industrial applications.

Which sectors dominate the North America Centrifugal Compressor Market?

The oil & gas and power generation sectors are predominant in the North America centrifugal compressor market, as compressors are critical in gas processing, transmission, and power plant operations.

Who are the major players in the North America Centrifugal Compressor Market?

Leading players in the North America centrifugal compressor market include Atlas Copco, Ingersoll Rand, Siemens Energy, Mitsubishi Heavy Industries, and Baker Hughes, known for their innovation, expansive portfolios, and extensive global reach.

What challenges exist in the North America Centrifugal Compressor Market?

Challenges in the North America centrifugal compressor market include high initial capital costs, maintenance expenses, and fluctuating raw material prices, which can impact profitability and market expansion.

Why Buy From Us?

What makes us stand out is that our consultants follows Robust, Refine and Result (RRR) methodology. i.e. Robust for clear definitions, approaches and sanity checking, Refine for differentiating respondents facts and opinions and Result for presenting data with story

We have set a benchmark in the industry by offering our clients with syndicated and customized market research reports featuring coverage of entire market as well as meticulous research and analyst insights.

While we don't replace traditional research, we flip the method upside down. Our dual approach of Top Bottom & Bottom Top ensures quality deliverable by not just verifying company fundamentals but also looking at the sector and macroeconomic factors.

With one step in the future, our research team constantly tries to show you the bigger picture. We help with some of the tough questions you may encounter along the way: How is the industry positioned? Best marketing channel? KPI's of competitors? By aligning every element, we help maximize success.

Our report gives you instant access to the answers and sources that other companies might choose to hide. We elaborate each steps of research methodology we have used and showcase you the sample size to earn your trust.

If you need any support, we are here! We pride ourselves on universe strength, data quality, and quick, friendly, and professional service.