North America CNC Milling Machines Market Outlook to 2030

Region:North America

Author(s):Vijay Kumar

Product Code:KROD2066

November 2024

82

About the Report

North America CNC Milling Machines Market Overview

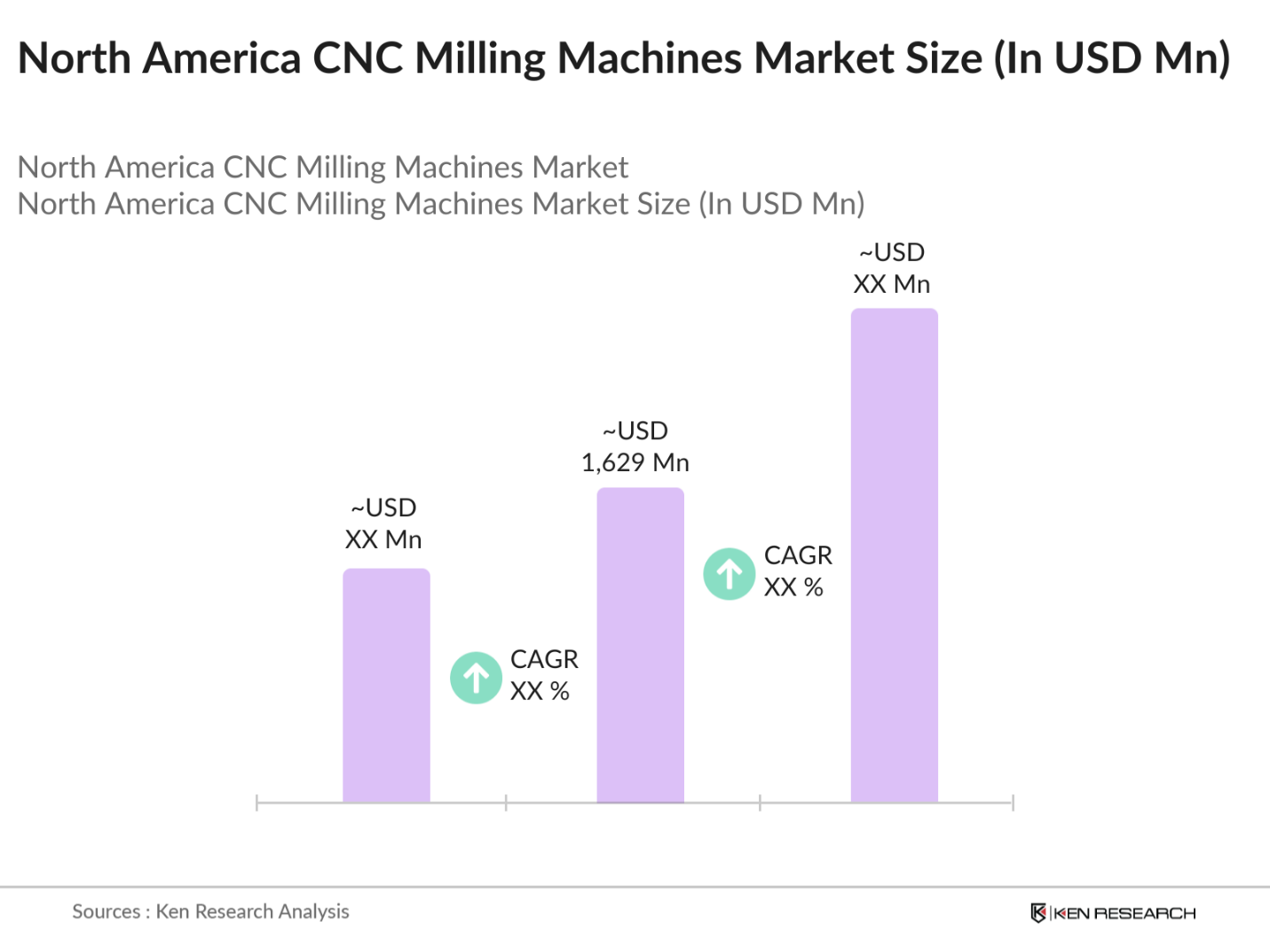

- The North America CNC Milling Machines Market is valued at USD 1,629 million, based on a five-year historical analysis. This growth is driven by the increasing demand for precision engineering in industries such as automotive, aerospace, and electronics. The integration of advanced technologies like automation and IoT has further enhanced production efficiency, contributing to market expansion.

- The United States dominates the North American CNC milling machines market due to its robust manufacturing sector and early adoption of advanced machining technologies. The presence of major automotive and aerospace companies, coupled with substantial investments in R&D, has solidified its leading position. Canada and Mexico also contribute significantly, benefiting from favorable trade agreements and growing industrial activities.

- The transition from the North American Free Trade Agreement (NAFTA) to the United States-Mexico-Canada Agreement (USMCA) in 2020 has impacted the CNC milling machines market. The USMCA includes provisions that affect the sourcing of materials and components, influencing supply chains and manufacturing costs. Manufacturers must navigate these regulations to optimize operations and maintain compliance, affecting strategic decisions in the CNC milling sector.

North America CNC Milling Machines Market Segmentation

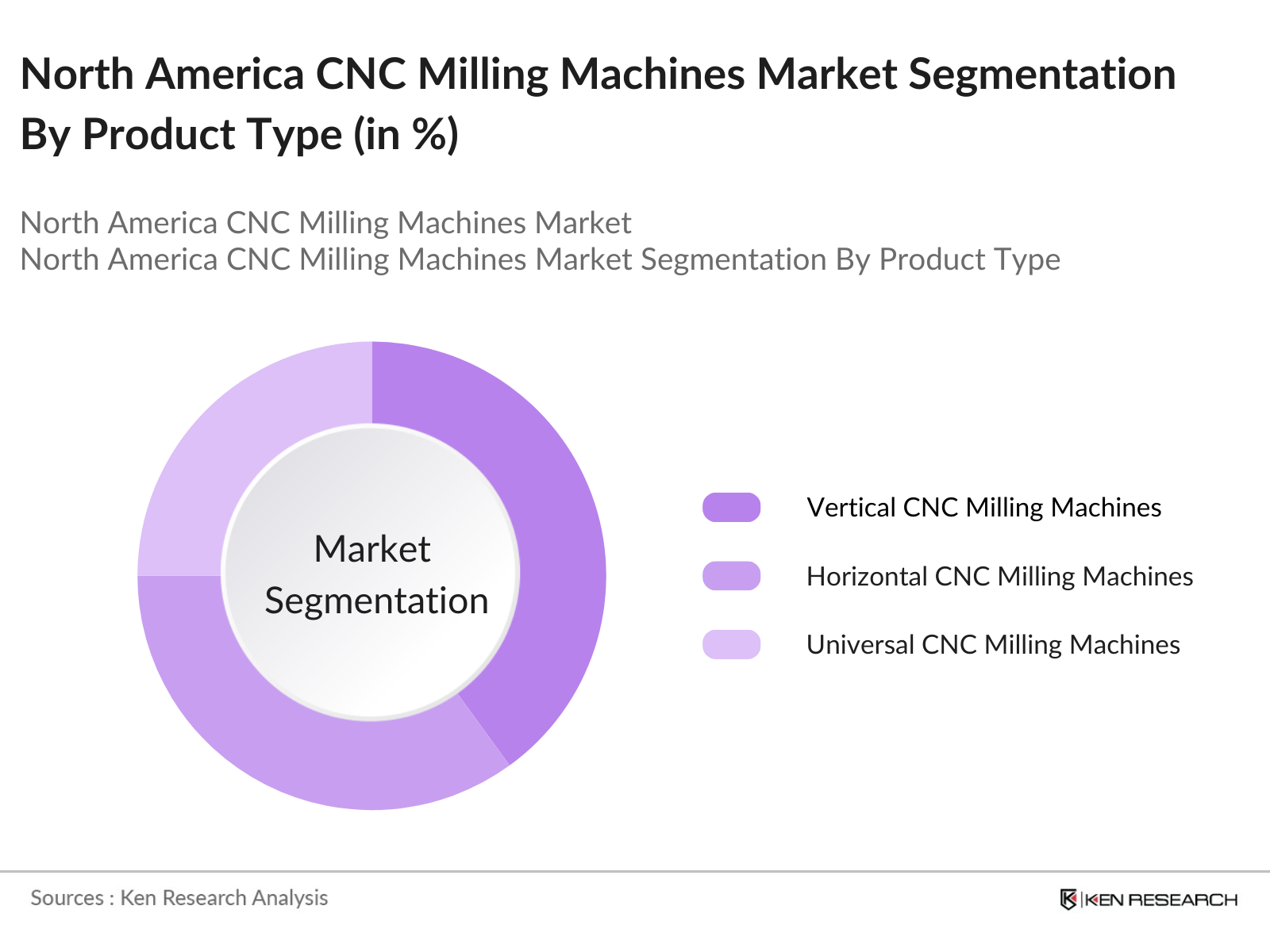

By Product Type: The market is segmented by product type into Vertical CNC Milling Machines, Horizontal CNC Milling Machines, and Universal CNC Milling Machines. Vertical CNC Milling Machines hold a dominant market share due to their versatility and cost-effectiveness, making them suitable for a wide range of applications across various industries. Their ability to handle complex operations with precision has led to widespread adoption.

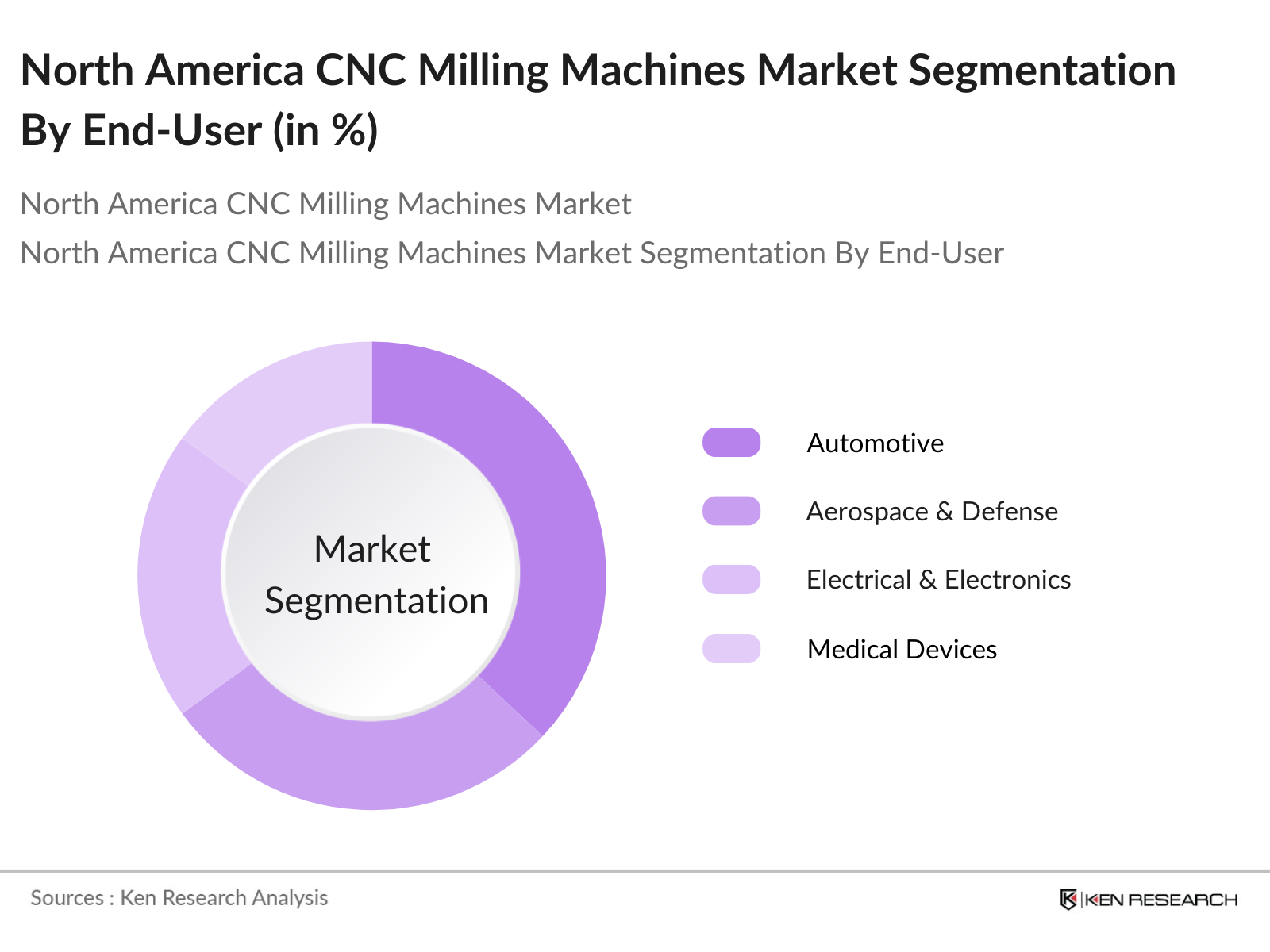

By End-User Industry: The market is also segmented by end-user industry into Automotive, Aerospace & Defense, Electrical & Electronics, Medical Devices, and Others. The Automotive sector leads in market share, driven by the continuous demand for high-precision components and the industry's focus on automation to enhance production efficiency. The need for lightweight and complex parts in modern vehicles has further propelled the adoption of CNC milling machines in this sector.

North America CNC Milling Machines Market Competitive Landscape

The North America CNC Milling Machines Market is characterized by the presence of several key players who contribute to its competitive landscape. These companies are recognized for their technological advancements, extensive product portfolios, and strategic initiatives that drive market growth.

North America CNC Milling Machines Industry Analysis

Growth Drivers

- Technological Advancements in Precision Engineering: The North American manufacturing sector has seen significant technological advancements in precision engineering. In 2023, the U.S. manufacturing industry invested approximately $250 billion in research and development, focusing on enhancing precision machining capabilities. This investment has led to the adoption of advanced CNC milling machines, which are essential for producing complex components with high accuracy.

- Increasing Demand in Aerospace and Automotive Sectors: The aerospace and automotive industries in North America have experienced robust growth, leading to increased demand for CNC milling machines. In 2023, the U.S. aerospace industry generated revenues exceeding $300 billion, with a significant portion allocated to the production of aircraft components requiring precision machining. Similarly, the automotive sector produced over 10 million vehicles in the same year, necessitating the use of CNC milling machines for manufacturing engine parts, transmission systems, and other critical components.

- Shift Toward Industry 4.0 and Automation: North American manufacturers are increasingly adopting Industry 4.0 principles, emphasizing automation and smart manufacturing. In 2023, approximately 60% of manufacturing firms in the U.S. reported implementing automation technologies, including CNC milling machines integrated with IoT devices. This shift aims to enhance productivity, reduce operational costs, and improve product quality. The integration of CNC machines with digital technologies enables real-time monitoring and predictive maintenance, leading to increased efficiency and reduced downtime.

Market Challenges

- Trade and Supply Chain Constraints: Global trade dynamics and supply chain disruptions have impacted the CNC milling machines market in North America. In 2023, supply chain challenges led to delays in the delivery of critical components, extending lead times for CNC machine production by an average of 20%. Additionally, trade policies and tariffs have affected the cost and availability of imported parts, influencing the overall pricing and accessibility of CNC milling machines. These constraints pose challenges to manufacturers and end-users, affecting market stability.

- Skilled Labor Shortage: The North American manufacturing industry faces a notable shortage of skilled labor. In 2023, there were approximately 500,000 unfilled manufacturing positions in the U.S., with a significant portion requiring expertise in operating CNC milling machines. This gap is attributed to an aging workforce and a decline in vocational training programs. The shortage of qualified operators hampers the efficient utilization of CNC technologies, affecting production capabilities and potentially slowing market growth.

North America CNC Milling Machines Market Future Outlook

Over the next five years, the North America CNC Milling Machines Market is expected to show significant growth driven by continuous advancements in machining technologies, increasing demand for precision components, and the integration of automation in manufacturing processes. The adoption of Industry 4.0 practices and the expansion of end-user industries will further propel market expansion.

Market Opportunities

- Growth in Medical Device Manufacturing: The medical device manufacturing sector in North America has expanded significantly. In 2023, the U.S. medical device industry was valued at over $150 billion, with a substantial portion dedicated to the production of precision components. CNC milling machines are essential for manufacturing intricate medical devices such as implants and surgical instruments. The increasing demand for advanced medical devices presents a significant opportunity for the CNC milling machines market, as manufacturers seek to enhance production capabilities to meet industry needs.

- Adoption of IoT-Enabled CNC Machines: The integration of the Internet of Things (IoT) into CNC milling machines offers significant growth potential. In 2023, approximately 35% of CNC machines in North America were IoT-enabled, allowing for real-time monitoring and data analytics. This connectivity facilitates predictive maintenance, reduces downtime, and enhances operational efficiency. The adoption of IoT-enabled CNC machines is expected to increase as manufacturers recognize the benefits of connected systems, presenting opportunities for market expansion.

Scope of the Report

|

Product Type |

Vertical CNC Milling Machines |

|

Axis Type |

3-Axis |

|

End-User Industry |

Automotive |

|

Component Type |

Controllers |

|

Country |

United States |

Products

Key Target Audience

Automotive Manufacturers

Aerospace & Defense Contractors

Electrical & Electronics Companies

Medical Device Manufacturers

Industrial Machinery Suppliers

Precision Engineering Firms

Investment and Venture Capitalist Firms

Government and Regulatory Bodies (e.g., U.S. Department of Commerce, Canadian Ministry of Innovation, Science and Industry)

Companies

Players Mentioned in the Report

Haas Automation, Inc.

Okuma Corporation

DMG MORI Co., Ltd.

Makino Milling Machine Co., Ltd.

Yamazaki Mazak Corporation

Hurco Companies, Inc.

FANUC Corporation

Siemens AG

Mitsubishi Electric Corporation

JTEKT Corporation

Table of Contents

1. Market Overview

1.1 Definition and Scope

1.2 Market Taxonomy

1.3 Market Growth Rate

1.4 Market Segmentation Overview

2. Market Size (In USD Billion)

2.1 Historical Market Size

2.2 Year-On-Year Growth Analysis

2.3 Key Market Developments and Milestones

3. Market Analysis

3.1 Growth Drivers

3.1.1 Technological Advancements in Precision Engineering

3.1.2 Increasing Demand in Aerospace and Automotive Sectors

3.1.3 Shift Toward Industry 4.0 and Automation

3.1.4 Government Support for Manufacturing

3.2 Market Challenges

3.2.1 High Capital and Maintenance Costs

3.2.2 Skilled Labor Shortage

3.2.3 Trade and Supply Chain Constraints

3.3 Opportunities

3.3.1 Growth in Medical Device Manufacturing

3.3.2 Adoption of IoT-Enabled CNC Machines

3.3.3 Expansion into Small and Mid-Sized Enterprises

3.4 Trends

3.4.1 Multi-Axis CNC Machines Popularity

3.4.2 Integration of AI in CNC Systems

3.4.3 Increased Demand for Customization in Manufacturing

3.5 Government Regulations

3.5.1 NAFTA and USMCA Trade Policies

3.5.2 OSHA Standards for Workplace Safety

3.5.3 Environmental Standards on Emissions

3.6 SWOT Analysis

3.7 Stakeholder Ecosystem

3.8 Porters Five Forces Analysis

3.9 Competitive Landscape

4. Market Segmentation

4.1 By Product Type (In Value %)

4.1.1 Vertical CNC Milling Machines

4.1.2 Horizontal CNC Milling Machines

4.1.3 Universal CNC Milling Machines

4.2 By Axis Type (In Value %)

4.2.1 3-Axis

4.2.2 4-Axis

4.2.3 5-Axis

4.2.4 Others

4.3 By End-User Industry (In Value %)

4.3.1 Automotive

4.3.2 Aerospace & Defense

4.3.3 Electrical & Electronics

4.3.4 Medical Devices

4.3.5 Others

4.4 By Component Type (In Value %)

4.4.1 Controllers

4.4.2 Drives

4.4.3 Motors

4.4.4 Others

4.5 By Country (In Value %)

4.5.1 United States

4.5.2 Canada

4.5.3 Mexico

5. Competitive Analysis

5.1 Detailed Profiles of Major Companies

5.1.1 Haas Automation, Inc.

5.1.2 Okuma Corporation

5.1.3 DMG MORI Co., Ltd.

5.1.4 Makino Milling Machine Co., Ltd.

5.1.5 Yamazaki Mazak Corporation

5.1.6 Hurco Companies, Inc.

5.1.7 FANUC Corporation

5.1.8 Siemens AG

5.1.9 Mitsubishi Electric Corporation

5.1.10 JTEKT Corporation

5.1.11 Doosan Machine Tools Co., Ltd.

5.1.12 GF Machining Solutions

5.1.13 EMAG GmbH & Co. KG

5.1.14 Hardinge Inc.

5.1.15 Fives Group

5.2 Cross Comparison Parameters (Number of Employees, Headquarters, Inception Year, Revenue, Product Portfolio, Market Share, R&D Investment, Regional Presence)

5.3 Market Share Analysis

5.4 Strategic Initiatives

5.5 Mergers and Acquisitions

5.6 Investment Analysis

5.7 Venture Capital Funding

5.8 Government Grants

5.9 Private Equity Investments

6. Regulatory Framework

6.1 Industry Standards and Certifications

6.2 Compliance Requirements

6.3 Trade Policies and Tariffs

7. Future Market Size (In USD Billion)

7.1 Future Market Size Projections

7.2 Key Factors Driving Future Market Growth

8. Future Market Segmentation

8.1 By Product Type (In Value %)

8.2 By Axis Type (In Value %)

8.3 By End-User Industry (In Value %)

8.4 By Component Type (In Value %)

8.5 By Country (In Value %)

9. Market Analysts Recommendations

9.1 Total Addressable Market (TAM), Serviceable Available Market (SAM), and Serviceable Obtainable Market (SOM) Analysis

9.2 Customer Cohort Analysis

9.3 Marketing Initiatives

9.4 White Space Opportunity Analysis

Disclaimer Contact UsResearch Methodology

Step 1: Identification of Key Variables

The initial phase involves constructing an ecosystem map encompassing all major stakeholders within the North America CNC Milling Machines Market. This step is underpinned by extensive desk research, utilizing a combination of secondary and proprietary databases to gather comprehensive industry-level information. The primary objective is to identify and define the critical variables that influence market dynamics.

Step 2: Market Analysis and Construction

In this phase, we compile and analyze historical data pertaining to the North America CNC Milling Machines Market. This includes assessing market penetration, the ratio of marketplaces to service providers, and the resultant revenue generation. Furthermore, an evaluation of service quality statistics is conducted to ensure the reliability and accuracy of the revenue estimates.

Step 3: Hypothesis Validation and Expert Consultation

Market hypotheses are developed and subsequently validated through computer-assisted telephone interviews (CATIs) with industry experts representing a diverse array of companies. These consultations provide valuable operational and financial insights directly from industry practitioners, which are instrumental in refining and corroborating the market data.

Step 4: Research Synthesis and Final Output

The final phase involves direct engagement with multiple CNC milling machine manufacturers to acquire detailed insights into product segments, sales performance, consumer preferences, and other pertinent factors. This interaction serves to verify and complement the statistics derived from the bottom-up approach, thereby ensuring a comprehensive, accurate, and validated analysis of the North America CNC Milling Machines Market.

Frequently Asked Questions

01. How big is the North America CNC Milling Machines Market?

The North America CNC Milling Machines Market is valued at USD 1,629 million, based on a five-year historical analysis. This growth is driven by the increasing demand for precision engineering in industries such as automotive, aerospace, and electronics.

02. What are the challenges in the North America CNC Milling Machines Market?

Challenges include high capital and maintenance costs, a shortage of skilled labor, and trade and supply chain constraints.

03. Who are the major players in the North America CNC Milling Machines Market?

Key players in the market include Haas Automation, Inc., Okuma Corporation DMG MORI Co., Ltd., Makino Milling Machine Co., Ltd., and Yamazaki Mazak Corporation. These companies are leaders due to their advanced technology portfolios, extensive R&D investments, and global distribution networks.

04. What drives growth in the North America CNC Milling Machines Market?

The market growth is driven by increasing demand for precision-engineered components in industries like automotive and aerospace, coupled with advancements in automation and the adoption of IoT in manufacturing processes.

Why Buy From Us?

What makes us stand out is that our consultants follows Robust, Refine and Result (RRR) methodology. i.e. Robust for clear definitions, approaches and sanity checking, Refine for differentiating respondents facts and opinions and Result for presenting data with story

We have set a benchmark in the industry by offering our clients with syndicated and customized market research reports featuring coverage of entire market as well as meticulous research and analyst insights.

While we don't replace traditional research, we flip the method upside down. Our dual approach of Top Bottom & Bottom Top ensures quality deliverable by not just verifying company fundamentals but also looking at the sector and macroeconomic factors.

With one step in the future, our research team constantly tries to show you the bigger picture. We help with some of the tough questions you may encounter along the way: How is the industry positioned? Best marketing channel? KPI's of competitors? By aligning every element, we help maximize success.

Our report gives you instant access to the answers and sources that other companies might choose to hide. We elaborate each steps of research methodology we have used and showcase you the sample size to earn your trust.

If you need any support, we are here! We pride ourselves on universe strength, data quality, and quick, friendly, and professional service.