North America Plastic Injection Molding Machine Market Outlook to 2030

Region:North America

Author(s):Vijay Kumar

Product Code:KROD4685

December 2024

99

About the Report

North America Plastic Injection Molding Machine Market Overview

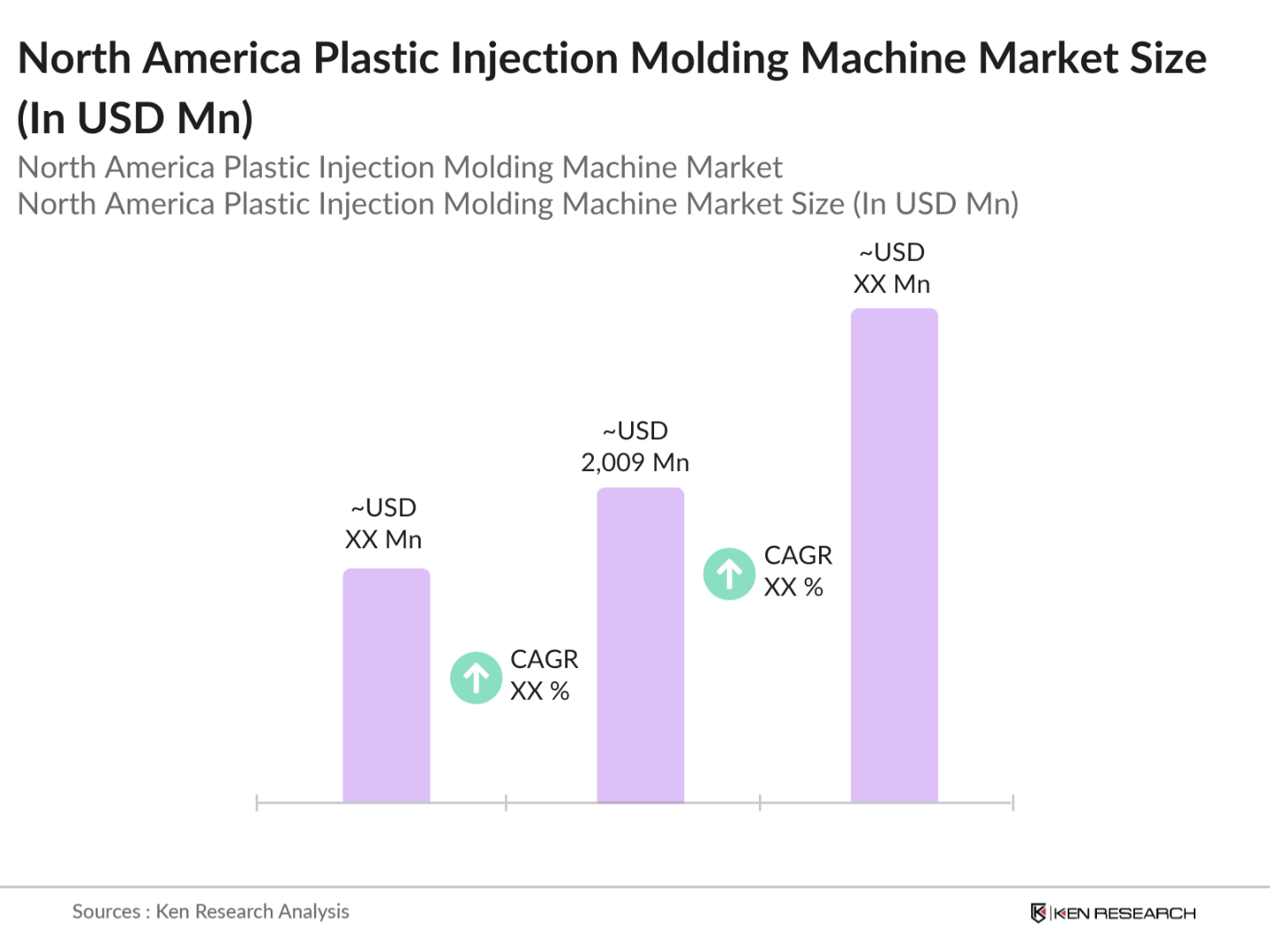

- The North America plastic injection molding machine market is valued at USD 2,009 million, based on a five-year historical analysis. This growth is primarily driven by the increasing adoption of lightweight plastic components across automotive, consumer goods, and healthcare industries. The ongoing transition from metal to plastic components, aimed at enhancing energy efficiency and reducing vehicle weight, is a key factor boosting market expansion. Additionally, the adoption of electric injection molding machines, known for their energy efficiency and precision, is also driving market growth.

- The United States and Canada are the dominant countries in the North American market. The U.S. holds a leading position due to its strong manufacturing base, access to advanced technologies, and the presence of a skilled workforce. Additionally, the U.S. automotive sector significantly drives the demand for plastic injection molding machines, with high-volume production requirements for lightweight components, especially for electric vehicle manufacturing.

- New regulations are being introduced for the use of certain types of plastics in automotive and medical applications. The European Union, for example, has banned the use of specific hazardous chemicals in automotive plastics, affecting production processes and encouraging the use of alternative materials.

North America Plastic Injection Molding Machine Market Segmentation

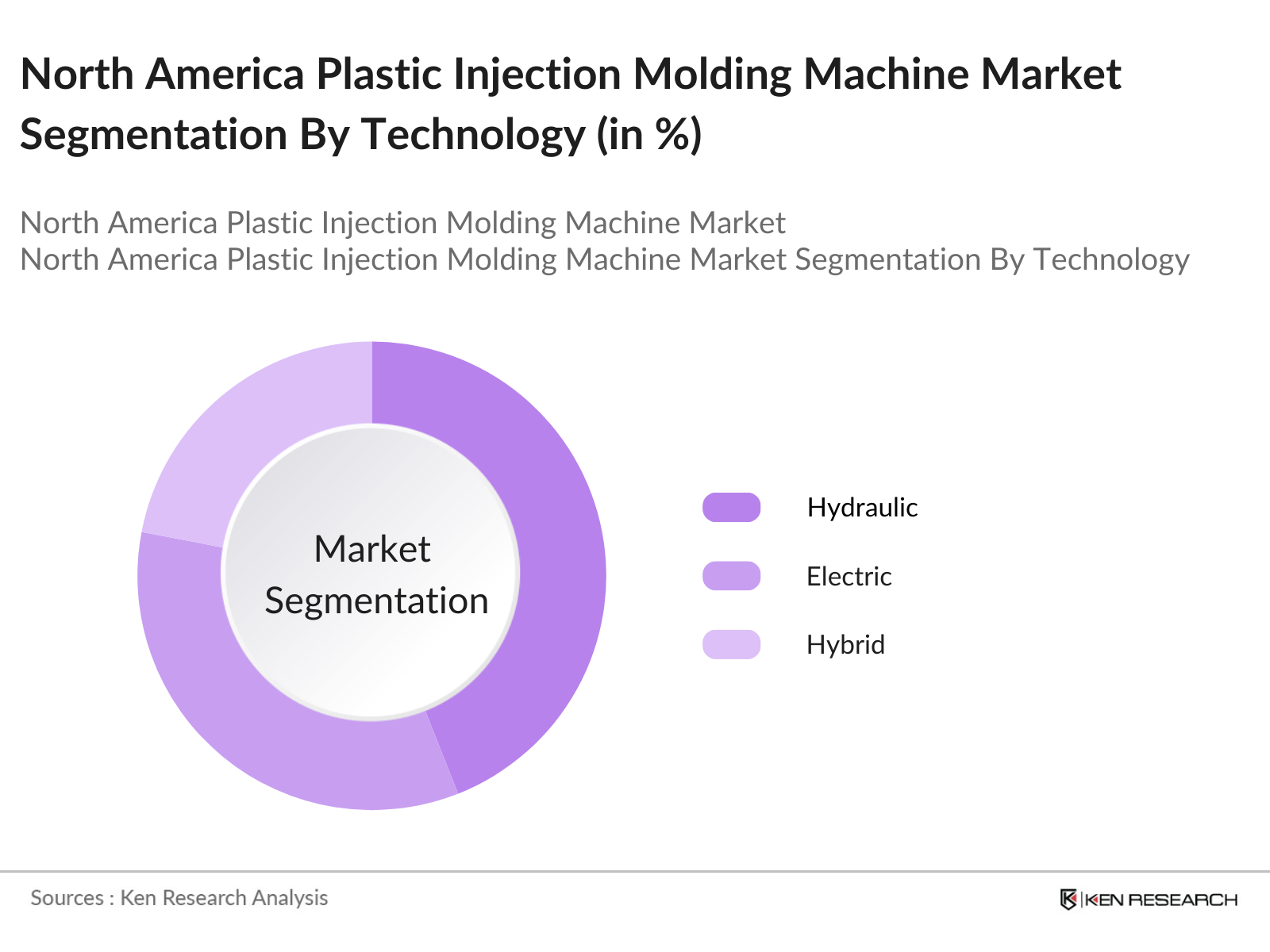

By Technology: The North America plastic injection molding machine market is segmented by technology into hydraulic, electric, and hybrid machines. The hydraulic technology segment holds a dominant market share due to its ability to generate high pressure, making it suitable for manufacturing thick and dense plastic components. Electric injection molding machines are gaining traction owing to their energy efficiency and reduced cycle times. This segment is particularly popular in the automotive industry, where precision and energy efficiency are key considerations.

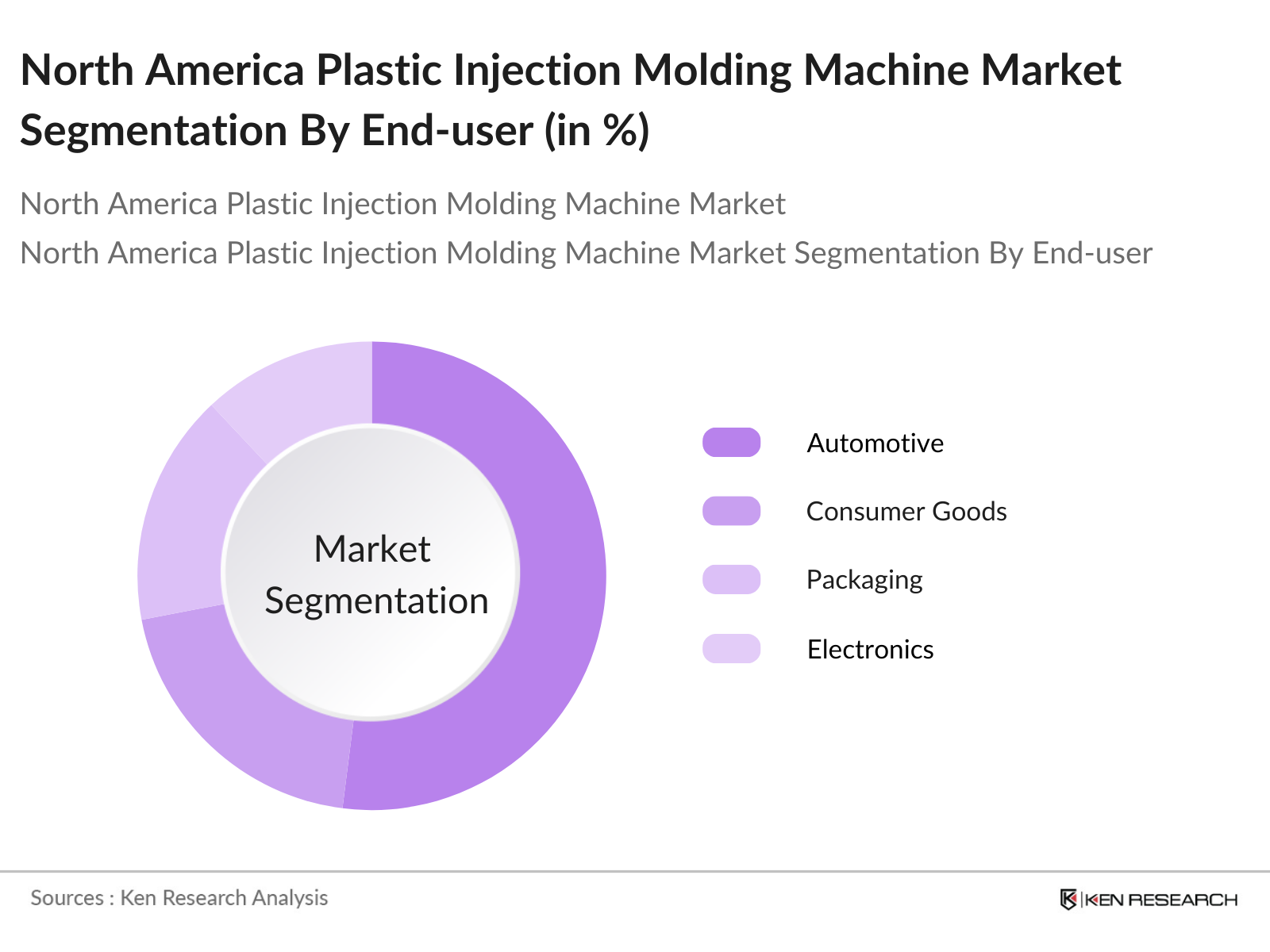

By End-use Industry: The market is further segmented by end-use industry into automotive, consumer goods, packaging, electronics, medical, and others. The automotive segment dominates the market due to the increasing adoption of plastic components in vehicle manufacturing to reduce overall weight and enhance fuel efficiency. The medical segment is also witnessing significant growth, driven by the rising demand for medical devices and disposable medical supplies, which require precision and compliance with stringent quality standards.

North America Plastic Injection Molding Machine Market Competitive Landscape

The North America plastic injection molding machine market is characterized by the presence of key players who influence the industry through product innovation, strategic partnerships, and expansions. The competitive landscape is primarily dominated by global players with significant production capacities and strong distribution networks. The market is led by companies like Engel Machinery and Husky Injection Molding, known for their advanced electric and hybrid machines.

North America Plastic Injection Molding Machine Industry Analysis

Growth Drivers

- Increasing Industrialization: Industrialization has continued to expand globally, with a 3.2% growth rate projected for the world economy in 2024. Manufacturing industries, particularly in emerging markets such as India and China, are seeing robust activity. India is expected to achieve a GDP growth of 5.9% in 2024, while Chinas growth is estimated at 5.0% during the same period. The increased focus on heavy industrial production and infrastructure development in these regions is driving this trend. Global trade growth is recovering, expected to reach 3.25% annually in 2024 and 2025, aligning closely with GDP growth.

- Rising Demand for Precision-Engineered Components: The demand for precision-engineered components has risen significantly due to advancements in automation and manufacturing technologies. This demand is primarily fueled by growth in the automotive, aerospace, and electronics industries. For instance, automotive manufacturing in the Euro Area is expected to recover, growing by 1.5% in 2024, following a period of stagnation. This increase is linked to the growing production of lightweight components aimed at meeting regulatory standards for fuel efficiency.

- Expansion of Automotive Sector (Increased Lightweight Component Manufacturing): The automotive sector's focus on reducing vehicle weight to enhance fuel efficiency and meet stringent emissions standards has driven the need for lightweight materials such as aluminum and advanced plastics. In the United States, automotive production is expected to grow by 2.0% in 2024. This growth is supported by increased investments in hybrid and electric vehicle manufacturing, which demand more precision-engineered lightweight components.

Market Challenges

- High Initial Investment Costs: The capital-intensive nature of setting up new manufacturing facilities, especially those that incorporate advanced technologies like automation and IIoT (Industrial Internet of Things), poses a challenge. For instance, the cost of industrial machinery has increased by 4% in 2024 due to supply chain disruptions and increased raw material prices. This rise in costs is making it difficult for new entrants and smaller companies to invest in such technologies.

- Complex Technological Integration: Integrating new technologies, such as AI and IoT, into traditional manufacturing setups has proven challenging due to compatibility issues and the need for upskilling the workforce. Advanced economies are struggling to maintain technological momentum, with growth in technology integration slowing to 1.7% in 2024. This slowdown is a result of gaps in digital infrastructure and a lack of skilled personnel.

North America Plastic Injection Molding Machine Market Future Outlook

Over the next few years, the North America plastic injection molding machine market is expected to show steady growth driven by the rising demand for advanced plastic components across various industries. The automotive and healthcare sectors, in particular, will continue to play a crucial role in the market expansion due to the increasing production of lightweight vehicle components and medical disposables.

Market Opportunities

- Integration of Automation and IIoT in Manufacturing: The adoption of automation and IIoT in manufacturing processes presents a significant opportunity for improving efficiency and reducing operational costs. Emerging markets are capitalizing on this trend, with countries like India and China investing heavily in smart manufacturing. Chinas industrial production growth is projected to be 5.4% in 2024, supported by government initiatives aimed at modernizing its manufacturing sector.

- Adoption of Eco-friendly Materials and Technologies: With increasing environmental regulations, there is a growing need for the adoption of eco-friendly materials and sustainable manufacturing practices. This shift is driving investment in the development of bio-based plastics and green manufacturing technologies. In 2024, approximately 15% of new manufacturing facilities in the United States are expected to incorporate eco-friendly technologies, reflecting the shift towards sustainability.

Scope of the Report

|

Technology |

Hydraulic Electric Hybrid |

|

Technological Sophistication |

High Tech Mid Tech Low Tech |

|

Clamping Force |

<100 Metric Tons 101 to 400 Metric Tons 401 to 1000 Metric Tons, >1000 Metric Tons |

|

End-use |

Automotive Consumer Goods Packaging Electronics Medical Others |

|

Region |

U.S. Canada |

Products

Key Target Audience

Automotive Manufacturers

Medical Device Manufacturers

Packaging Solutions Providers

Electronics Manufacturers

Consumer Goods Manufacturers

Investment and Venture Capitalist Firms

Government and Regulatory Bodies (e.g., U.S. Environmental Protection Agency, Health Canada)

Industrial Equipment Suppliers

Companies

Players Mentioned in the Report

Engel Machinery Inc.

Husky Injection Molding Systems Ltd.

Milacron LLC

ARBURG GmbH

Nissei America, Inc.

Haitian International Holdings Ltd.

Sumitomo (SHI) Demag Plastics Machinery

KraussMaffei Group

Wittmann Battenfeld, Inc.

JSW Plastics Machinery Inc.

Table of Contents

1. North America Plastic Injection Molding Machine Market Overview

1.1. Definition and Scope

1.2. Market Taxonomy (By Technology, Clamping Force, Technological Sophistication, End-Use)

1.3. Market Growth Rate

1.4. Market Segmentation Overview

2. North America Plastic Injection Molding Machine Market Size (USD Million)

2.1. Historical Market Size

2.2. Market Size by Technology (Hydraulic, Electric, Hybrid)

2.3. Market Size by Clamping Force (<100, 101-400, 401-1000, >1000 Metric Tons)

2.4. Market Size by End-Use (Automotive, Consumer Goods, Packaging, Electronics, Medical)

3. North America Plastic Injection Molding Machine Market Analysis

3.1. Growth Drivers

3.1.1. Rising Adoption of Electric Vehicles (Automotive Sector)

3.1.2. Expansion of Medical Device Manufacturing (Medical Sector)

3.1.3. Demand for Lightweight Components in Consumer Electronics

3.2. Market Challenges

3.2.1. High Initial Costs of Electric Machines

3.2.2. Availability of Raw Materials

3.3. Opportunities

3.3.1. Adoption of Hybrid Machines for Versatile Applications

3.3.2. Growth in Sustainable Plastic Manufacturing Technologies

3.4. Trends

3.4.1. Integration of IIoT (Industrial Internet of Things) in Injection Molding

3.4.2. Shift Towards Energy-Efficient Solutions

3.5. Regulatory Framework

3.5.1. Environmental Regulations on Plastic Manufacturing

3.5.2. Standards for Medical Grade Plastic Components

3.6. Porters Five Forces Analysis

3.7. Competitive Landscape and SWOT Analysis

4. North America Plastic Injection Molding Machine Market Segmentation

4.1. By Technology

4.1.1. Hydraulic

4.1.2. Electric

4.1.3. Hybrid

4.2. By Technological Sophistication

4.2.1. High Tech

4.2.2. Mid Tech

4.2.3. Low Tech

4.3. By Clamping Force

4.3.1. <100 Metric Tons

4.3.2. 101 to 400 Metric Tons

4.3.3. 401 to 1000 Metric Tons

4.3.4. >1000 Metric Tons

4.4. By End-Use

4.4.1. Automotive

4.4.2. Consumer Goods

4.4.3. Packaging

4.4.4. Electronics

4.4.5. Medical

4.4.6. Others

4.5. By Region

4.5.1. U.S.

4.5.2. Canada

5. North America Plastic Injection Molding Machine Market Competitive Analysis

5.1. Detailed Profiles of Major Companies

5.1.1. Milacron LLC

5.1.2. Husky Injection Molding Systems Ltd.

5.1.3. ARBURG GmbH + Co KG

5.1.4. Sumitomo (SHI) Demag

5.1.5. Engel Machinery Inc.

5.1.6. Toshiba Machine Co., Ltd.

5.1.7. Haitian International Holdings Limited

5.1.8. Nissei Plastic Industrial Co., Ltd.

5.1.9. JSW Plastics Machinery Inc.

5.1.10. KraussMaffei Group GmbH

5.1.11. Wittmann Battenfeld GmbH

5.1.12. Negri Bossi S.p.A

5.1.13. FANUC Corporation

5.1.14. Ube Industries, Ltd.

5.1.15. Huarong Plastic Machinery Co., Ltd.

5.2. Cross Comparison Parameters (No. of Employees, Revenue, Market Share, R&D Spending)

5.3. Market Share Analysis

5.4. Strategic Initiatives and Partnerships

5.5. Recent Developments and Innovations

6. North America Plastic Injection Molding Machine Market Regulatory Framework

6.1. Compliance Requirements

6.2. Certification Processes

6.3. Industry Standards

7. North America Plastic Injection Molding Machine Future Market Size

7.1. Future Market Size Projections (By Value and Volume)

7.2. Key Factors Driving Future Market Growth

8. North America Plastic Injection Molding Machine Future Market Segmentation

8.1. By Technology

8.2. By Clamping Force

8.3. By Technological Sophistication

8.4. By End-Use

8.5. By Region

9. North America Plastic Injection Molding Machine Market Analysts Recommendations

9.1. TAM/SAM/SOM Analysis

9.2. Customer Cohort Analysis

9.3. White Space Opportunity Analysis

9.4. Strategic Positioning and Recommendations

Disclaimer Contact UsResearch Methodology

Step 1: Identification of Key Variables

The initial phase involves constructing an ecosystem map of the North America Plastic Injection Molding Machine Market. This process includes extensive desk research, utilizing a combination of proprietary and external databases to gather comprehensive information on the market's key dynamics.

Step 2: Market Analysis and Construction

In this phase, historical data pertaining to market size, penetration rates, and market saturation is compiled and analyzed. An evaluation of production statistics will be conducted to ensure the accuracy of the data.

Step 3: Hypothesis Validation and Expert Consultation

Market hypotheses are formulated and validated through direct interviews with industry experts. These consultations provide valuable operational insights and industry best practices.

Step 4: Research Synthesis and Final Output

The final phase involves synthesizing the research findings and verifying the market statistics through direct engagement with multiple manufacturers, ensuring a comprehensive and accurate analysis of the market.

Frequently Asked Questions

01. How big is the North America Plastic Injection Molding Machine Market?

The North America plastic injection molding machine market is valued at USD 2,009 million, based on a five-year historical analysis. This growth is primarily driven by the increasing adoption of lightweight plastic components across automotive, consumer goods, and healthcare industries.

02. What are the growth drivers of the North America Plastic Injection Molding Machine Market?

Key drivers include the adoption of electric vehicles, demand for cost-efficient plastic packaging solutions, and advancements in injection molding technology that reduce production costs.

03. Who are the major players in the North America Plastic Injection Molding Machine Market?

Major players include Engel Machinery Inc., Husky Injection Molding Systems Ltd., ARBURG GmbH, and Sumitomo (SHI) Demag Plastics Machinery.

04. What are the challenges in the North America Plastic Injection Molding Machine Market?

Challenges include high initial investment costs, fluctuating raw material prices, and complex maintenance requirements of advanced machinery.

Why Buy From Us?

What makes us stand out is that our consultants follows Robust, Refine and Result (RRR) methodology. i.e. Robust for clear definitions, approaches and sanity checking, Refine for differentiating respondents facts and opinions and Result for presenting data with story

We have set a benchmark in the industry by offering our clients with syndicated and customized market research reports featuring coverage of entire market as well as meticulous research and analyst insights.

While we don't replace traditional research, we flip the method upside down. Our dual approach of Top Bottom & Bottom Top ensures quality deliverable by not just verifying company fundamentals but also looking at the sector and macroeconomic factors.

With one step in the future, our research team constantly tries to show you the bigger picture. We help with some of the tough questions you may encounter along the way: How is the industry positioned? Best marketing channel? KPI's of competitors? By aligning every element, we help maximize success.

Our report gives you instant access to the answers and sources that other companies might choose to hide. We elaborate each steps of research methodology we have used and showcase you the sample size to earn your trust.

If you need any support, we are here! We pride ourselves on universe strength, data quality, and quick, friendly, and professional service.