North America Polyester Film Market Outlook to 2030

Region:North America

Author(s):Shreya Garg

Product Code:KROD7464

December 2024

90

About the Report

North America Polyester Film Market Overview

- The North America polyester film market, valued at USD 9.9 billion, is driven by high demand across various sectors including packaging, electronics, and industrial applications. Polyester film is highly sought after for its durability, strength, and barrier properties, making it an essential material in flexible packaging for food and beverages. The increasing trend towards sustainable packaging, coupled with advancements in polyester film manufacturing technology, has significantly boosted demand. This market growth has been solidified over a five-year historical analysis, establishing a strong foundation for continued adoption of polyester film in diverse applications.

- In North America, the United States is the dominant country in the polyester film market due to its advanced manufacturing infrastructure and high demand from key industries like electronics, packaging, and solar energy. Major cities, including Los Angeles, Houston, and Chicago, play pivotal roles as manufacturing hubs, offering substantial demand for polyester film across various sectors. Canada and Mexico also contribute to regional demand, primarily due to their growing investments in packaging and industrial film applications.

- North American environmental agencies have established stringent standards for plastic production, focusing on reducing carbon emissions and pollution. The U.S. EPA requires manufacturers to comply with the Greenhouse Gas Reporting Program, which increased its carbon threshold requirements by 10% in 2024. This standard compels polyester film manufacturers to adopt cleaner technologies to minimize environmental impact.

North America Polyester Film Market Segmentation

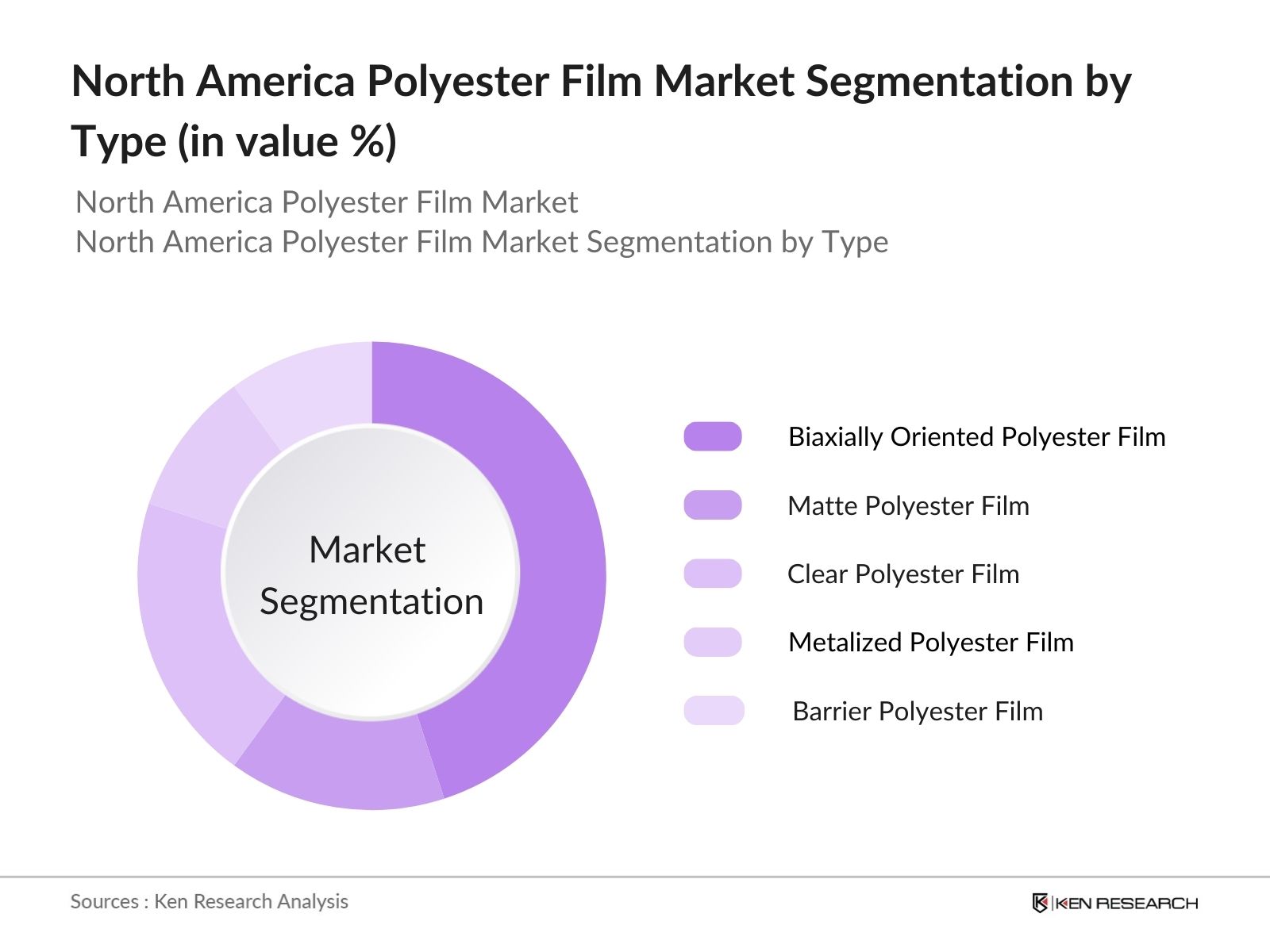

By Type: The market is segmented by type into biaxially oriented polyester (BOPET) film, matte polyester film, clear polyester film, metalized polyester film, and barrier polyester film. Biaxially oriented polyester film leads this segment, largely because of its widespread usage in applications that demand high tensile strength, clarity, and barrier protection. These properties make BOPET film essential in packaging, electrical insulation, and lamination, where durability and clarity are key. This segment has maintained its dominance due to its reliability and strong performance across a variety of industrial and consumer-facing applications.

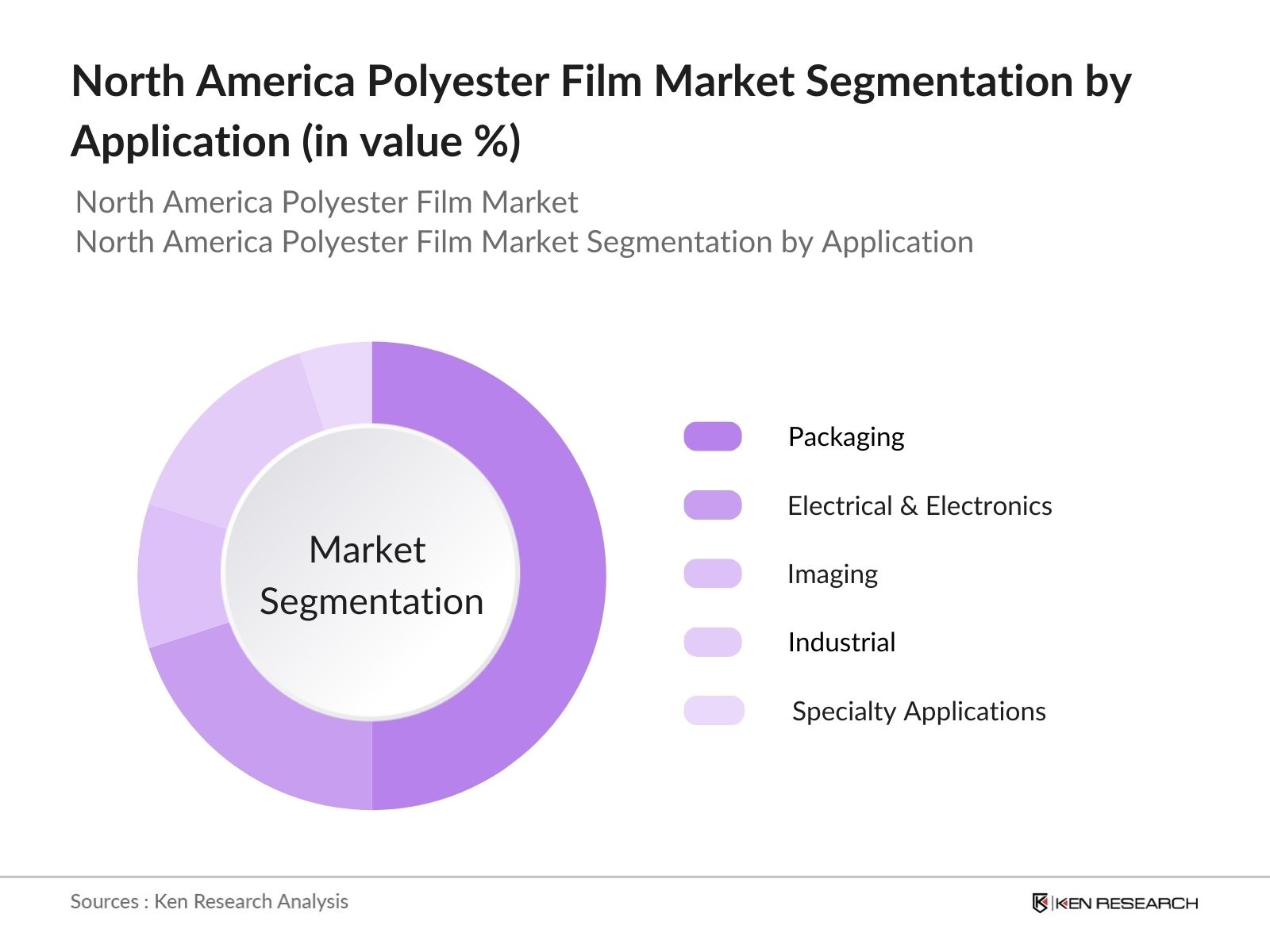

By Application: The application segmentation of the market includes packaging, electrical and electronics, imaging, industrial, and specialty applications. Packaging is the largest application, driven by the increasing demand for flexible packaging materials in food, beverage, and pharmaceutical sectors. Polyester film is favored for packaging applications because of its resistance to moisture, gases, and chemicals, which helps maintain the freshness and safety of packaged goods. This attribute, coupled with its recyclability, has made polyester film the preferred choice for sustainable packaging initiatives in North America.

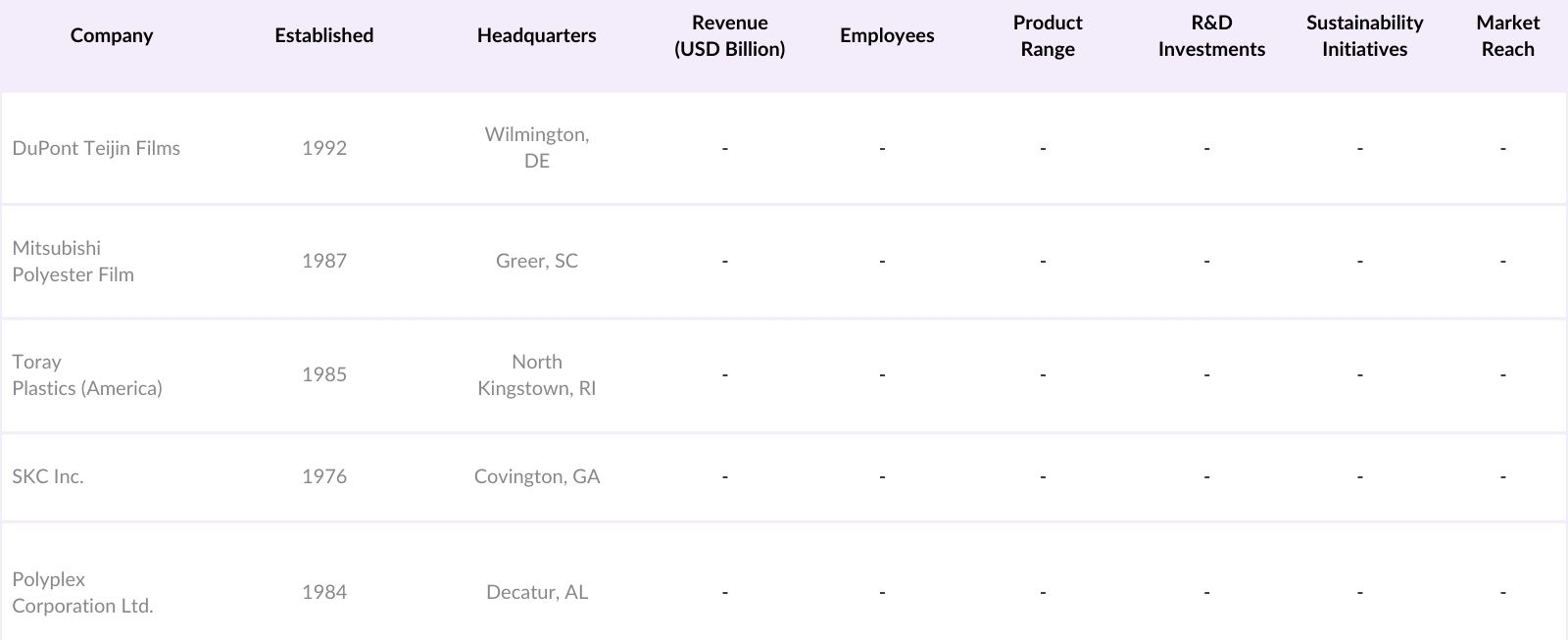

North America Polyester Film Market Competitive Landscape

The North America polyester film market is characterized by the presence of both global and regional players. These companies have established strong market positions through advanced production capabilities, extensive distribution networks, and strategic investments in research and development. This consolidation of key players allows them to influence market dynamics significantly, especially within the packaging and electronics sectors.

North America Polyester Film Industry Analysis

Growth Drivers

- High Demand in Packaging Industry: Polyester films are increasingly used in North Americas packaging industry due to their durability and transparency. The food and beverage sector is a significant driver, with the U.S. alone producing over 13 billion metric tons of food packaging annually in 2024, fueling demand for high-performance films. Packaging innovations have spiked, with government data noting a 20% increase in industry investments into flexible packaging from 2022-2024, driven by polyesters resistance to moisture and gas permeation. This rise aligns with the North American trend toward minimizing food waste, where polyester film's barrier properties play a crucial role.

- Technological Advancements in Film Production: Technological advancements, particularly in coating and extrusion, have propelled the polyester film market in North America. The U.S. Patent and Trademark Office recorded 450 new patents related to film technologies from 2022-2024, signaling rapid innovation in polymer processing. These advancements improve the film's resilience and suitability for high-performance applications across various sectors, including automotive and electronics. Additionally, the U.S. governments Advanced Manufacturing Program earmarked over $300 million for polymer manufacturing research, emphasizing support for high-tech production solutions in polyester films.

- Increasing Application in Solar Panels: North America's solar panel installations hit a milestone of 25 gigawatts in 2024, with polyester films becoming an essential component in the solar industry due to their thermal stability and resistance to environmental stressors. The film acts as an encapsulant to protect photovoltaic cells, particularly in areas exposed to high UV radiation. The U.S. Department of Energy reported a 15% increase in investment in solar film technologies over the past two years, underscoring the growing role of polyester films in renewable energy solutions.

Market Challenges

- Volatility in Raw Material Prices: Polyester film production is heavily reliant on petroleum-based feedstocks, making it vulnerable to price fluctuations in crude oil. Crude oil prices in 2024 averaged $95 per barrel, a substantial increase compared to previous years, according to the U.S. Energy Information Administration. This price volatility directly affects production costs for polyester films, challenging manufacturers to maintain profit margins while meeting increasing demand. Consequently, this raw material dependency raises concerns about the markets long-term stability.

- Regulatory Compliance Costs: Meeting environmental regulations presents a financial burden for North American polyester film manufacturers. The U.S. Environmental Protection Agency (EPA) has introduced stricter emissions guidelines for industrial production, with penalties for non-compliance increasing by 12% since 2023. Compliance with these regulations requires companies to invest in advanced waste management systems and emissions control technologies, elevating operating costs and affecting profit margins. Manufacturers must navigate these costs while maintaining competitive pricing.

North America Polyester Film Market Future Outlook

The North America polyester film market is set to experience steady growth, supported by increasing demand for sustainable and high-performance packaging solutions. Rising adoption in electronics and industrial applications, especially with advancements in thin-film technology, is likely to expand polyester film usage. Moreover, the growing consumer preference for recyclable packaging materials will drive market growth, as companies are encouraged to meet stringent sustainability standards in response to regulatory and consumer pressures.

Future Market Opportunities

- Expansion in Food & Beverage Sector: With North Americas food and beverage sector poised for growth, the demand for high-barrier polyester films is set to increase. In 2024, U.S. food and beverage sales reached $1.4 trillion, necessitating enhanced packaging solutions that can extend shelf life and prevent contamination. Polyester films, known for their barrier properties, are well-suited to meet these demands, providing a significant opportunity for market expansion within this sector.

- Emerging Demand in Electrical Insulation: The electrical industry in North America, valued at $110 billion in 2024, increasingly utilizes polyester films in insulation applications due to their dielectric strength and thermal stability. Polyesters properties align well with the requirements of high-voltage insulation, contributing to its growing adoption. Government-backed projects, including the U.S. Grid Modernization Initiative, emphasize improved materials for electrical components, creating a favorable market environment for polyester films in insulation applications.

Scope of the Report

|

Type |

Biaxially Oriented Polyester (BOPET) Film Matte Polyester Film Clear Polyester Film Metalized Polyester Film Barrier Polyester Film |

|

Application |

Packaging Electrical & Electronics Imaging Industrial Specialty Applications |

|

Thickness |

Thin-Gauge Film Thick-Gauge Film |

|

End-Use Industry |

Food & Beverage Pharmaceutical Automotive Solar Energy Printing |

|

Region |

United States Canada Mexico |

Products

Key Target Audience

Polyester Film Manufacturers

Packaging Industry Players

Automotive Component Suppliers

Electronics and Electrical Manufacturers

Solar Panel Producers

Investors and Venture Capitalist Firms

Government and Regulatory Bodies (Environmental Protection Agency, Food and Drug Administration)

Research and Development Institutions

Companies

Major Players

DuPont Teijin Films

Mitsubishi Polyester Film

Toray Plastics (America)

SKC Inc.

Polyplex Corporation Ltd.

Avery Dennison Corporation

Flex Films (USA) Inc.

Ester Industries Ltd.

Celanese Corporation

Uflex Ltd.

Nan Ya Plastics Corporation

Garware Polyester Ltd.

Sumilon Polyester Films Pvt. Ltd.

Jindal Poly Films Ltd.

3M Company

Table of Contents

North America Polyester Film Market Overview

1.1. Definition and Scope

1.2. Market Taxonomy

1.3. Market Growth Rate

1.4. Market Segmentation Overview

North America Polyester Film Market Size (In USD Mn)

2.1. Historical Market Size

2.2. Year-On-Year Growth Analysis

2.3. Key Market Developments and Milestones

North America Polyester Film Market Analysis

3.1. Growth Drivers

3.1.1. Rising Demand in Packaging Industry

3.1.2. Technological Advancements in Film Processing

3.1.3. Increasing Use in Electrical Insulation

3.1.4. Expansion in Solar Panel Applications

3.2. Market Challenges

3.2.1. Fluctuating Raw Material Prices

3.2.2. Environmental Regulations

3.2.3. Availability of Alternatives

3.3. Opportunities

3.3.1. Growth in Flexible Electronics

3.3.2. Eco-friendly and Biodegradable Variants

3.3.3. Collaborations with End-User Industries

3.4. Trends

3.4.1. Increased Adoption of Recyclable Films

3.4.2. Integration with Sustainable Packaging Solutions

3.4.3. Advancements in Coating Technologies

3.5. Government Regulation

3.5.1. Packaging and Labeling Standards

3.5.2. Environmental Protection Acts

3.5.3. Trade Tariffs and Import/Export Policies

3.5.4. Safety Regulations for Electrical Applications

3.6. SWOT Analysis

3.7. Stakeholder Ecosystem

3.8. Porters Five Forces Analysis

3.9. Competitive Ecosystem

North America Polyester Film Market Segmentation

4.1. By Product Type (In Value %)

4.1.1. Biaxially Oriented Polyester (BOPET) Film

4.1.2. Coated Polyester Film

4.1.3. Metallized Polyester Film

4.1.4. Laminated Polyester Film

4.2. By Application (In Value %)

4.2.1. Packaging

4.2.2. Electrical Insulation

4.2.3. Solar Panels

4.2.4. Imaging and Printing

4.2.5. Industrial Applications

4.3. By End-Use Industry (In Value %)

4.3.1. Food and Beverage

4.3.2. Electronics

4.3.3. Healthcare

4.3.4. Automotive

4.3.5. Construction

4.4. By Thickness (In Value %)

4.4.1. Below 50 Microns

4.4.2. 50-100 Microns

4.4.3. 100-200 Microns

4.4.4. Above 200 Microns

4.5. By Region (In Value %)

4.5.1. United States

4.5.2. Canada

4.5.3. Mexico

North America Polyester Film Market Competitive Analysis

5.1. Detailed Profiles of Major Companies

5.1.1. Toray Industries, Inc.

5.1.2. DuPont Teijin Films

5.1.3. Mitsubishi Polyester Film, Inc.

5.1.4. SKC Co., Ltd.

5.1.5. Polyplex Corporation Limited

5.1.6. Flex Films (USA) Inc.

5.1.7. Jindal Poly Films Ltd.

5.1.8. Terphane

5.1.9. Uflex Ltd.

5.1.10. Ester Industries Ltd.

5.1.11. Garware Polyester Ltd.

5.1.12. Kolon Industries, Inc.

5.1.13. Toyobo Co., Ltd.

5.1.14. Cosmo Films Ltd.

5.1.15. SRF Limited

5.2. Cross Comparison Parameters (No. of Employees, Headquarters, Inception Year, Revenue, R&D Investments, Market Share, Product Portfolio, Key Partnerships)

5.3. Market Share Analysis

5.4. Strategic Initiatives

5.5. Mergers and Acquisitions

5.6. Investment Analysis

5.7. Venture Capital Funding

5.8. Government Grants

5.9. Private Equity Investments

North America Polyester Film Market Regulatory Framework

6.1. Packaging Standards and Requirements

6.2. Environmental Compliance Regulations

6.3. Certifications and Quality Norms

North America Polyester Film Market Future Market Size (In USD Mn)

7.1. Key Factors Influencing Future Growth

7.2. Innovations Impacting Future Demand

North America Polyester Film Future Market Segmentation

8.1. By Product Type (In Value %)

8.2. By Application (In Value %)

8.3. By End-Use Industry (In Value %)

8.4. By Thickness (In Value %)

8.5. By Region (In Value %)

North America Polyester Film Market Analysts Recommendations

9.1. TAM/SAM/SOM Analysis

9.2. Customer Cohort Analysis

9.3. Strategic Marketing Initiatives

9.4. White Space Opportunity Analysis

Research Methodology

Step 1: Identification of Key Variables

The research process begins with mapping the entire ecosystem of the North America Polyester Film Market, identifying all key stakeholders, including manufacturers, suppliers, and end-users. Extensive secondary research, including industry reports and government databases, is conducted to define key market variables.

Step 2: Market Analysis and Construction

Historical data on polyester film production, demand, and consumption patterns are analyzed to establish a comprehensive market framework. This includes assessing penetration rates across sectors, with a focus on identifying revenue trends and the major drivers for each application area.

Step 3: Hypothesis Validation and Expert Consultation

Initial hypotheses about market dynamics are validated through direct consultation with industry experts and stakeholders. Computer-assisted telephone interviews (CATIs) are used to capture insights from professionals, including corporate executives, distributors, and end-users in the industry.

Step 4: Research Synthesis and Final Output

Data from primary and secondary sources are synthesized to create an in-depth analysis of the market, including validation from key manufacturers in North America. The final report is structured to provide actionable insights, enabling stakeholders to make informed business decisions.

Frequently Asked Questions

01. How big is the North America Polyester Film Market?

The North America polyester film market is valued at USD 9.9 billion, driven by increasing applications across packaging, electrical insulation, and imaging industries.

02. What are the challenges in the North America Polyester Film Market?

Challenges in the North America polyester film market include the volatility in raw material prices, stringent regulatory standards, and competition from alternative packaging materials, all of which impact profit margins and market expansion.

03. Who are the major players in the North America Polyester Film Market?

Leading companies in the North America polyester film market include DuPont Teijin Films, Mitsubishi Polyester Film, Toray Plastics, SKC Inc., and Polyplex Corporation Ltd., which dominate due to their extensive product portfolios and strong distribution networks.

04. What are the growth drivers of the North America Polyester Film Market?

Key growth drivers in the North America polyester film market include the demand for durable packaging solutions, the increasing use of polyester films in electronics, and consumer interest in sustainable materials with high recyclability.

05. Which segments dominate the North America Polyester Film Market?

The biaxially oriented polyester film segment dominates the North America polyester film market, particularly within flexible packaging, due to its excellent barrier properties and strength suitable for high-performance applications.

Why Buy From Us?

What makes us stand out is that our consultants follows Robust, Refine and Result (RRR) methodology. i.e. Robust for clear definitions, approaches and sanity checking, Refine for differentiating respondents facts and opinions and Result for presenting data with story

We have set a benchmark in the industry by offering our clients with syndicated and customized market research reports featuring coverage of entire market as well as meticulous research and analyst insights.

While we don't replace traditional research, we flip the method upside down. Our dual approach of Top Bottom & Bottom Top ensures quality deliverable by not just verifying company fundamentals but also looking at the sector and macroeconomic factors.

With one step in the future, our research team constantly tries to show you the bigger picture. We help with some of the tough questions you may encounter along the way: How is the industry positioned? Best marketing channel? KPI's of competitors? By aligning every element, we help maximize success.

Our report gives you instant access to the answers and sources that other companies might choose to hide. We elaborate each steps of research methodology we have used and showcase you the sample size to earn your trust.

If you need any support, we are here! We pride ourselves on universe strength, data quality, and quick, friendly, and professional service.