USA Aerospace Parts Manufacturing Market Outlook to 2030

Region:North America

Author(s):Naman Rohilla

Product Code:KROD10844

December 2024

83

About the Report

USA Aerospace Parts Manufacturing Market Overview

- The USA Aerospace Parts Manufacturing Market is valued at USD 424.3 billion, supported by steady growth in defense and commercial aviation manufacturing. This valuation, based on historical analysis, reflects increased investments in advanced materials and technology innovations across aerospace manufacturing. The growth is further fueled by the United States governments emphasis on strengthening defense capabilities and rising commercial aviation demand due to the increasing frequency of domestic and international travel.

- Leading regions in the USA Aerospace Parts Manufacturing Market include California and Texas, primarily due to the presence of major aerospace manufacturers, suppliers, and defense contractors. These states are hubs for research and development, with established infrastructures supporting high-volume production, robust supply chains, and close proximity to major airline clients and military facilities, which ensures streamlined operations and supply chain efficiency.

- The FAA enforces stringent safety and production standards within the aerospace industry. The FAA has issued over 2,500 safety directives as of 2023, with strict compliance requirements impacting manufacturing processes and material choices. These regulations ensure that aerospace components meet high safety and quality standards, critical for both commercial and defense applications.

USA Aerospace Parts Manufacturing Market Segmentation

- By Product Type: The market is segmented by product type into engine components, airframe parts, landing gear, avionics, and cabin interiors. Engine components hold a dominant share within this segment due to the critical role they play in aircraft performance and safety. The demand for efficient, lightweight, and high-performance engines continues to drive the need for advanced materials and manufacturing processes, making this sub-segment indispensable in aerospace manufacturing.

- By Material Type: The market is segmented by material type into metals (aluminum, titanium), composites, alloys, and plastics and others. Composites dominate this segment due to their lightweight properties and strength, which are critical for enhancing fuel efficiency and overall aircraft performance. The shift towards composites in both commercial and military aircraft is driven by a need for cost reduction and enhanced durability, making them a preferred choice among aerospace manufacturers.

USA Aerospace Parts Manufacturing Market Competitive Landscape

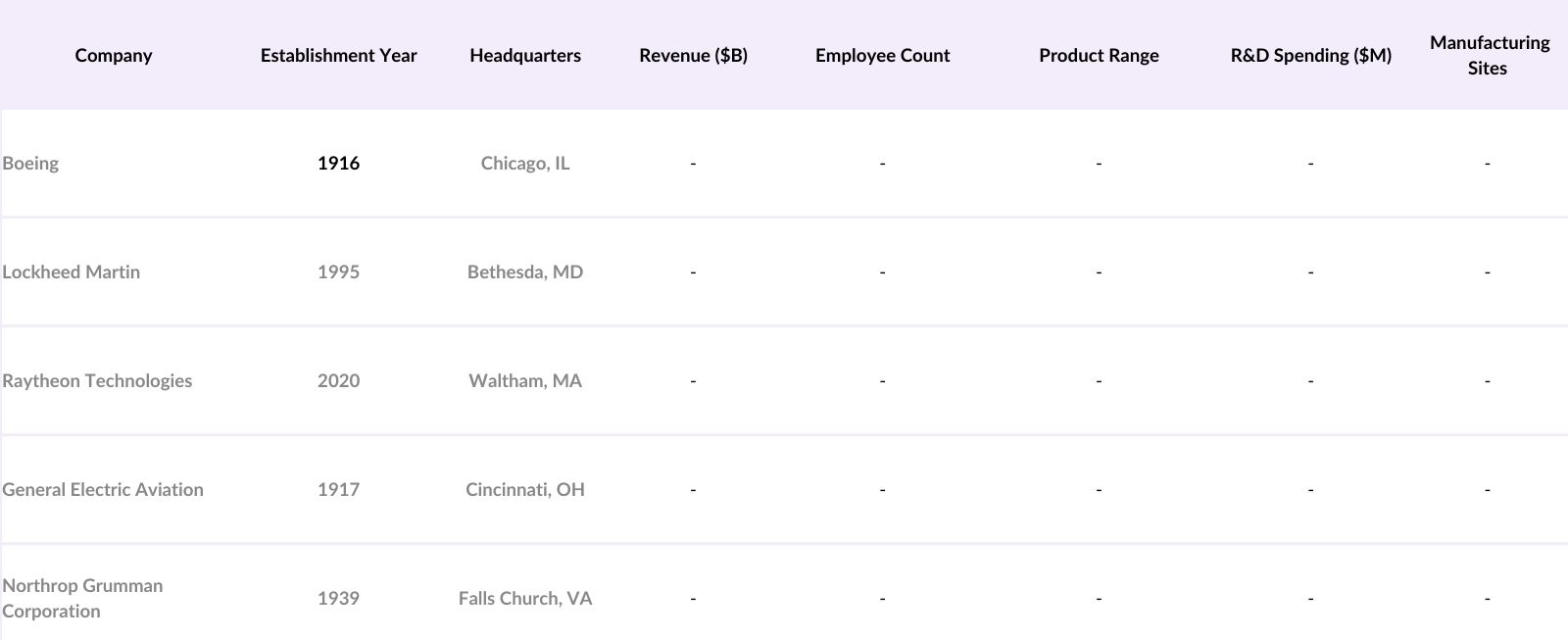

The USA Aerospace Parts Manufacturing Market is dominated by several key players, which are essential to the industrys consolidation and growth due to their established networks and advancements in manufacturing. Prominent companies include Boeing, Lockheed Martin, and Raytheon, all of which have cemented their positions through robust supply chains, government contracts, and continuous innovation.

USA Aerospace Parts Manufacturing Market Analysis

Market Growth Drivers

- Rise in Commercial Aviation Demand: The USA has seen growth in passenger air travel in recent years, driven by increasing consumer and business travel demand. The Bureau of Transportation Statistics reported that U.S. airlines carried over 1 billion passengers in 2023, a notable recovery post-pandemic. This rise in air travel is driving demand for aircraft manufacturing and parts production, which are critical in supporting fleet expansions and replacements. Furthermore, commercial aircraft orders from American-based airlines have surged, with major companies planning to acquire over 2,000 aircraft by 2025 to meet passenger capacity needs.

- Advancements in Material Technology: Material technology advancements, especially in alloys and composites, have become integral to aerospace manufacturing in the U.S. Titanium and composite materials, which offer superior strength and reduced weight, are increasingly used in aircraft components. The National Institute of Standards and Technology (NIST) highlighted that U.S. research investments in advanced materials technology grew by $1.5 billion between 2022 and 2024, focusing on enhancing efficiency and performance in aerospace applications. This trend supports the production of lighter, more fuel-efficient aircraft components essential for sustainability goals.

- Defense Sector Investments: U.S. defense spending, a major growth driver in the aerospace parts market, reached $850 billion in 2024, with increased allocations toward aerospace innovations. According to the U.S. Department of Defense, substantial investments in modernizing and expanding aerial fleets, such as the $12 billion budget for unmanned aerial systems and next-generation fighter jets, have led to increased demand for aerospace parts manufacturing, ensuring production scalability in support of national defense.

Market Challenges

- Raw Material Price Volatility: The aerospace industry has been impacted by fluctuations in the cost of key raw materials like aluminum, titanium, and carbon fiber. According to the U.S. Geological Survey, titanium prices have seen a steady increase, reaching $13,200 per metric ton in 2024 due to supply chain constraints and increased demand. This volatility in raw material prices adds uncertainty and financial pressure on aerospace parts manufacturers, affecting profit margins.

- Supply Chain Disruptions: Supply chain disruptions, aggravated by geopolitical tensions and post-pandemic recovery phases, have severely impacted the aerospace sector. The U.S. Census Bureau noted a 15% increase in lead times for aerospace components in 2023, with delays in shipping critical parts impacting production schedules. This has forced manufacturers to seek alternative suppliers or shift to local sourcing, often at higher costs.

USA Aerospace Parts Manufacturing Market Future Outlook

The USA Aerospace Parts Manufacturing Market is projected to experience substantial growth over the next five years. Factors such as government investments in defense, advancements in aerospace materials, and increased commercial aviation demand are expected to propel the market. The focus on lightweight, durable materials and adoption of Industry 4.0 technologies in manufacturing processes are poised to shape the market landscape further, ensuring sustained innovation and market expansion.

Market Opportunities

- Technological Innovations in 3D Printing: 3D printing technology, which allows for faster and cost-effective production of complex parts, is gaining traction in the aerospace sector. According to the Federal Aviation Administration (FAA), 3D-printed aerospace parts have reduced production time by about 50% for certain components in 2023, thereby enhancing manufacturing efficiency and flexibility. The growth in 3D printing applications aligns with the industry's aim to produce lighter, customized parts with enhanced structural integrity.

- Increased Demand for Lightweight Components: As fuel efficiency becomes a priority, there is an increasing demand for lightweight materials in aerospace parts manufacturing. Reports from the U.S. Department of Energy indicate that the use of lightweight composite materials reduces fuel consumption by up to 15%. In 2023, the U.S. aerospace industry invested around $800 million in research to advance the use of such materials, enabling manufacturers to meet stringent fuel efficiency standards.

Scope of the Report

|

Segments |

Sub-segments |

|

Product Type |

Engine Components Airframe Parts Landing Gear Avionics Cabin Interiors |

|

Material Type |

Metals (Aluminum, Titanium) Composites Alloys Plastics Others |

|

Application |

Commercial Aviation Military Aviation Business and General Aviation Space |

|

Manufacturing Process |

Machining, Casting Forging Additive Manufacturing |

|

Region |

Northeast Midwest South West |

Products

Key Target Audience

Aerospace Manufacturers

Defense Contractors

Investor and Venture Capitalist Firms

Government and Regulatory Bodies (e.g., Federal Aviation Administration)

Aerospace Parts Suppliers

Research and Development Institutions

Material Suppliers

OEM and Aftermarket Service Providers

Companies

Players Mentioned in the Report

Boeing Company

Lockheed Martin Corporation

Raytheon Technologies Corporation

General Electric Aviation

Northrop Grumman Corporation

Honeywell Aerospace

Spirit AeroSystems

Textron Aviation

Parker Hannifin Corporation

Safran SA

Table of Contents

1. USA Aerospace Parts Manufacturing Market Overview

1.1 Definition and Scope

1.2 Market Taxonomy

1.3 Market Growth Rate (Domestic Production, Export and Import Statistics)

1.4 Market Segmentation Overview

2. USA Aerospace Parts Manufacturing Market Size (In USD Bn)

2.1 Historical Market Size

2.2 Year-On-Year Growth Analysis

2.3 Key Market Developments and Milestones

3. USA Aerospace Parts Manufacturing Market Analysis

3.1 Growth Drivers

3.1.1 Rise in Commercial Aviation Demand

3.1.2 Advancements in Material Technology

3.1.3 Defense Sector Investments

3.1.4 Government Support and Incentives

3.2 Market Challenges

3.2.1 Raw Material Price Volatility

3.2.2 Supply Chain Disruptions

3.2.3 Skilled Labor Shortage

3.3 Opportunities

3.3.1 Technological Innovations in 3D Printing

3.3.2 Increased Demand for Lightweight Components

3.3.3 Mergers and Acquisitions

3.4 Trends

3.4.1 Adoption of Composite Materials

3.4.2 Emphasis on Environmental Sustainability

3.4.3 Growth in Aftermarket Services

3.5 Government Regulations

3.5.1 Federal Aviation Administration Standards

3.5.2 Export Compliance and Trade Regulations

3.5.3 Environmental Compliance

3.6 SWOT Analysis

3.7 Supply Chain Ecosystem

3.8 Porters Five Forces Analysis

3.9 Competitor Ecosystem

4. USA Aerospace Parts Manufacturing Market Segmentation

4.1 By Product Type (In Value %)

4.1.1 Engine Components

4.1.2 Airframe Parts

4.1.3 Landing Gear

4.1.4 Avionics

4.1.5 Cabin Interiors

4.2 By Material Type (In Value %)

4.2.1 Metals (Aluminum, Titanium)

4.2.2 Composites

4.2.3 Alloys

4.2.4 Plastics and Others

4.3 By Application (In Value %)

4.3.1 Commercial Aviation

4.3.2 Military Aviation

4.3.3 Business and General Aviation

4.3.4 Space

4.4 By Manufacturing Process (In Value %)

4.4.1 Machining

4.4.2 Casting

4.4.3 Forging

4.4.4 Additive Manufacturing

4.5 By Region (In Value %)

4.5.1 Northeast

4.5.2 Midwest

4.5.3 South

4.5.4 West

5. USA Aerospace Parts Manufacturing Market Competitive Analysis

5.1 Detailed Profiles of Major Companies

5.1.1 Boeing Company

5.1.2 Lockheed Martin Corporation

5.1.3 Raytheon Technologies Corporation

5.1.4 General Electric Aviation

5.1.5 Northrop Grumman Corporation

5.1.6 Honeywell Aerospace

5.1.7 Spirit AeroSystems

5.1.8 Textron Aviation

5.1.9 Parker Hannifin Corporation

5.1.10 Safran SA

5.1.11 Collins Aerospace

5.1.12 Rolls-Royce Holdings

5.1.13 Precision Castparts Corp.

5.1.14 Triumph Group

5.1.15 L3Harris Technologies Inc.

5.2 Cross Comparison Parameters (Revenue, Number of Employees, Headquarters, Product Offerings, Market Reach, Production Capacity, R&D Investment, Customer Segments)

5.3 Market Share Analysis

5.4 Strategic Initiatives

5.5 Mergers and Acquisitions

5.6 Investment Analysis

5.7 Venture Capital Funding

5.8 Government Grants

5.9 Private Equity Investments

6. USA Aerospace Parts Manufacturing Market Regulatory Framework

6.1 Aviation Safety Standards

6.2 Environmental Compliance Requirements

6.3 Export Control and ITAR Compliance

6.4 Certification Processes

7. USA Aerospace Parts Manufacturing Future Market Size (In USD Bn)

7.1 Future Market Size Projections

7.2 Key Factors Driving Future Market Growth

8. USA Aerospace Parts Manufacturing Future Market Segmentation

8.1 By Product Type (In Value %)

8.2 By Material Type (In Value %)

8.3 By Application (In Value %)

8.4 By Manufacturing Process (In Value %)

8.5 By Region (In Value %)

9. USA Aerospace Parts Manufacturing Market Analysts Recommendations

9.1 TAM/SAM/SOM Analysis

9.2 Customer Cohort Analysis

9.3 Marketing Initiatives

9.4 White Space Opportunity Analysis

Disclaimer Contact UsResearch Methodology

Step 1: Identification of Key Variables

In the initial stage, the core variables within the USA Aerospace Parts Manufacturing Market were identified, encompassing all major stakeholders. Extensive desk research and industry-level data analysis were conducted to establish a foundational understanding of the market dynamics and influencing factors.

Step 2: Market Analysis and Construction

Historical data were analyzed to assess market penetration, revenue generation, and production ratios. This step involved an in-depth evaluation of manufacturing capacities and service quality to develop reliable market projections.

Step 3: Hypothesis Validation and Expert Consultation

Market assumptions were validated through consultations with industry experts using computer-assisted telephone interviews (CATIs). Insights from these interviews with industry professionals contributed to refining the market estimations and provided real-world insights into operational dynamics.

Step 4: Research Synthesis and Final Output

The final stage included direct engagement with aerospace parts manufacturers to gather data on product segments, production volumes, and market trends. This step ensured the comprehensive validation and accuracy of the market analysis and provided a complete understanding of the USA Aerospace Parts Manufacturing Market.

Frequently Asked Questions

1. How big is the USA Aerospace Parts Manufacturing Market?

The USA Aerospace Parts Manufacturing Market is valued at USD 424.3 billion, driven by high demand for both commercial and defense aerospace parts, supported by advancements in materials and manufacturing technologies.

2. What are the challenges in the USA Aerospace Parts Manufacturing Market?

Key challenges include the volatility of raw material prices, labor shortages, and complex regulatory compliance requirements. These factors impact production costs and supply chain efficiency.

3. Who are the major players in the USA Aerospace Parts Manufacturing Market?

Major players include Boeing Company, Lockheed Martin Corporation, Raytheon Technologies, General Electric Aviation, and Northrop Grumman. These companies maintain dominance due to extensive production facilities, strong R&D investments, and government contracts.

4. What drives the growth of the USA Aerospace Parts Manufacturing Market?

Growth drivers include increased demand for lightweight, high-performance components in commercial aviation and heightened defense spending by the government. The adoption of new materials and manufacturing technologies also plays a major role.

Why Buy From Us?

What makes us stand out is that our consultants follows Robust, Refine and Result (RRR) methodology. i.e. Robust for clear definitions, approaches and sanity checking, Refine for differentiating respondents facts and opinions and Result for presenting data with story

We have set a benchmark in the industry by offering our clients with syndicated and customized market research reports featuring coverage of entire market as well as meticulous research and analyst insights.

While we don't replace traditional research, we flip the method upside down. Our dual approach of Top Bottom & Bottom Top ensures quality deliverable by not just verifying company fundamentals but also looking at the sector and macroeconomic factors.

With one step in the future, our research team constantly tries to show you the bigger picture. We help with some of the tough questions you may encounter along the way: How is the industry positioned? Best marketing channel? KPI's of competitors? By aligning every element, we help maximize success.

Our report gives you instant access to the answers and sources that other companies might choose to hide. We elaborate each steps of research methodology we have used and showcase you the sample size to earn your trust.

If you need any support, we are here! We pride ourselves on universe strength, data quality, and quick, friendly, and professional service.