USA Fiber Reinforced Polymer (FRP) Market Outlook to 2030

Region:North America

Author(s):Shambhavi Awasthi

Product Code:KROD8115

January 2025

87

About the Report

USA Fiber Reinforced Polymer (FRP) Market Overview

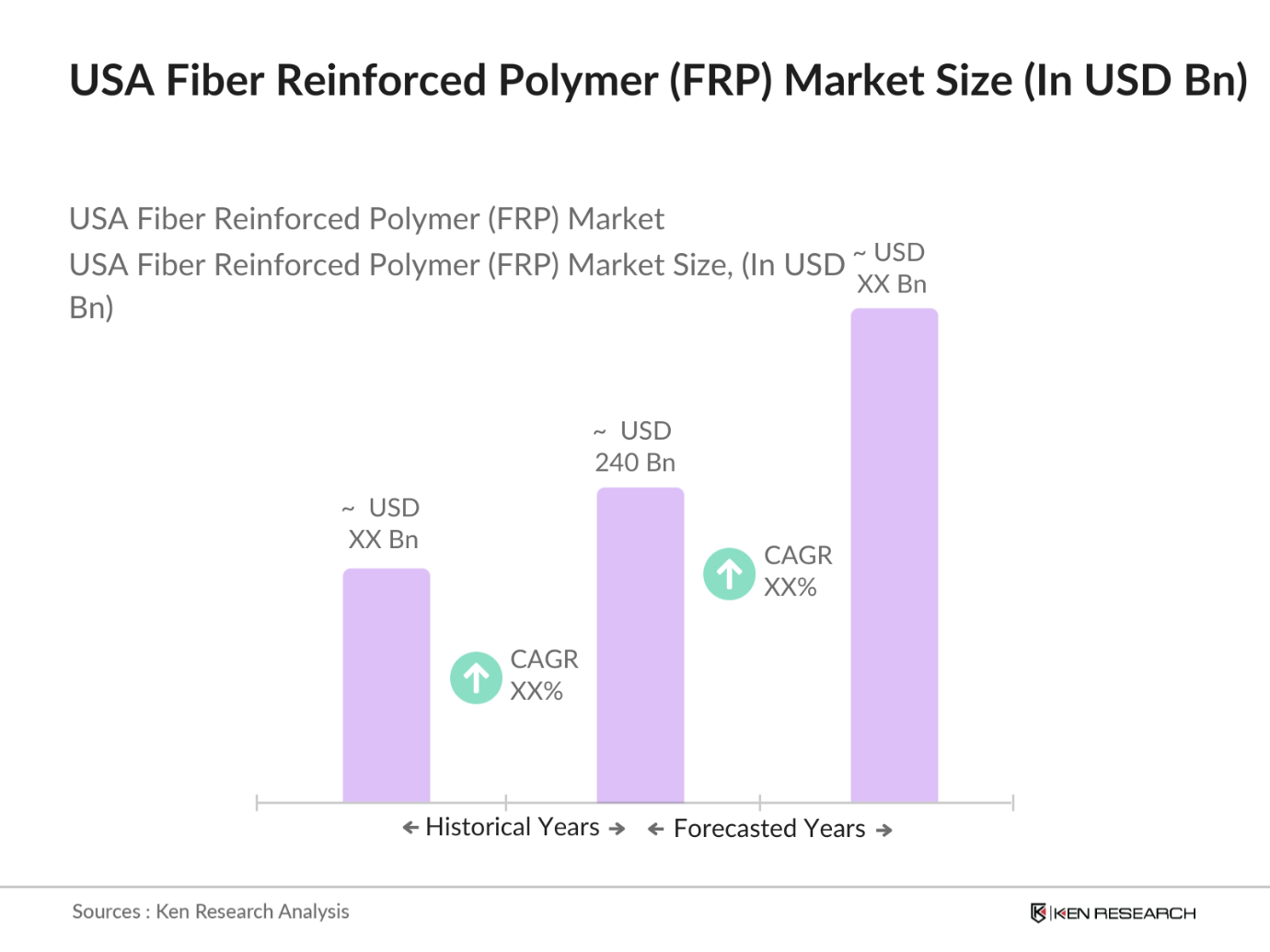

- The USA Fiber Reinforced Polymer (FRP) market is valued at USD 240 billion, based on a five-year historical analysis. It is primarily driven by increased demand for lightweight and high-strength materials across key industries, including automotive, aerospace, and construction. Significant adoption in infrastructure projects and the emphasis on sustainable materials have further accelerated market growth, with substantial support from federal infrastructure initiatives.

- The market exhibits regional dominance in states with extensive industrial and infrastructure development, such as California, Texas, and New York. These states lead due to high investments in infrastructure and stringent sustainability mandates. Additionally, proximity to manufacturing hubs and a robust supply chain ecosystem in these regions have strengthened their standing in the FRP market.

- The Environmental Protection Agency (EPA) mandates strict environmental standards for materials used in construction and automotive sectors. These guidelines require FRP to meet low VOC (Volatile Organic Compound) emissions and high durability criteria, aligning with national sustainability objectives. Compliance with these standards is essential for FRP manufacturers seeking government contracts, particularly for infrastructure projects where material resilience is critical for public safety

USA Fiber Reinforced Polymer (FRP) Market Segmentation

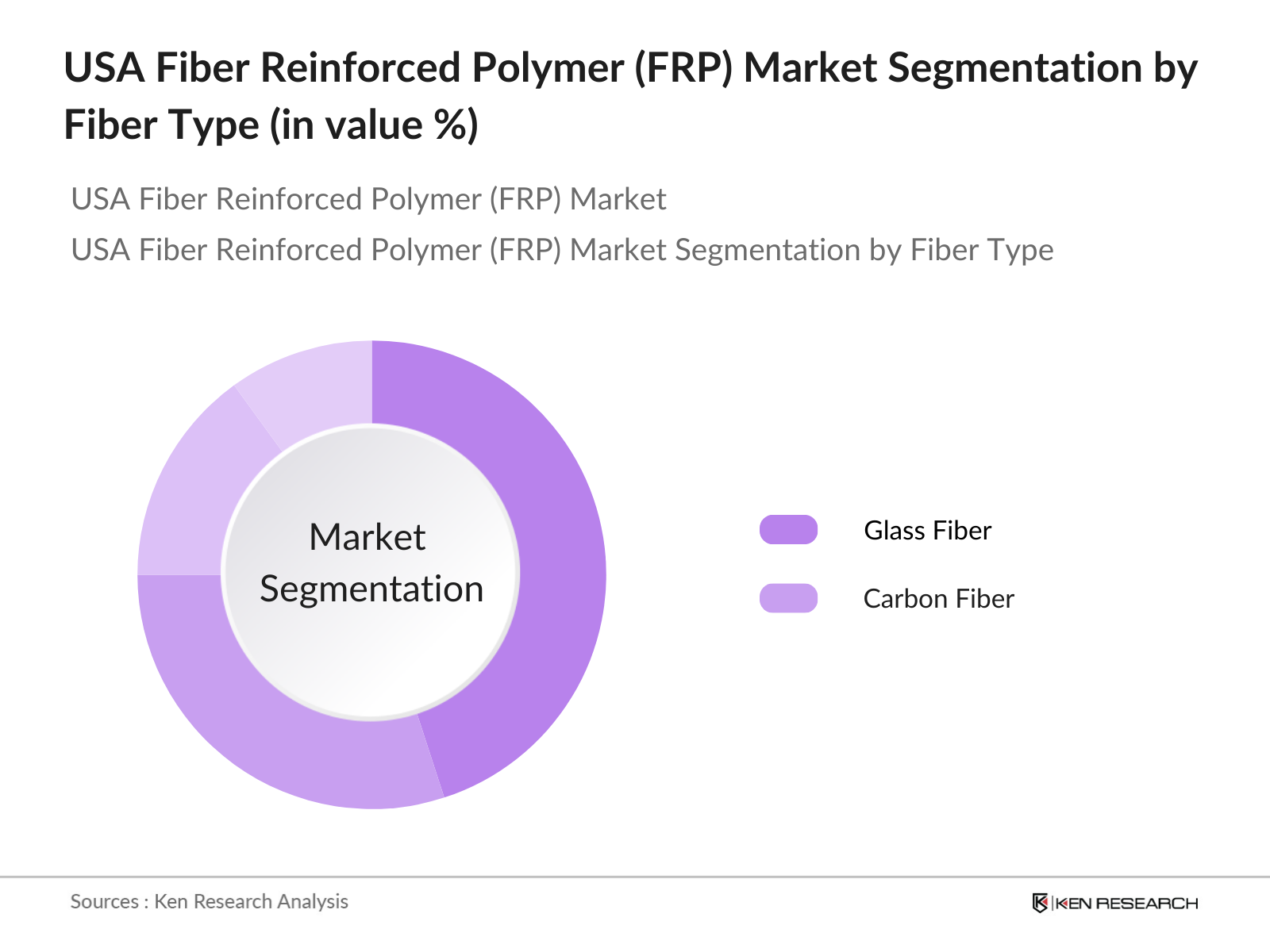

- By Fiber Type: The market is segmented into Glass fiber and Carbon fiber. The segment is dominated by glass fiber, primarily due to its affordability, wide applicability, and high tensile strength. Its use spans across industries including automotive and construction, where durability and cost-effectiveness are key requirements. Manufacturers benefit from extensive applications in infrastructure projects where structural reinforcement is critical.

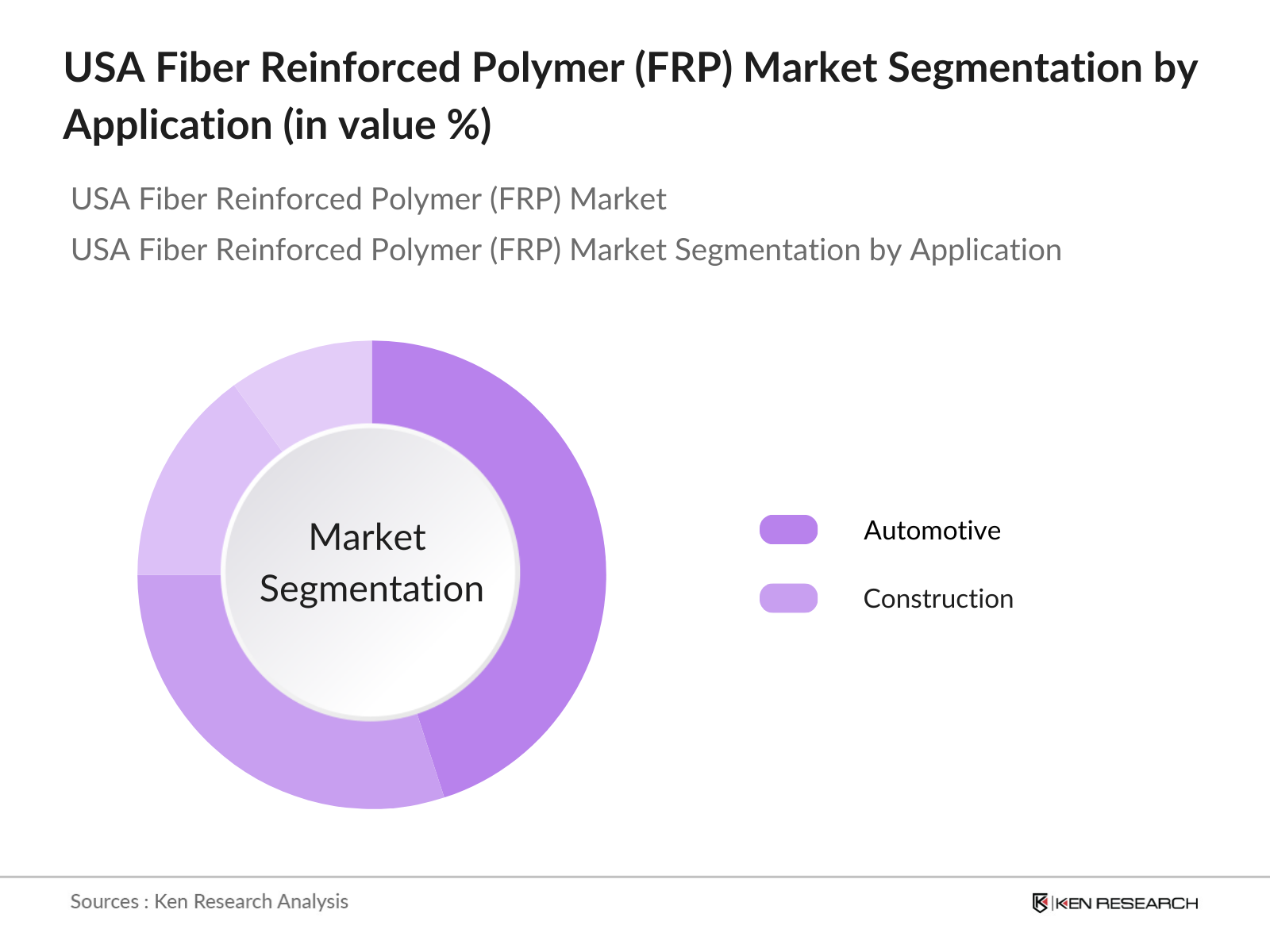

- By Application: The market is segmented into Automotive and construction. Within applications, automotive dominates due to FRPs critical role in vehicle light-weighting for improved fuel efficiency. Leading automotive companies leverage FRP to develop lighter yet stronger vehicle components, supporting compliance with regulatory fuel standards and driving the demand in this segment.

USA Fiber Reinforced Polymer (FRP) Market Competitive Landscape

The USA FRP market is led by both domestic and international players, with competitive positioning based on advanced manufacturing techniques, product range, and application-specific customization. Companies like Owens Corning and Hexcel Corporation lead in product innovation and application diversity, while others focus on specific industries like automotive or aerospace.

USA Fiber Reinforced Polymer (FRP) Market Analysis

Growth Drivers

- Infrastructure Development and Urbanization: The USAs ongoing infrastructure upgrades are boosting demand for fiber-reinforced polymers. With over $110 billion allocated for roads, bridges, and other projects under federal initiatives like the Infrastructure Investment and Jobs Act, the need for durable, lightweight materials such as FRP has risen. FRP materials provide corrosion resistance and high strength, aligning well with the governments push for sustainable and resilient infrastructure. The materials' low maintenance cost appeals to municipalities looking for long-term solutions in harsh environmental conditions, ensuring FRP's relevance in the public works sector.

- Increased Demand in Automotive Lightweighting: In 2024, with the automotive industry contributing roughly $1.2 trillion to the U.S. economy, lightweight materials like FRP are integral to meet stringent fuel efficiency and emissions standards. FRP components reduce vehicle weight by up to 60% compared to traditional materials, directly aiding fuel efficiency in both conventional and electric vehicles (EVs). As manufacturers intensify their focus on EV production, FRP usage has become essential for battery enclosures and other high-stress components. Data from the U.S. Department of Energy supports the material's critical role in automotive sustainability initiatives

- Sustainability Goals in Construction: The construction sector, a significant contributor to emissions, is increasingly adopting FRP to meet environmental standards. According to the U.S. Environmental Protection Agency, construction accounts for approximately 39% of CO emissions nationwide, driving demand for sustainable materials. FRPs recyclable nature and durability make it valuable for structures subjected to extreme weather. As green building standards become more prevalent, the construction industrys shift toward eco-friendly materials like FRP is becoming apparent, especially in areas prone to environmental degradation.

Market Challenges

- High Production Costs of Fiber-Reinforced Polymers: FRPs high production costs remain a significant challenge, as manufacturing FRP components requires advanced technology and precise engineering. According to the U.S. Bureau of Labor Statistics, labor and technology costs have seen an annual increase of about 3%, impacting FRP production budgets. Additionally, the materials required for FRP, such as carbon fibers, are still more expensive than traditional steel and aluminum. The cost factor is a substantial barrier, limiting FRPs broader application across budget-constrained sectors like local infrastructure projects

- Regulatory Compliance and Safety Standards: Meeting regulatory requirements for FRP products in the U.S. requires adherence to complex safety and environmental guidelines. The U.S. Environmental Protection Agency has strict regulations for materials used in public and industrial applications, mandating high fire resistance and structural integrity. Compliance testing and certification processes add time and expense, often delaying FRP projects. Companies also face challenges adapting FRP for high-stress environments, as the materials performance standards can vary based on fiber composition and application

USA Fiber Reinforced Polymer (FRP) Future Outlook

Over the next five years, the USA Fiber Reinforced Polymer (FRP) market is anticipated to expand significantly, driven by increased industrial demand, innovations in composite manufacturing, and regulatory support for sustainable materials. The continued push for lightweight, durable materials across automotive, construction, and aerospace applications will further fuel growth, alongside ongoing advancements in FRP production processes.

Market Opportunities

- Expansion of Renewable Energy Applications: With the U.S. aiming to double its renewable energy output by 2030, FRP is emerging as a vital component in wind turbine and solar panel frameworks. The Department of Energy states that wind energy infrastructure requires durable, lightweight materials, particularly for large turbine blades that endure high-speed rotation. FRPs strength and resistance to environmental wear make it ideal for energy applications, facilitating longer operational life for renewable installations. The material's increasing adoption in this sector presents a significant opportunity for FRP manufacturers.

- Advancements in Composite Technologies: Ongoing research and development in composite technology, supported by the National Science Foundation, is enhancing FRPs properties, making it more versatile across various applications. Innovations in hybrid FRP composites, which combine carbon and glass fibers, are enabling materials with both high strength and reduced costs. These advancements align with industry trends towards multi-functional, lightweight composites, which are increasingly sought after in high-performance sectors like aerospace and defense.

Scope of the Report

|

Segment |

Sub-Segments |

|

By Fiber Type |

- Glass Fiber |

|

- Carbon Fiber |

|

|

- Aramid Fiber |

|

|

By Application |

- Automotive |

|

- Construction |

|

|

- Aerospace |

|

|

- Energy |

|

|

By Resin Type |

- Polyester |

|

- Vinyl Ester |

|

|

- Epoxy |

|

|

By Manufacturing Process |

- Pultrusion |

|

- Filament Winding |

|

|

- Injection Molding |

|

|

- Compression Molding |

|

|

By Region |

- North East |

|

- Midwest |

|

|

- South |

|

|

- West |

Products

Key Target Audience

Investor and Venture Capitalist Firms

Government and Regulatory Bodies (Department of Energy, Environmental Protection Agency)

Automotive and Aerospace Manufacturers

Construction and Infrastructure Firms

Renewable Energy Providers

Material Science Research Organizations

Industry Associations (American Composite Manufacturers Association)

Sustainability Focused Non-profits

Companies

Players Mentioned in the report

Owens Corning

Hexcel Corporation

Teijin Limited

Mitsubishi Chemical

SGL Carbon SE

Strongwell Corporation

Composites One LLC

Toray Industries, Inc.

Zoltek Corporation

Jiangsu Hengshen Co. Ltd

Solvay SA

Plasan Carbon Composites Inc.

Exel Composites

Fiberline Composites

AGY Holding Corp

Table of Contents

1. USA Fiber Reinforced Polymer (FRP) Market Overview

1.1. Definition and Scope

1.2. Market Taxonomy

1.3. Market Composition by Fiber Type

1.4. Key Material Sources

2. USA Fiber Reinforced Polymer (FRP) Market Size (In USD Bn)

2.1. Historical Market Size

2.2. Market Composition by Application Type

2.3. Key Growth Milestones

3. USA Fiber Reinforced Polymer (FRP) Market Dynamics

3.1. Growth Drivers

3.1.1. Infrastructure Development

3.1.2. Rising Use in Automotive and Aerospace Sectors

3.1.3. Sustainability Goals Impact

3.2. Market Challenges

3.2.1. High Production Costs

3.2.2. Regulatory Compliance

3.2.3. Supply Chain Constraints

3.3. Opportunities

3.3.1. Advancements in Composite Technologies

3.3.2. Expansion in Renewable Energy Applications

3.3.3. Increasing Lightweight Material Demand

3.4. Trends

3.4.1. Integration with Additive Manufacturing

3.4.2. Growth in High-Performance FRP Materials

3.4.3. Automation in Manufacturing Processes

3.5. Government Regulation

3.5.1. Environmental Compliance Standards

3.5.2. Safety and Durability Regulations

3.5.3. Tax Incentives for Sustainable Materials

3.6. SWOT Analysis

3.7. Stakeholder Ecosystem

3.8. Porters Five Forces Analysis

3.9. Competitive Landscape Overview

4. USA Fiber Reinforced Polymer (FRP) Market Segmentation

4.1. By Fiber Type (In Value %)

4.1.1. Glass Fiber

4.1.2. Carbon Fiber

4.1.3. Aramid Fiber

4.2. By Application (In Value %)

4.2.1. Automotive

4.2.2. Construction

4.2.3. Aerospace

4.2.4. Energy

4.3. By Resin Type (In Value %)

4.3.1. Polyester

4.3.2. Vinyl Ester

4.3.3. Epoxy

4.4. By Manufacturing Process (In Value %)

4.4.1. Pultrusion

4.4.2. Filament Winding

4.4.3. Injection Molding

4.4.4. Compression Molding

4.5. By Region (In Value %)

4.5.1. North East

4.5.2. Midwest

4.5.3. South

4.5.4. West

5. USA Fiber Reinforced Polymer (FRP) Market Competitive Analysis

5.1. Detailed Profiles of Major Companies

5.1.1. Owens Corning

5.1.2. Teijin Limited

5.1.3. Hexcel Corporation

5.1.4. Toray Industries Inc.

5.1.5. Mitsubishi Chemical Holdings Corporation

5.1.6. SGL Carbon SE

5.1.7. AGY Holding Corp

5.1.8. Strongwell Corporation

5.1.9. Composites One LLC

5.1.10. Zoltek Corporation

5.1.11. Jiangsu Hengshen Co. Ltd

5.1.12. Solvay SA

5.1.13. Plasan Carbon Composites Inc.

5.1.14. Exel Composites

5.1.15. Fiberline Composites

5.2. Cross Comparison Parameters (No. of Employees, Headquarters, Inception Year, Revenue, Product Portfolio Depth, Regional Focus, Patents Filed, R&D Investments)

5.3. Market Share Analysis

5.4. Strategic Initiatives

5.5. Mergers and Acquisitions

5.6. Investment Analysis

5.7. Venture Capital Funding

5.8. Government Incentives

6. USA Fiber Reinforced Polymer (FRP) Market Regulatory Framework

6.1. Environmental Compliance Standards

6.2. Safety and Quality Certifications

6.3. Industrial Codes and Practices

7. USA Fiber Reinforced Polymer (FRP) Future Market Size (In USD Bn)

7.1. Projected Market Size

7.2. Key Factors Influencing Future Growth

8. USA Fiber Reinforced Polymer (FRP) Future Market Segmentation

8.1. By Fiber Type (In Value %)

8.2. By Application (In Value %)

8.3. By Resin Type (In Value %)

8.4. By Manufacturing Process (In Value %)

8.5. By Region (In Value %)

9. USA Fiber Reinforced Polymer (FRP) Market Analysts Recommendations

9.1. TAM/SAM/SOM Analysis

9.2. End-User Demand Analysis

9.3. Distribution Channel Analysis

9.4. White Space Opportunity Analysis

Disclaimer Contact UsResearch Methodology

Step 1: Identification of Key Variables

We begin by constructing an industry map to encompass all major stakeholders within the FRP market. This includes primary data from trusted databases and secondary data to define critical variables affecting market dynamics.

Step 2: Market Analysis and Construction

Historical data for the FRP market is gathered, focusing on application areas and regional demand patterns. This phase also includes an analysis of fiber type distribution and revenue patterns to ensure accuracy.

Step 3: Hypothesis Validation and Expert Consultation

Market hypotheses are tested through expert interviews across multiple sectors, including automotive and construction, to confirm projections and validate segment performance.

Step 4: Research Synthesis and Final Output

We finalize the analysis through direct input from FRP manufacturers and end-users, ensuring that data accurately reflects industry trends and consumer preferences.

Frequently Asked Questions

01. How big is the USA Fiber Reinforced Polymer (FRP) Market?

The USA FRP market is valued at USD 240 billion, primarily driven by demand from construction and automotive industries, alongside federal sustainability initiatives.

02. What challenges are faced by the USA Fiber Reinforced Polymer (FRP) Market?

Key challenges include high production costs, stringent regulatory compliance, and raw material availability, impacting scalability and profitability for manufacturers.

03. Who are the major players in the USA Fiber Reinforced Polymer (FRP) Market?

Leading companies include Owens Corning, Hexcel Corporation, and Teijin Limited, all known for innovation and specialized applications in various industries.

04. What drives the USA Fiber Reinforced Polymer (FRP) Market?

Growth is fueled by an increasing need for lightweight materials in automotive and aerospace, along with robust government support for sustainable construction materials.

05. Which segments dominate the USA Fiber Reinforced Polymer (FRP) Market?

Glass fiber dominates due to cost-effectiveness and versatility, while carbon fiber is preferred in high-performance sectors like aerospace and automotive.

Why Buy From Us?

What makes us stand out is that our consultants follows Robust, Refine and Result (RRR) methodology. i.e. Robust for clear definitions, approaches and sanity checking, Refine for differentiating respondents facts and opinions and Result for presenting data with story

We have set a benchmark in the industry by offering our clients with syndicated and customized market research reports featuring coverage of entire market as well as meticulous research and analyst insights.

While we don't replace traditional research, we flip the method upside down. Our dual approach of Top Bottom & Bottom Top ensures quality deliverable by not just verifying company fundamentals but also looking at the sector and macroeconomic factors.

With one step in the future, our research team constantly tries to show you the bigger picture. We help with some of the tough questions you may encounter along the way: How is the industry positioned? Best marketing channel? KPI's of competitors? By aligning every element, we help maximize success.

Our report gives you instant access to the answers and sources that other companies might choose to hide. We elaborate each steps of research methodology we have used and showcase you the sample size to earn your trust.

If you need any support, we are here! We pride ourselves on universe strength, data quality, and quick, friendly, and professional service.