USA Surface Mount Technology Market Outlook to 2030

Region:North America

Author(s):Yogita Sahu

Product Code:KROD6505

December 2024

90

About the Report

USA Surface Mount Technology Market Overview

- The USA Surface Mount Technology (SMT) market is valued at USD 120 million, driven by increasing demand for smaller, lighter, and more efficient electronic devices. Key factors include advancements in electronics manufacturing processes, growing demand for consumer electronics, and the need for high-performance components in sectors such as automotive and healthcare. The adoption of IoT devices and 5G technology has further fueled this demand, enabling faster and more efficient production.

- North America, particularly the USA, dominates the SMT market due to its advanced electronics manufacturing infrastructure and the presence of leading companies like CyberOptics and Teradyne. The dominance is driven by the region's innovation in high-tech industries, such as telecommunications, defense, and automotive. Moreover, the USAs strategic focus on electric vehicle (EV) manufacturing and adoption of IoT-enabled devices enhances the demand for SMT equipment.

- The U.S. government has allocated $52 billion in 2024 under the CHIPS Act to boost domestic semiconductor manufacturing. This initiative is expected to directly benefit the SMT market by increasing the production capacity for SMT components in the U.S., reducing dependence on foreign suppliers, and promoting local manufacturing. This support will also aid in overcoming supply chain disruptions and fostering innovation in SMT technologies.

USA Surface Mount Technology Market Segmentation

By Component: The market is segmented by component into passive components and active components. Passive Components include resistors, capacitors, and inductors. These components account for a dominant share due to their widespread application in various electronic devices and the growth in consumer electronics. Passive components do not require an external power source, making them essential for efficient circuit designs.

By End-Use Industry: The market is also segmented by end-use industry into consumer electronics, automotive, telecommunications, and healthcare. Consumer Electronics holds the largest share due to high demand for devices like smartphones, tablets, and gaming consoles. The rising need for compact, portable devices fuels the adoption of SMT technology in this segment. Brands are continuously investing in innovations to create devices with smaller form factors, which SMT enables.

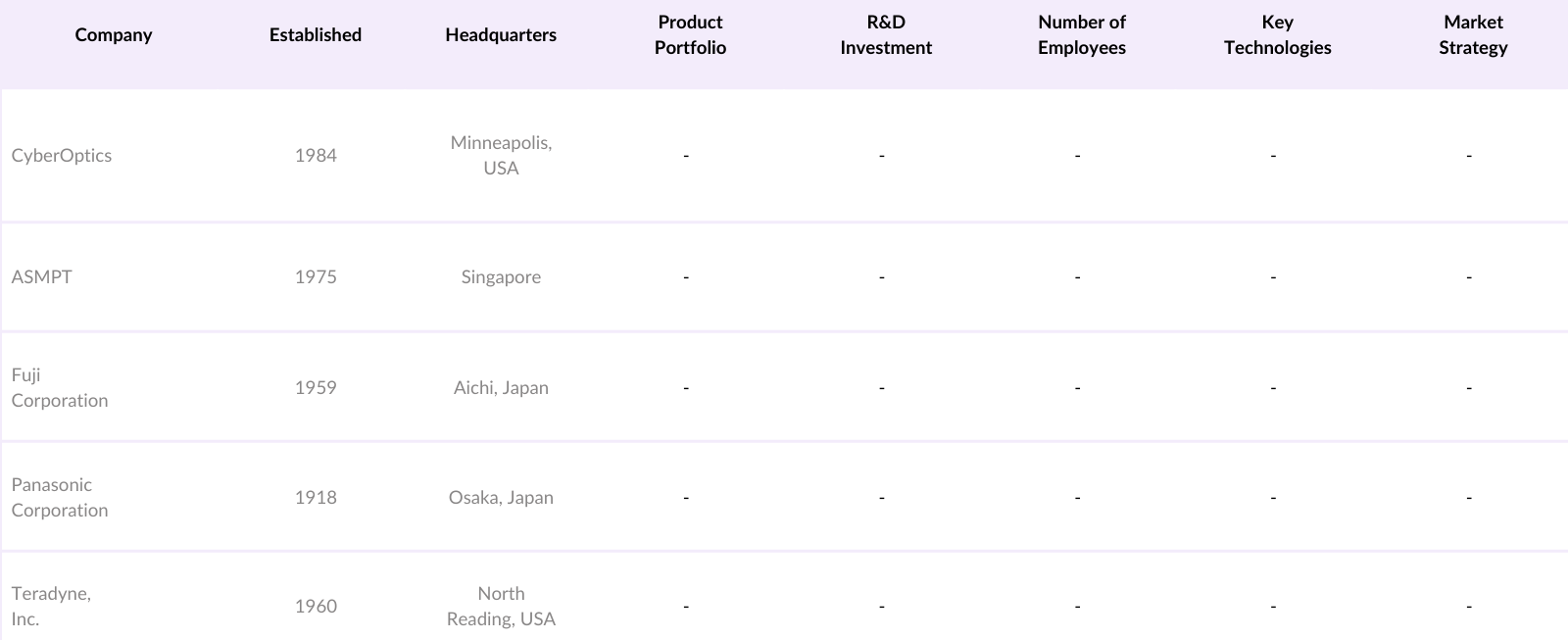

USA Surface Mount Technology Market Competitive Landscape

The market is highly competitive, with major global and local players driving innovations and strategic investments. The market is dominated by companies offering diverse products across multiple segments, focusing on expanding their presence through mergers and acquisitions.

USA Surface Mount Technology Market Analysis

Market Growth Drivers

- Increasing Demand for Miniaturization in Electronics: The growing demand for smaller, more efficient consumer electronics is fueling the need for Surface Mount Technology (SMT). In 2024, over 8 billion devices, including smartphones, tablets, and wearables, are expected to utilize SMT for their compact size and higher component density.

- Surge in Automotive Electronics Production: The automotive industry is increasingly adopting advanced electronic systems, such as safety controls and infotainment, which require surface mount components. In 2024, the global production of electric and autonomous vehicles is projected to cross 20 million units, each equipped with thousands of SMT-based components, like sensors, actuators, and control modules.

- Adoption of Industry 4.0 in Manufacturing: The rise of Industry 4.0 is promoting automation and smart manufacturing, driving the demand for highly efficient SMT machines. By 2024, nearly 12,000 smart manufacturing plants globally are expected to deploy automated SMT assembly lines, increasing production capacity by up to 25%. This trend is supported by the ongoing investments in advanced manufacturing infrastructure, with governments and private entities investing heavily in Industry 4.0 initiatives, further bolstering the SMT market.

Market Challenges

- Supply Chain Disruptions: The SMT market is vulnerable to global supply chain disruptions, particularly in sourcing critical components like semiconductors and circuit boards. In 2024, the global semiconductor shortage is projected to result in a shortfall of over 50 million SMT components, leading to production delays in several industries, including automotive and consumer electronics.

- Environmental Regulations: Stricter environmental regulations on the use of hazardous materials in electronics manufacturing are posing challenges for the SMT industry. By 2024, global regulatory bodies are expected to tighten restrictions on materials like lead and mercury, increasing compliance costs for manufacturers.

USA Surface Mount Technology Market Future Outlook

The USA Surface Mount Technology industry is projected to continue its growth trajectory over the next five years, driven by the increasing demand for electric vehicles, advancements in telecommunication infrastructure, and the proliferation of IoT devices.

Future Market Opportunities

- Adoption of Flexible SMT Components for Wearables: The wearables market is expected to be a key growth driver for SMT over the next five years. By 2029, the production of flexible SMT components for wearable devices is anticipated to exceed 1 billion units annually. These components will be critical in developing smaller, more flexible wearables, such as fitness trackers and smartwatches, meeting consumer demand for advanced functionality in compact designs.

- AI-Driven Manufacturing in SMT Production: AI-driven manufacturing is expected to play a transformative role in SMT production by 2029. Companies that adopt AI technologies in their assembly lines are projected to increase production efficiency by up to 35% over the next five years. AI will enhance the precision, speed, and scalability of SMT production, driving down costs and improving product quality in industries like consumer electronics, automotive, and healthcare.

Scope of the Report

|

By Component |

Passive (Resistors, Capacitors) |

|

Active (Transistors, ICs) |

|

|

By Equipment Type |

Placement Inspection Soldering Rework |

|

By End-Use Industry |

Consumer Electronics Automotive Telecommunication Aerospace & Defense Healthcare |

|

By Region |

North East West South |

Products

Key Target Audience Organizations and Entities Who Can Benefit by Subscribing This Report:

Electronic Manufacturers

Automotive OEMs

Healthcare Device Manufacturers

Telecommunication Equipment Providers

Consumer Electronics Producers

Investor and Venture Capitalist Firms

Government and Regulatory Bodies (e.g., Federal Communications Commission, Environmental Protection Agency)

Electric Vehicle Manufacturers

Companies

Players Mentioned in the Report:

CyberOptics Corporation

ASMPT

Fuji Corporation

Panasonic Corporation

Teradyne, Inc.

Yamaha Motor Co., Ltd.

Mycronic AB

Nordson Corporation

Hanwha Precision Machinery

Juki Corporation

Table of Contents

USA Surface Mount Technology Market Overview

1.1 Definition and Scope

1.2 Market Taxonomy

1.3 Market Growth Rate

1.4 Market Segmentation Overview

USA Surface Mount Technology Market Size (In USD Mn)

2.1 Historical Market Size

2.2 Key Market Developments and Milestones

2.3 Growth Analysis

USA Surface Mount Technology Market Analysis

3.1 Growth Drivers

3.1.1 Rising Demand for Miniaturization (Component Size, Performance Efficiency)

3.1.2 Increasing Consumer Electronics Adoption (Wearables, Smartphones)

3.1.3 Demand for High-Density PCB Assemblies (Telecommunication, Automotive)

3.1.4 Integration with IoT Devices

3.2 Market Challenges

3.2.1 High Initial Equipment Cost

3.2.2 Technological Obsolescence

3.2.3 Complexity in Manufacturing Processes

3.3 Market Opportunities

3.3.1 Expansion of EV and Battery Systems (Automotive)

3.3.2 Growth in IoT and Wearable Tech Devices

3.3.3 Innovation in Advanced PCB Assembly

3.4 Trends

3.4.1 Integration of AI in Manufacturing Systems

3.4.2 Adoption of Flexible PCBs

3.4.3 Rise in Use of Compact Consumer Devices

USA Surface Mount Technology Market Segmentation

4.1 By Component (In Value %)

4.1.1 Passive Components (Resistors, Capacitors)

4.1.2 Active Components (Transistors, Integrated Circuits)

4.2 By Equipment Type (In Value %)

4.2.1 Placement Machines

4.2.2 Inspection Equipment

4.2.3 Soldering Equipment

4.2.4 Rework/Repair Equipment

4.3 By End-Use Industry (In Value %)

4.3.1 Consumer Electronics

4.3.2 Automotive

4.3.3 Telecommunications

4.3.4 Aerospace & Defense

4.3.5 Healthcare Devices

4.4 By Region (In Value %)

4.4.1 North

4.4.2 East

4.4.3 West

4.4.4 South

USA Surface Mount Technology Competitive Analysis

5.1 Detailed Profiles of Major Companies

5.1.1 Fuji Corporation

5.1.2 Yamaha Motor Co. Ltd.

5.1.3 ASMPT

5.1.4 Panasonic Corporation

5.1.5 Nordson Corporation

5.1.6 Hanwha Precision Machinery

5.1.7 Juki Corporation

5.1.8 Viscom AG

5.1.9 CyberOptics Corporation

5.1.10 Essemtec AG

5.1.11 Mycronic AB

5.1.12 Europlacer Ltd.

5.1.13 Saki Corporation

5.1.14 Aurotek Corporation

5.1.15 Universal Instruments Corporation

5.2 Cross Comparison Parameters (Revenue, Market Share, Product Portfolio, Technological Innovation)

5.3 Strategic Initiatives (Partnerships, Acquisitions, Investments)

5.4 Market Share Analysis

USA Surface Mount Technology Market Regulatory Framework

6.1 Industry Standards for SMT

6.2 Compliance and Certification Requirements

USA Surface Mount Technology Future Market Size (In USD Mn)

7.1 Future Market Size Projections

7.2 Key Factors Driving Future Market Growth

USA Surface Mount Technology Future Market Segmentation

8.1 By Component (In Value %)

8.2 By Equipment Type (In Value %)

8.3 By End-Use Industry (In Value %)

8.4 By Region (In Value %)

USA Surface Mount Technology Market Analysts' Recommendations

9.1 TAM/SAM/SOM Analysis

9.2 Marketing Initiatives

9.3 White Space Opportunity Analysis

Disclaimer Contact UsResearch Methodology

Step 1: Identification of Key Variables

The research begins with mapping the entire ecosystem of the USA Surface Mount Technology Market. Extensive desk research is conducted to identify key variables that affect market dynamics, such as component demand, industry growth, and technology trends. Both proprietary and secondary sources are used.

Step 2: Market Analysis and Construction

Historical data related to SMT equipment sales, usage in industries like automotive and consumer electronics, and demand for passive/active components are analyzed. This phase helps in understanding the revenue generation and market penetration.

Step 3: Hypothesis Validation and Expert Consultation

Market hypotheses are developed and validated through interviews with industry experts from key SMT companies. This includes senior executives and supply chain managers, who provide insights into technological advancements and customer preferences.

Step 4: Research Synthesis and Final Output

The final phase involves engaging with SMT equipment manufacturers and industry practitioners. This stage is crucial for verifying data derived from the bottom-up approach, ensuring the report provides accurate and comprehensive market insights.

Frequently Asked Questions

01. How big is the USA Surface Mount Technology Market?

The USA Surface Mount Technology market is valued at USD 120 million, driven by demand for smaller, more efficient electronic devices and technological advancements in the field.

02. What are the challenges in the USA Surface Mount Technology Market?

Challenges in the USA Surface Mount Technology market include high initial costs for SMT equipment and rapid technological advancements that require continuous innovation to stay competitive.

03. Who are the major players in the USA Surface Mount Technology Market?

Key players in the USA Surface Mount Technology market include CyberOptics Corporation, Panasonic Corporation, ASMPT, Fuji Corporation, and Teradyne, Inc. These companies dominate due to their strong technological portfolios and R&D investments.

04. What drives the growth of the USA Surface Mount Technology Market?

Growth in the USA Surface Mount Technology market is driven by increasing demand for IoT devices, automotive innovations like electric vehicles, and the miniaturization of electronic components in consumer electronics.

05. How is the USA Surface Mount Technology Market segmented?

The USA Surface Mount Technology market is segmented by component into passive and active components, and by end-use industries such as consumer electronics, automotive, and telecommunications.

Why Buy From Us?

What makes us stand out is that our consultants follows Robust, Refine and Result (RRR) methodology. i.e. Robust for clear definitions, approaches and sanity checking, Refine for differentiating respondents facts and opinions and Result for presenting data with story

We have set a benchmark in the industry by offering our clients with syndicated and customized market research reports featuring coverage of entire market as well as meticulous research and analyst insights.

While we don't replace traditional research, we flip the method upside down. Our dual approach of Top Bottom & Bottom Top ensures quality deliverable by not just verifying company fundamentals but also looking at the sector and macroeconomic factors.

With one step in the future, our research team constantly tries to show you the bigger picture. We help with some of the tough questions you may encounter along the way: How is the industry positioned? Best marketing channel? KPI's of competitors? By aligning every element, we help maximize success.

Our report gives you instant access to the answers and sources that other companies might choose to hide. We elaborate each steps of research methodology we have used and showcase you the sample size to earn your trust.

If you need any support, we are here! We pride ourselves on universe strength, data quality, and quick, friendly, and professional service.