Region:Middle East

Author(s):Geetanshi

Product Code:KRAD4860

Pages:82

Published On:December 2025

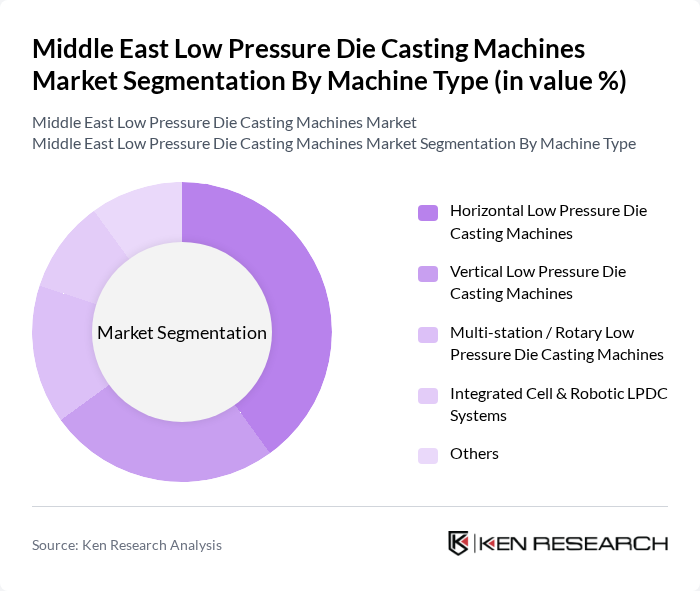

By Machine Type:The market is segmented into various machine types, including Horizontal Low Pressure Die Casting Machines, Vertical Low Pressure Die Casting Machines, Multi-station / Rotary Low Pressure Die Casting Machines, Integrated Cell & Robotic LPDC Systems, and Others. Horizontal Low Pressure Die Casting Machines are widely used for high-volume production of complex aluminum components due to their efficiency, repeatability, and suitability for automated cells, particularly in automotive powertrain, wheels, and structural parts, while the growing adoption of integrated and robotic LPDC systems is linked to Industry 4.0 initiatives and increasing automation in regional foundries.

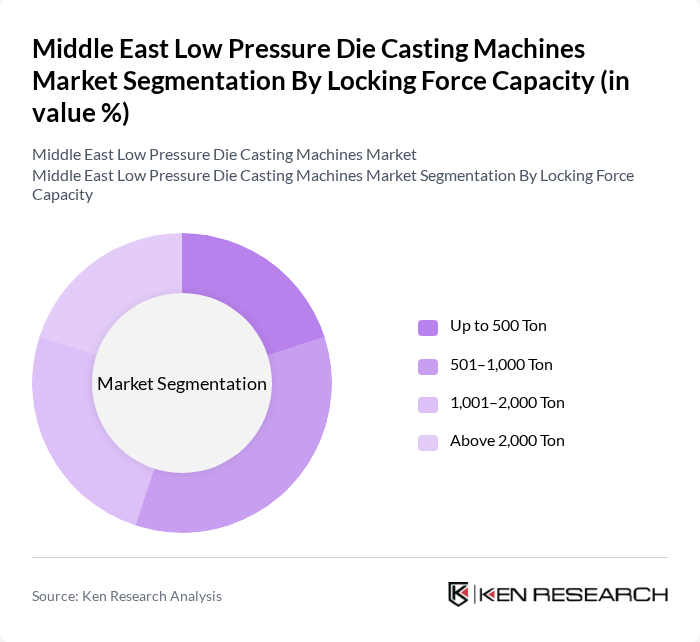

By Locking Force Capacity:The market is categorized based on locking force capacity into segments such as Up to 500 Ton, 501–1,000 Ton, 1,001–2,000 Ton, and Above 2,000 Ton. The segment of 501–1,000 Ton is leading the market due to its suitability for a wide range of medium-to-large aluminum castings used in automotive, industrial machinery, and energy applications, where balanced clamping force, cycle time, and flexibility are required, while higher tonnage machines above 2,000 Ton are increasingly demanded for large structural and chassis components as vehicle lightweighting and complex casting designs continue to advance.

The Middle East Low Pressure Die Casting Machines Market is characterized by a dynamic mix of regional and international players. Leading participants such as Bühler AG, Italpresse Gauss S.r.l., LPM Group S.p.A., Idra Group S.r.l., UBE Industries, Ltd., SINTOKOGIO, LTD. (Sinto Group), CPC Machines, Hashida Giken Inc., Colosio Srl, Zhejiang Wanfeng Technology Development Co., Ltd., Yizumi Precision Machinery Co., Ltd., LK Machinery International Limited (LK Group), Fill Gesellschaft m.b.H., Kurtz Ersa Group, Tünkers Maschinenbau GmbH contribute to innovation, geographic expansion, automation, and service delivery in this space, supported by broader regional adoption of low pressure die casting equipment in automotive, aerospace, energy, and industrial segments.

The future of the Middle East low pressure die casting machines market appears promising, driven by technological advancements and increasing demand for lightweight components. As the automotive and aerospace sectors continue to expand, manufacturers are likely to invest in innovative die casting technologies. Additionally, the integration of Industry 4.0 principles will enhance operational efficiency. However, addressing challenges such as high investment costs and labor shortages will be essential for realizing the full potential of this market in the coming years.

| Segment | Sub-Segments |

|---|---|

| By Machine Type | Horizontal Low Pressure Die Casting Machines Vertical Low Pressure Die Casting Machines Multi-station / Rotary Low Pressure Die Casting Machines Integrated Cell & Robotic LPDC Systems Others |

| By Locking Force Capacity | Up to 500 Ton –1,000 Ton ,001–2,000 Ton Above 2,000 Ton |

| By End-User Industry | Automotive & Commercial Vehicles Aerospace & Defense Oil & Gas and Energy Industrial Machinery & Equipment Construction & Heavy Equipment Others |

| By Casting Application | Wheels and Chassis Components Engine & Powertrain Components Structural & Body-in-White Parts Industrial Housings & Pump Bodies Others |

| By Casting Material | Aluminum Alloys Magnesium Alloys Other Non-ferrous Alloys |

| By Automation Level | Fully Automated LPDC Cells Semi-automated LPDC Machines Manual / Operator-assisted LPDC Machines |

| By Sales Channel | Direct Sales (OEM to Foundry) Distributors / Agents System Integrators & EPC Companies |

| By Country | Saudi Arabia United Arab Emirates Qatar Kuwait Oman Rest of Middle East |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Automotive Components Manufacturing | 120 | Production Managers, Quality Control Engineers |

| Aerospace Parts Production | 90 | Technical Directors, Aerospace Engineers |

| Consumer Electronics Manufacturing | 80 | Product Development Managers, Supply Chain Analysts |

| Industrial Equipment Manufacturing | 70 | Operations Managers, Procurement Specialists |

| Medical Device Manufacturing | 60 | Regulatory Affairs Managers, R&D Directors |

The Middle East Low Pressure Die Casting Machines Market is valued at approximately USD 1.1 billion, driven by the increasing demand for lightweight components in industries such as automotive and aerospace, along with advancements in manufacturing technologies.