Region:Middle East

Author(s):Shubham

Product Code:KRAA8504

Pages:99

Published On:November 2025

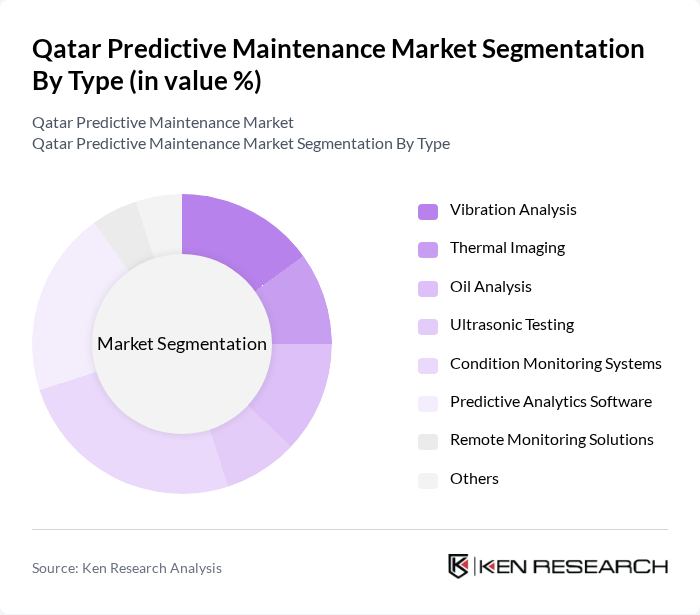

By Type:The predictive maintenance market can be segmented into various types, including Vibration Analysis, Thermal Imaging, Oil Analysis, Ultrasonic Testing, Condition Monitoring Systems, Predictive Analytics Software, Remote Monitoring Solutions, and Others. Each of these sub-segments plays a crucial role in enhancing maintenance strategies across different industries. Among these, Condition Monitoring Systems and Predictive Analytics Software are particularly dominant due to their ability to provide real-time insights and predictive capabilities, which are essential for minimizing downtime and optimizing maintenance schedules .

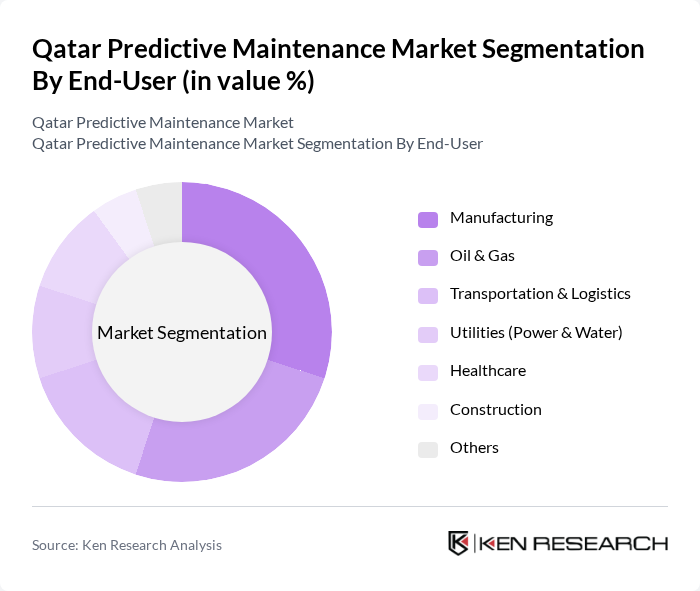

By End-User:The end-user segmentation includes Manufacturing, Oil & Gas, Transportation & Logistics, Utilities (Power & Water), Healthcare, Construction, and Others. The Manufacturing and Oil & Gas sectors are the most significant contributors to the predictive maintenance market, driven by their need for operational efficiency and cost reduction. These industries are increasingly adopting predictive maintenance solutions to enhance equipment reliability and minimize unplanned downtime, which is critical for maintaining productivity and profitability. The adoption of Industry 4.0 practices and digital transformation initiatives further accelerates uptake in these sectors .

The Qatar Predictive Maintenance Market is characterized by a dynamic mix of regional and international players. Leading participants such as Siemens AG, General Electric (GE Digital), Honeywell International Inc., IBM Corporation, Schneider Electric, Rockwell Automation, PTC Inc., SAP SE, Emerson Electric Co., SKF Group, Fluke Corporation, National Instruments, Yokogawa Electric Corporation, ABB Ltd., Altair Engineering, Aspen Technology, Inc., Senseye (a Siemens company), Predictive Maintenance Technologies WLL (Qatar), Ooredoo Q.P.S.C. (IoT & Industrial Solutions), Microsoft Corporation contribute to innovation, geographic expansion, and service delivery in this space.

The future of the predictive maintenance market in Qatar appears promising, driven by technological advancements and increasing industrial automation. As industries continue to embrace digital transformation, the integration of AI and machine learning will enhance predictive capabilities, leading to improved operational efficiency. Furthermore, the government's commitment to smart city initiatives will likely accelerate the adoption of predictive maintenance solutions, fostering a more resilient and sustainable industrial ecosystem in the region.

| Segment | Sub-Segments |

|---|---|

| By Type | Vibration Analysis Thermal Imaging Oil Analysis Ultrasonic Testing Condition Monitoring Systems Predictive Analytics Software Remote Monitoring Solutions Others |

| By End-User | Manufacturing Oil & Gas Transportation & Logistics Utilities (Power & Water) Healthcare Construction Others |

| By Industry | Aerospace Automotive Construction Mining Petrochemicals Others |

| By Technology | IoT Solutions AI and Machine Learning Cloud Computing Edge Computing Digital Twin Technology Others |

| By Application | Equipment Maintenance Asset Management Performance Optimization Safety Management Energy Management Others |

| By Investment Source | Private Investments Government Funding Public-Private Partnerships Venture Capital Others |

| By Policy Support | Subsidies for Technology Adoption Tax Incentives Grants for Research and Development Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Oil & Gas Sector Maintenance | 100 | Maintenance Managers, Operations Directors |

| Manufacturing Predictive Maintenance | 60 | Plant Managers, Engineering Heads |

| Transportation Fleet Management | 50 | Fleet Managers, Logistics Coordinators |

| Utilities Asset Management | 40 | Asset Managers, Reliability Engineers |

| Technology Providers in Predictive Maintenance | 70 | Product Managers, Sales Directors |

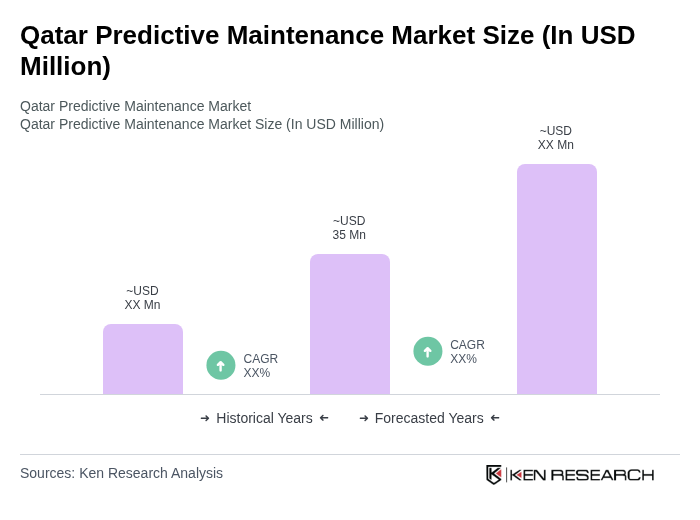

The Qatar Predictive Maintenance Market is valued at approximately USD 35 million, reflecting a significant growth trend driven by the adoption of IoT technologies and predictive analytics across various industries.