Region:Global

Author(s):Shubham

Product Code:KRAD5351

Pages:95

Published On:December 2025

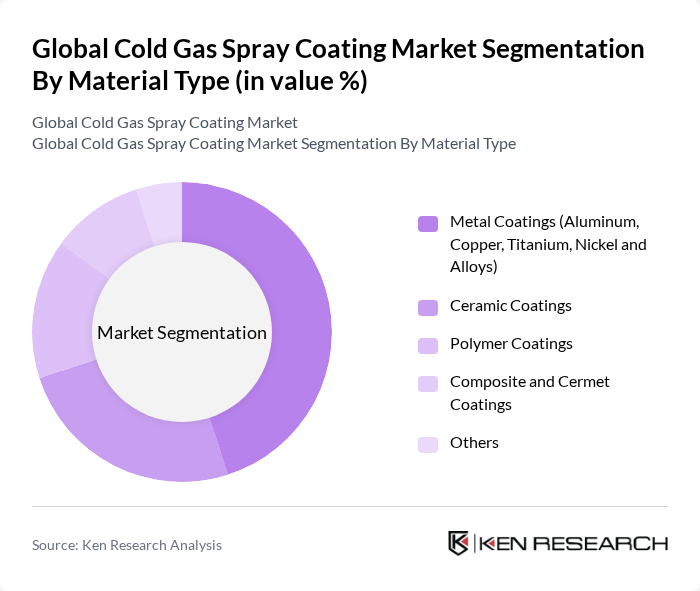

By Material Type:The material type segmentation includes various categories such as metal coatings, ceramic coatings, polymer coatings, composite and cermet coatings, and others. Cold spray is particularly well suited for ductile metals and alloys such as aluminum, copper, titanium, steel, and nickel-based alloys, which can be deposited in thick, dense layers without melting and with high bond strength. Among these, metal coatings, particularly aluminum and titanium, dominate many high-value applications due to their excellent mechanical properties, corrosion resistance, and widespread use in aerospace and automotive components, as well as in energy and electronics for conductive and structural coatings. The demand for lightweight and durable materials, together with the need to repair and extend the life of aluminum and magnesium structures, is driving the preference for these coatings, making them a key focus for manufacturers and system integrators.

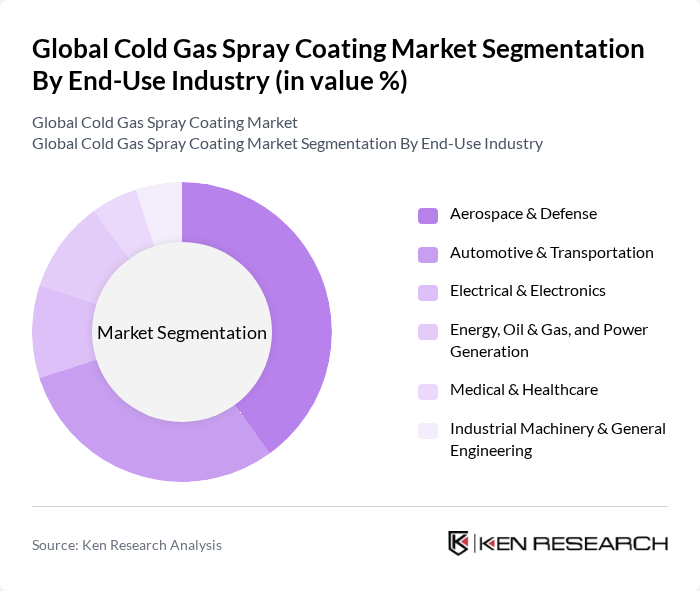

By End-Use Industry:The end-use industry segmentation encompasses aerospace & defense, automotive & transportation, electrical & electronics, energy, oil & gas, medical & healthcare, industrial machinery & general engineering, and others. Cold spray is now widely implemented for surface repair, surface enhancement, functional coatings, and additive manufacturing across aerospace, weapon systems, energy and power, electronics, and medical equipment. The aerospace & defense sector is the leading segment, driven by the need for high-performance coatings that can withstand extreme conditions and enable structural repair of high-value components such as landing gear, structural elements, and engine parts while avoiding thermal distortion. The increasing focus on lightweight materials and fuel efficiency in aircraft and defense platforms, together with maintenance, repair, and overhaul (MRO) strategies using cold spray for life extension of aluminum and magnesium components, further enhances the demand for cold gas spray coatings in this industry.

The Global Cold Gas Spray Coating Market is characterized by a dynamic mix of regional and international players. Leading participants such as Oerlikon Metco AG, Praxair Surface Technologies (Linde plc), Impact Innovations GmbH, VRC Metal Systems LLC, CenterLine (Windsor) Limited, Plasma Giken Co., Ltd., Bodycote plc, Curtiss-Wright Surface Technologies, Flame Spray Technologies BV, ASB Industries Inc., EffusionTech Systems, TST Coatings, Inc., Dycomet Europe BV, Kennametal Inc., 3M Company contribute to innovation, geographic expansion, and service delivery in this space.

The future of the cold gas spray coating market appears promising, driven by technological advancements and increasing demand for sustainable manufacturing practices. As industries prioritize lightweight materials and eco-friendly solutions, the adoption of cold gas spray technology is expected to rise. Furthermore, the integration of automation and Industry 4.0 technologies will enhance efficiency and precision in coating applications, paving the way for innovative uses and broader market acceptance in the coming years.

| Segment | Sub-Segments |

|---|---|

| By Material Type | Metal Coatings (Aluminum, Copper, Titanium, Nickel and Alloys) Ceramic Coatings Polymer Coatings Composite and Cermet Coatings Others |

| By End-Use Industry | Aerospace & Defense Automotive & Transportation Electrical & Electronics Energy, Oil & Gas, and Power Generation Medical & Healthcare Industrial Machinery & General Engineering Others |

| By Application | Surface Repair & Dimensional Restoration Wear & Abrasion Resistance Thermal Barrier & Heat Management Coatings Corrosion & Oxidation Protection Electrical Conductive & Functional Coatings Others |

| By Feedstock Material Form | Metal Powders Ceramic Powders Polymer Powders Composite and Blended Powders Others |

| By Technology | High-Pressure Cold Gas Spray Systems Low-Pressure Cold Gas Spray Systems Portable / Mobile Cold Gas Spray Units Automated & Robotic Cold Gas Spray Cells Others |

| By Region | North America Europe Asia-Pacific Latin America Middle East & Africa |

| By Industry Standards & Certifications | ISO Standards (e.g., ISO 14919, ISO 2063) ASTM Standards (e.g., ASTM C633, ASTM C1624) SAE & AMS Aerospace Material Standards NADCAP and Other Sector-Specific Qualifications Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Aerospace Coating Applications | 120 | Manufacturing Engineers, Quality Assurance Managers |

| Automotive Component Coatings | 100 | Production Managers, Coating Technologists |

| Energy Sector Coating Solutions | 90 | Project Managers, Maintenance Engineers |

| Medical Device Coatings | 60 | Regulatory Affairs Specialists, Product Development Engineers |

| Industrial Equipment Coatings | 80 | Operations Managers, Supply Chain Coordinators |

The Global Cold Gas Spray Coating Market is valued at approximately USD 1.3 billion, reflecting a robust growth trajectory driven by the increasing demand for advanced coating technologies across various industries, including aerospace, automotive, and electronics.