Region:Global

Author(s):Dev

Product Code:KRAA2983

Pages:100

Published On:August 2025

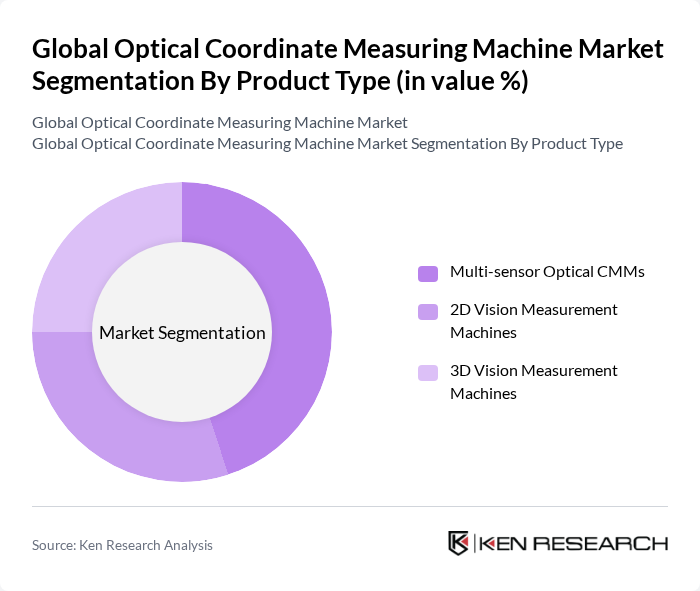

By Product Type:The product type segmentation includes Multi-sensor Optical CMMs, 2D Vision Measurement Machines, and 3D Vision Measurement Machines. Among these, Multi-sensor Optical CMMs are leading the market due to their versatility and ability to perform complex measurements across various materials and geometries. The demand for these machines is driven by their capability to integrate multiple measurement technologies, which enhances accuracy and efficiency in quality control processes. As industries increasingly focus on precision and automation, Multi-sensor Optical CMMs are becoming the preferred choice for manufacturers .

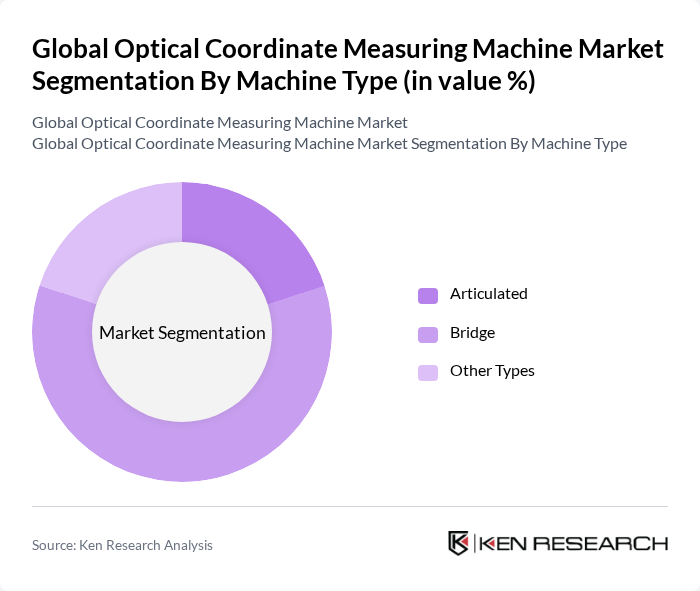

By Machine Type:This segmentation includes Articulated, Bridge, and Other Types. The Bridge type machines dominate the market due to their robustness and high precision, making them ideal for large-scale manufacturing environments. Their ability to handle heavy workpieces and provide accurate measurements has made them a staple in industries such as aerospace and automotive. As manufacturers seek to improve efficiency and reduce errors in production, the demand for Bridge type machines continues to grow .

The Global Optical Coordinate Measuring Machine market is characterized by a dynamic mix of regional and international players. Leading participants such as ZEISS Group, Hexagon AB, Mitutoyo Corporation, Nikon Metrology NV, Renishaw plc, FARO Technologies, Inc., Creaform Inc., WENZEL Group GmbH & Co. KG, AICON 3D Systems GmbH, GOM GmbH, Keyence Corporation, Werth Messtechnik GmbH, Quality Vision International, Inc., TESA Technology (Hexagon Metrology), Perceptron, Inc. contribute to innovation, geographic expansion, and service delivery in this space.

The future of the optical coordinate measuring machine market appears promising, driven by technological advancements and increasing demand for precision in manufacturing. As industries embrace automation and Industry 4.0, the integration of optical CMMs with smart technologies will enhance measurement capabilities. Furthermore, the growing emphasis on sustainability will push manufacturers to adopt more efficient measurement solutions, ensuring compliance with environmental regulations while maintaining high-quality standards in production processes.

| Segment | Sub-Segments |

|---|---|

| By Product Type | Multi-sensor Optical CMMs D Vision Measurement Machines D Vision Measurement Machines |

| By Machine Type | Articulated Bridge Other Types |

| By End-User Industry | Aerospace & Defense Automotive Heavy Machinery and Metal Fabrication Electronics Medical Devices Other End-user Industries |

| By Application | Quality Control Product Development Research and Development Calibration Others |

| By Distribution Channel | Direct Sales Distributors Online Sales Others |

| By Region | North America Europe Asia Pacific Latin America Middle East & Africa |

| By Price Range | Low-End Mid-Range High-End |

| By Technology | Optical Measurement Technology Laser Measurement Technology Hybrid Measurement Technology Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Automotive Manufacturing | 100 | Quality Control Managers, Production Engineers |

| Aerospace Component Production | 70 | Manufacturing Engineers, Compliance Officers |

| Electronics Assembly | 80 | Process Engineers, Quality Assurance Specialists |

| Medical Device Manufacturing | 60 | Regulatory Affairs Managers, R&D Engineers |

| General Manufacturing | 90 | Operations Managers, Supply Chain Coordinators |

The Global Optical Coordinate Measuring Machine market is valued at approximately USD 3.7 billion, driven by the increasing demand for precision measurement in industries such as automotive, aerospace, and electronics, where accuracy is essential for quality control and product reliability.