Region:Global

Author(s):Dev

Product Code:KRAA2624

Pages:94

Published On:August 2025

Market.png)

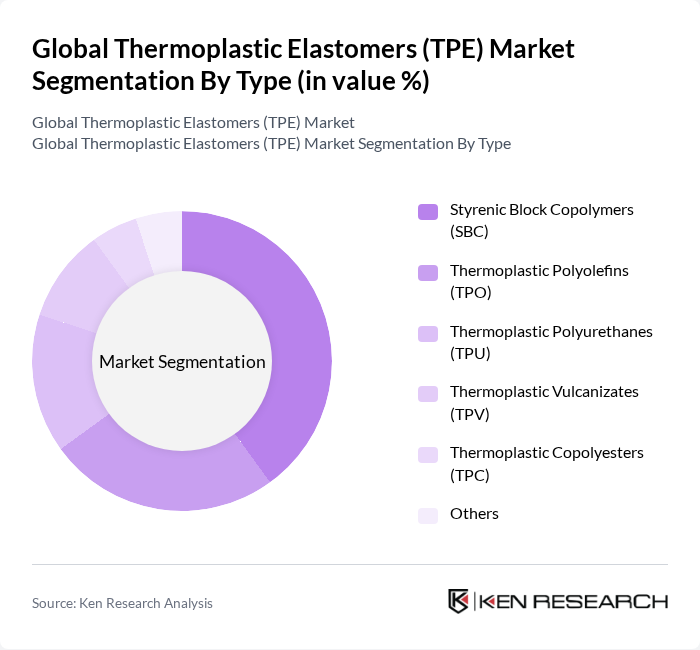

By Type:The TPE market is segmented into various types, including Styrenic Block Copolymers (SBC), Thermoplastic Polyolefins (TPO), Thermoplastic Polyurethanes (TPU), Thermoplastic Vulcanizates (TPV), Thermoplastic Copolyesters (TPC), and others. Among these, Styrenic Block Copolymers (SBC) hold the largest share due to their excellent elasticity, transparency, and resistance to UV light, making them ideal for applications in consumer goods and automotive parts. The versatility and performance characteristics of SBCs have led to their widespread adoption, particularly in the automotive and consumer goods sectors .

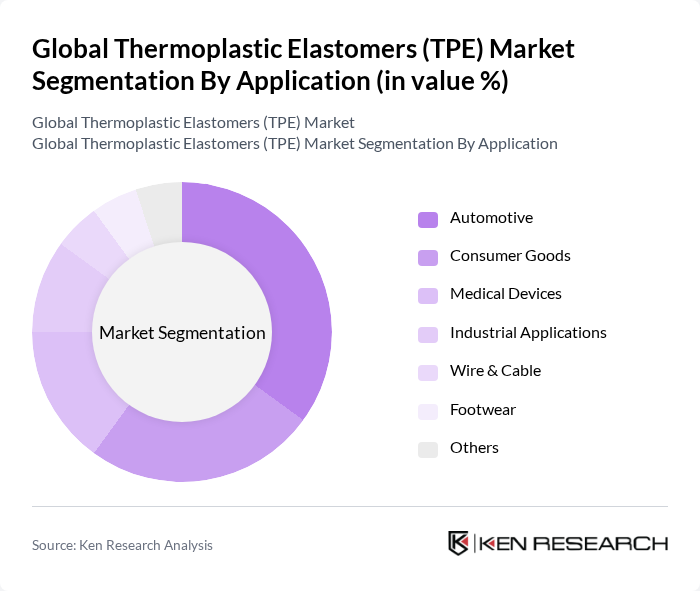

By Application:The applications of TPEs are diverse, including automotive, consumer goods, medical devices, industrial applications, wire & cable, footwear, and others. The automotive sector is the leading application area, driven by the demand for lightweight materials that enhance fuel efficiency and reduce emissions. TPEs are increasingly used in automotive interiors, exterior components, and seals due to their durability and flexibility, making them a preferred choice for manufacturers. Other major application segments include consumer goods, medical devices, and industrial applications, reflecting the broad utility of TPEs across multiple industries .

The Global Thermoplastic Elastomers (TPE) Market is characterized by a dynamic mix of regional and international players. Leading participants such as BASF SE, Kraton Corporation, LG Chem Ltd., Dow Inc., Mitsubishi Chemical Corporation, Huntsman Corporation, Wacker Chemie AG, RTP Company, Avient Corporation, KRAIBURG TPE GmbH & Co. KG, Elastron Kimya A.?., Sika AG, Solvay S.A., Eastman Chemical Company, Trelleborg AB, Arkema S.A., Asahi Kasei Corporation, Celanese Corporation, Covestro AG, DuPont de Nemours, Inc., Mitsui Chemicals, Inc., Evonik Industries AG, SIBUR, Versalis S.p.A., JSR Corporation, Kuraray Co., Ltd., LCY Chemical Corp., SK Chemicals, Tosoh Corporation, TSRC Corporation, Interplast contribute to innovation, geographic expansion, and service delivery in this space.

The future of the TPE market appears promising, driven by increasing demand for sustainable materials and technological advancements. As industries prioritize eco-friendly solutions, TPEs are likely to gain traction due to their recyclability and versatility. Additionally, the integration of smart technologies in TPE applications is expected to enhance product functionality. The market is also poised for growth as manufacturers explore innovative formulations to meet evolving consumer preferences and regulatory requirements, ensuring a competitive edge in the industry.

| Segment | Sub-Segments |

|---|---|

| By Type | Styrenic Block Copolymers (SBC) Thermoplastic Polyolefins (TPO) Thermoplastic Polyurethanes (TPU) Thermoplastic Vulcanizates (TPV) Thermoplastic Copolyesters (TPC) Others |

| By Application | Automotive Consumer Goods Medical Devices Industrial Applications Wire & Cable Footwear Others |

| By End-User | Automotive Industry Electronics & Electrical Healthcare & Medical Construction & Infrastructure Consumer Products Others |

| By Sales Channel | Direct Sales Distributors Online Sales Retail Others |

| By Region | North America Europe Asia-Pacific Latin America Middle East & Africa |

| By Price Range | Low Price Mid Price High Price |

| By Product Form | Granules Pellets Sheets Films Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Automotive Applications of TPE | 100 | Product Engineers, R&D Managers |

| Medical Device Manufacturing | 60 | Quality Assurance Managers, Regulatory Affairs Specialists |

| Consumer Goods Sector | 70 | Brand Managers, Product Development Leads |

| Construction and Building Materials | 50 | Procurement Managers, Project Engineers |

| Adhesives and Sealants Market | 40 | Technical Sales Representatives, Application Engineers |

The Global Thermoplastic Elastomers (TPE) Market is currently valued at approximately USD 26 billion, driven by the increasing demand for lightweight and flexible materials across various industries, including automotive, healthcare, and consumer goods.