Region:Asia

Author(s):Dev

Product Code:KRAD7654

Pages:81

Published On:December 2025

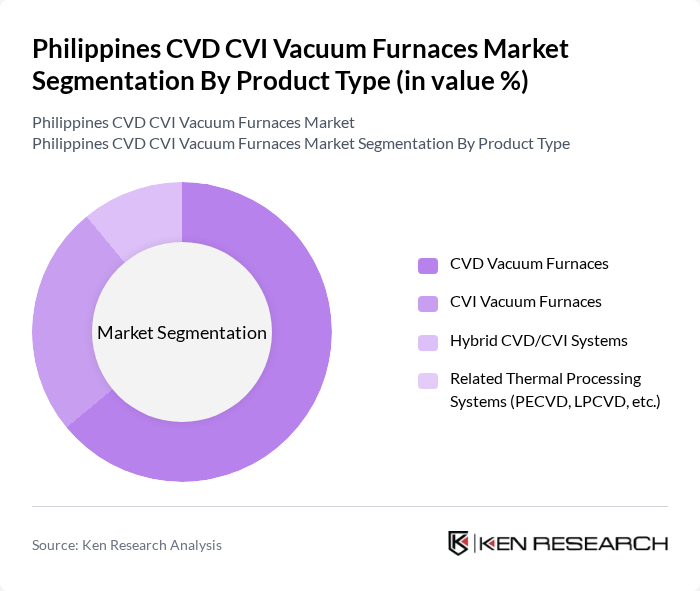

By Product Type:The product type segmentation includes various categories such as CVD Vacuum Furnaces, CVI Vacuum Furnaces, Hybrid CVD/CVI Systems, and Related Thermal Processing Systems (PECVD, LPCVD, etc.). Among these, CVD Vacuum Furnaces are leading the market due to their extensive application in semiconductor manufacturing and surface coating processes. The demand for high-quality thin films and coatings in electronics and aerospace industries drives the growth of this sub-segment. The increasing adoption of advanced materials and technologies further supports the dominance of CVD systems in the market.

By Orientation:The orientation segmentation includes Vertical Furnaces and Horizontal Furnaces. Vertical Furnaces are currently dominating the market due to their space-saving design and efficiency in processing materials. They are particularly favored in semiconductor and electronics manufacturing, where precision and quality are paramount. The trend towards miniaturization in electronics further enhances the demand for vertical systems, making them a preferred choice among manufacturers.

The Philippines CVD CVI Vacuum Furnaces Market is characterized by a dynamic mix of regional and international players. Leading participants such as CVD Equipment Corporation, PVA TePla AG, ULVAC, Inc., Nabertherm GmbH, ECM Technologies, Ipsen International GmbH, SECO/WARWICK S.A., AET Technologies, Linn High Therm GmbH, Oerlikon Balzers Coating (Philippines), Inc., Linde plc, Thermo Fisher Scientific Inc., ULVAC Philippines, Inc., Inductotherm Group, VTC Vacuum Technology Corporation contribute to innovation, geographic expansion, and service delivery in this space.

The future of the Philippines CVD CVI vacuum furnaces market appears promising, driven by ongoing technological advancements and a robust manufacturing sector. As industries increasingly prioritize energy efficiency and sustainability, vacuum furnace technology will likely play a crucial role in meeting these demands. Furthermore, the government's support for manufacturing growth and innovation will enhance the competitive landscape, encouraging more companies to adopt advanced manufacturing technologies, including vacuum furnaces, to improve productivity and product quality.

| Segment | Sub-Segments |

|---|---|

| By Product Type | CVD Vacuum Furnaces CVI Vacuum Furnaces Hybrid CVD/CVI Systems Related Thermal Processing Systems (PECVD, LPCVD, etc.) |

| By Orientation | Vertical Furnaces Horizontal Furnaces |

| By Operation Mode | Batch Furnaces Continuous / In-line Furnaces |

| By Key End-Use Industry | Semiconductors & Electronics Manufacturing Aerospace & Defense Automotive & EV Components Industrial Machinery & Tooling Medical & Dental Devices Research Institutes & Universities |

| By Process Application | Thin-Film Coatings & Surface Engineering Ceramic Matrix Composites (CMC) & Advanced Composites Diffusion, Brazing & Heat Treatment Additive Manufacturing Post-Processing Others |

| By Material Processed | Metals & Alloys Technical Ceramics Carbon & Graphite Composites & CMCs Others |

| By Furnace Size / Capacity | R&D / Laboratory-Scale Systems Pilot-Scale Systems Production-Scale Systems |

| By Region | Luzon (including Metro Manila) Visayas Mindanao |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Aerospace Manufacturing | 100 | Production Managers, Quality Assurance Engineers |

| Automotive Component Production | 80 | Supply Chain Managers, Technical Directors |

| Electronics and Semiconductor Fabrication | 70 | Process Engineers, R&D Managers |

| Advanced Materials Development | 60 | Material Scientists, Product Development Leads |

| Research Institutions and Universities | 40 | Academic Researchers, Industry Collaborators |

The Philippines CVD CVI Vacuum Furnaces Market is valued at approximately USD 150 million, reflecting a five-year historical analysis. This growth is driven by increasing demand in sectors like semiconductors, aerospace, and automotive.