Region:Asia

Author(s):Rebecca

Product Code:KRAD6229

Pages:100

Published On:December 2025

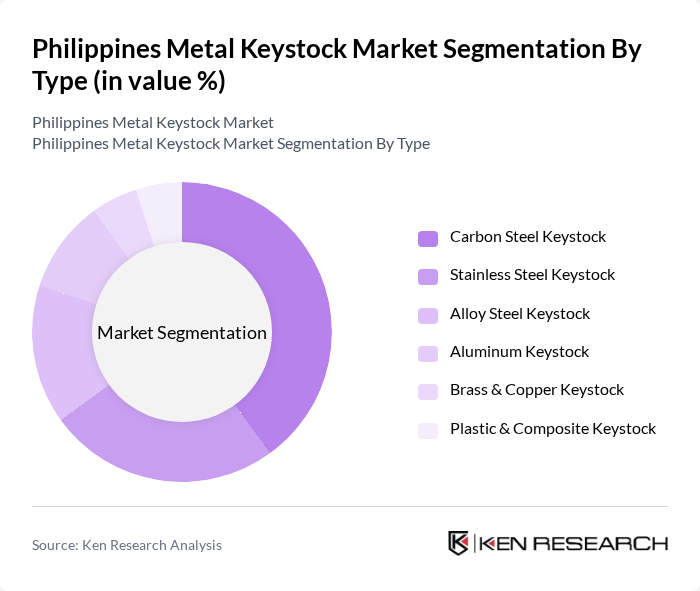

By Type:The market is segmented into various types of metal keystocks, including Carbon Steel Keystock, Stainless Steel Keystock, Alloy Steel Keystock, Aluminum Keystock, Brass & Copper Keystock, and Plastic & Composite Keystock. Among these, Carbon Steel Keystock is the most dominant due to its widespread use in heavy machinery and automotive applications, driven by its strength and cost-effectiveness. Stainless Steel Keystock follows closely, favored for its corrosion resistance in marine and industrial environments.

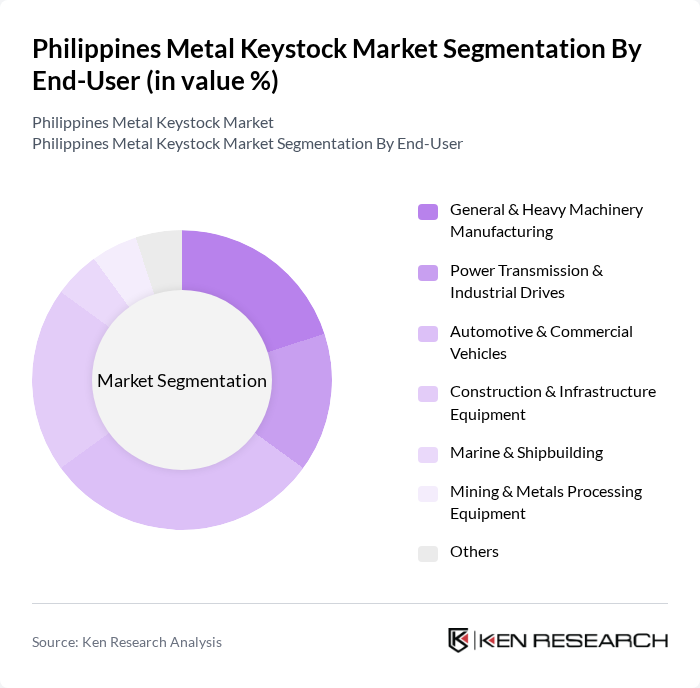

By End-User:The end-user segmentation includes General & Heavy Machinery Manufacturing, Power Transmission & Industrial Drives, Automotive & Commercial Vehicles, Construction & Infrastructure Equipment, Marine & Shipbuilding, Mining & Metals Processing Equipment, and Others. The Automotive & Commercial Vehicles segment leads the market, driven by the increasing production of vehicles and the demand for reliable components. The Construction & Infrastructure Equipment segment is also significant, reflecting the ongoing infrastructure development in the Philippines.

The Philippines Metal Keystock Market is characterized by a dynamic mix of regional and international players. Leading participants such as SteelAsia Manufacturing Corporation, TKC Metals Corporation, Philippine Steel Coating Corporation, Capitol Steel Corporation, PAG-ASA Steel Works, Inc., Puyat Steel Corporation, Metalink Manufacturing Corporation, Sonic Steel Industries Inc., Cathay Metal Corporation, Power Steel Corporation, Pioneer Steel Corporation, Regan Industrial Sales Inc., Supreme Steel Pipe Corporation, Manly Plastics, Inc., Triumph Sheeting & Steel Corporation contribute to innovation, geographic expansion, and service delivery in this space.

The Philippines metal keystock market is poised for significant growth, driven by increasing demand from construction and manufacturing sectors, alongside technological advancements. As the government continues to invest in infrastructure, the need for high-quality metal products will rise. Additionally, the shift towards sustainable practices and Industry 4.0 technologies will reshape production processes, enhancing efficiency and customization. Companies that adapt to these trends will likely capture a larger market share and drive innovation in the industry.

| Segment | Sub-Segments |

|---|---|

| By Type | Carbon Steel Keystock Stainless Steel Keystock Alloy Steel Keystock Aluminum Keystock Brass & Copper Keystock Plastic & Composite Keystock |

| By End-User | General & Heavy Machinery Manufacturing Power Transmission & Industrial Drives Automotive & Commercial Vehicles Construction & Infrastructure Equipment Marine & Shipbuilding Mining & Metals Processing Equipment Others |

| By Application | Shaft-Hub Connections (Power Transmission) Gearboxes & Speed Reducers Pumps, Compressors & Blowers Conveyor Systems & Material Handling Equipment Agricultural & Construction Machinery Components Others |

| By Distribution Channel | Direct Sales to OEMs Industrial Distributors & Stockists Online Industrial Marketplaces Retail / Hardware & Industrial Supply Stores Others |

| By Material Grade | Low-Carbon Steel (e.g., 1018, 1020) Medium-Carbon & Alloy Steel (e.g., 1045, 1144) Stainless Steel Grades (e.g., 304, 316) Non-Ferrous Grades (Aluminum, Brass, Copper) Others |

| By Region | Luzon Visayas Mindanao Others |

| By Customer Type | OEMs Maintenance, Repair & Overhaul (MRO) Customers Project Contractors & EPCs Traders & Distributors Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Construction Industry Metal Keystock Usage | 100 | Project Managers, Procurement Officers |

| Automotive Manufacturing Applications | 80 | Production Managers, Quality Control Engineers |

| Machinery and Equipment Sector Insights | 70 | Operations Managers, Technical Directors |

| Metal Keystock Distribution Channels | 60 | Sales Managers, Supply Chain Coordinators |

| End-user Feedback on Metal Keystock Performance | 90 | Maintenance Supervisors, Engineering Managers |

The Philippines Metal Keystock Market is valued at approximately USD 1 million, reflecting a five-year historical analysis. This valuation is driven by increasing demand across various sectors, including automotive, construction, and machinery manufacturing.