Region:Asia

Author(s):Rebecca

Product Code:KRAC8594

Pages:96

Published On:November 2025

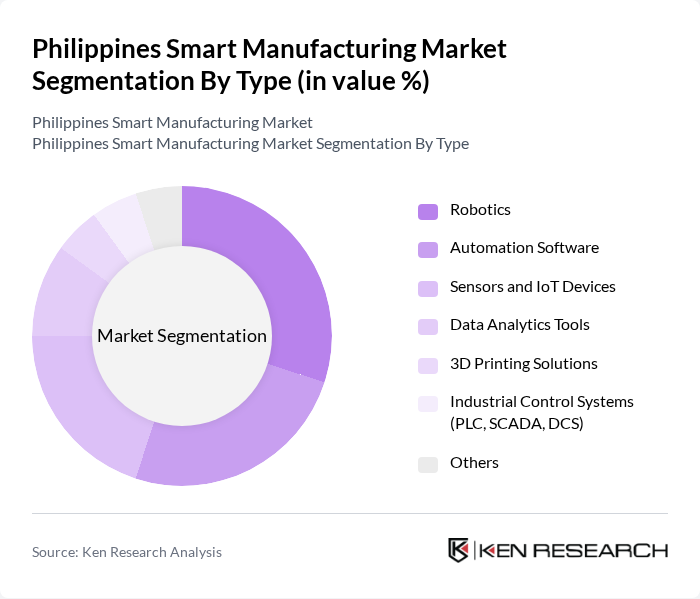

By Type:The market is segmented into Robotics, Automation Software, Sensors and IoT Devices, Data Analytics Tools, 3D Printing Solutions, Industrial Control Systems (PLC, SCADA, DCS), and Others. Robotics and Automation Software are leading segments, driven by their role in boosting productivity, precision, and operational efficiency. The adoption of industrial robots and automation platforms is accelerating, particularly in automotive and electronics manufacturing, as companies seek to reduce labor costs, improve quality, and enable predictive maintenance. Sensors and IoT Devices are increasingly deployed for real-time monitoring, while Data Analytics Tools support advanced process optimization and decision-making .

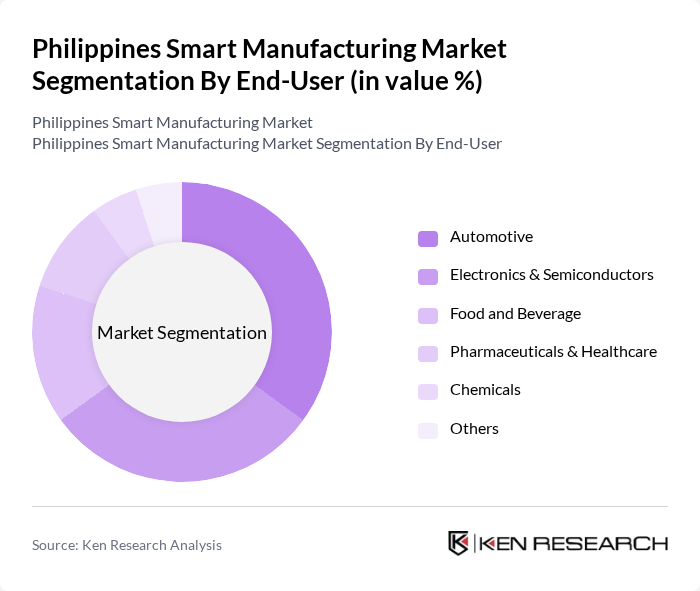

By End-User:The end-user segmentation includes Automotive, Electronics & Semiconductors, Food and Beverage, Pharmaceuticals & Healthcare, Chemicals, and Others. Automotive and Electronics & Semiconductors are the largest contributors, driven by the need for precision manufacturing, smart automation, and the rising demand for electric vehicles and consumer electronics. Food and Beverage, Pharmaceuticals & Healthcare, and Chemicals sectors are also increasing adoption of smart manufacturing for quality control, traceability, and regulatory compliance. The Others segment includes textiles, aerospace, and emerging industries adopting Industry 4.0 solutions .

The Philippines Smart Manufacturing Market is characterized by a dynamic mix of regional and international players. Leading participants such as Siemens Philippines, ABB Philippines, Rockwell Automation Philippines, Mitsubishi Electric Asia (Philippines Branch), Honeywell Philippines Inc., Schneider Electric Philippines, Yokogawa Philippines, Inc., Emerson Electric Asia Ltd. (Philippines), FANUC Philippines Corporation, Bosch Rexroth Philippines Inc., Omron Electronics Philippines, Inc., KUKA Robotics (Asia Pacific) Pte. Ltd. – Philippines, National Instruments Philippines (NI Philippines), GE Digital (Philippines), Cognex Corporation (Philippines) contribute to innovation, geographic expansion, and service delivery in this space.

The future of the smart manufacturing market in the Philippines appears promising, driven by ongoing technological advancements and government support. In future, the integration of AI and machine learning is expected to revolutionize production processes, enhancing efficiency and reducing waste. Additionally, the focus on sustainability will likely lead to increased investments in green manufacturing practices, aligning with global trends. As companies adapt to these changes, the market is poised for significant growth, fostering innovation and competitiveness.

| Segment | Sub-Segments |

|---|---|

| By Type | Robotics Automation Software Sensors and IoT Devices Data Analytics Tools D Printing Solutions Industrial Control Systems (PLC, SCADA, DCS) Others |

| By End-User | Automotive Electronics & Semiconductors Food and Beverage Pharmaceuticals & Healthcare Chemicals Others |

| By Industry Vertical | Aerospace & Defense Consumer Goods Heavy Machinery & Equipment Textile & Apparel Energy & Utilities Others |

| By Technology | Cloud Computing Edge Computing Artificial Intelligence (AI) Machine Learning (ML) Industrial Internet of Things (IIoT) Augmented Reality (AR) & Virtual Reality (VR) Cybersecurity Solutions Others |

| By Application | Predictive Maintenance Quality Control & Inspection Supply Chain & Inventory Management Production Planning & Scheduling Energy Management Asset Tracking Others |

| By Investment Source | Private Investments Government Funding Foreign Direct Investment (FDI) Public-Private Partnerships (PPP) Multilateral Development Agencies Others |

| By Policy Support | Tax Incentives Grants for Technology Adoption Training Programs for Workforce Development Regulatory Support for Innovation Digital Infrastructure Initiatives Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Automotive Manufacturing Sector | 100 | Production Managers, Technology Officers |

| Electronics Manufacturing Sector | 80 | Operations Managers, R&D Heads |

| Consumer Goods Manufacturing Sector | 70 | Supply Chain Managers, Quality Assurance Leads |

| Textile Manufacturing Sector | 60 | Process Engineers, Sustainability Managers |

| Food and Beverage Manufacturing Sector | 90 | Plant Managers, Compliance Officers |

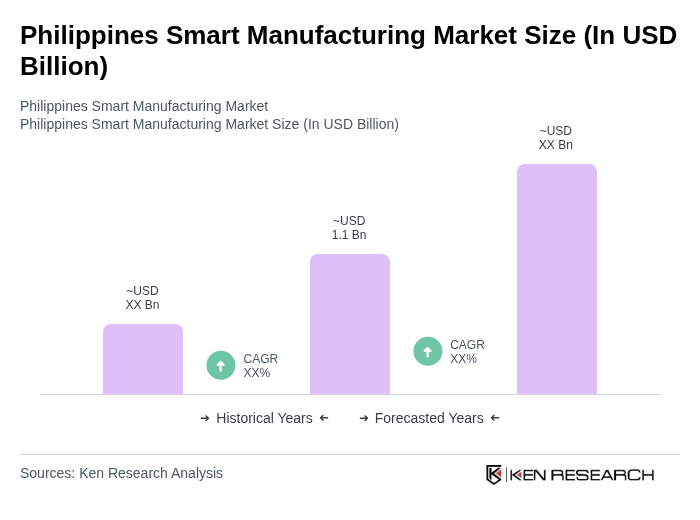

The Philippines Smart Manufacturing Market is valued at approximately USD 1.1 billion, reflecting significant growth driven by the integration of AI, IoT, and automation technologies across various manufacturing sectors.