Region:Global

Author(s):Rebecca

Product Code:KRAA2439

Pages:94

Published On:August 2025

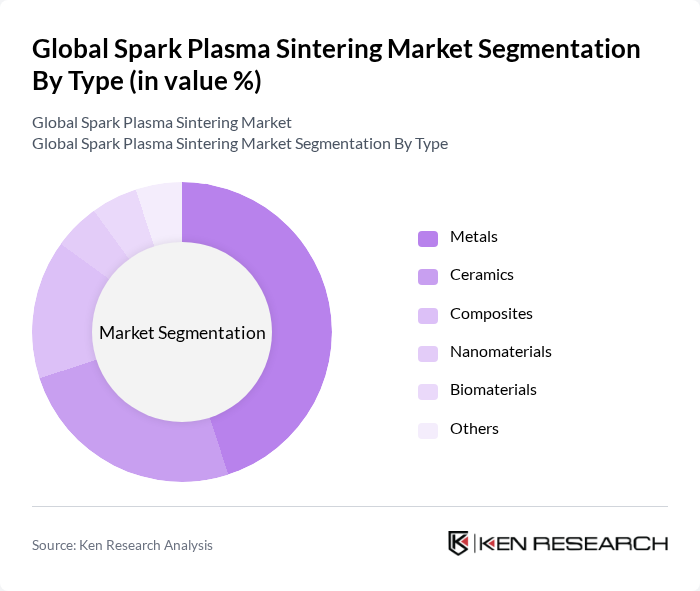

By Type:The market is segmented into various types, including Metals, Ceramics, Composites, Nanomaterials, Biomaterials, and Others. Among these,Metalsare the most dominant segment due to their extensive applications in aerospace, automotive, and industrial sectors. The demand for high-strength and lightweight metal components is driving the growth of this segment.CeramicsandCompositesare also gaining traction, particularly in specialized applications requiring high thermal and mechanical properties, such as cutting tools, wear-resistant components, and high-temperature structural materials. Nanomaterials and biomaterials are emerging segments, driven by advancements in medical devices and electronics .

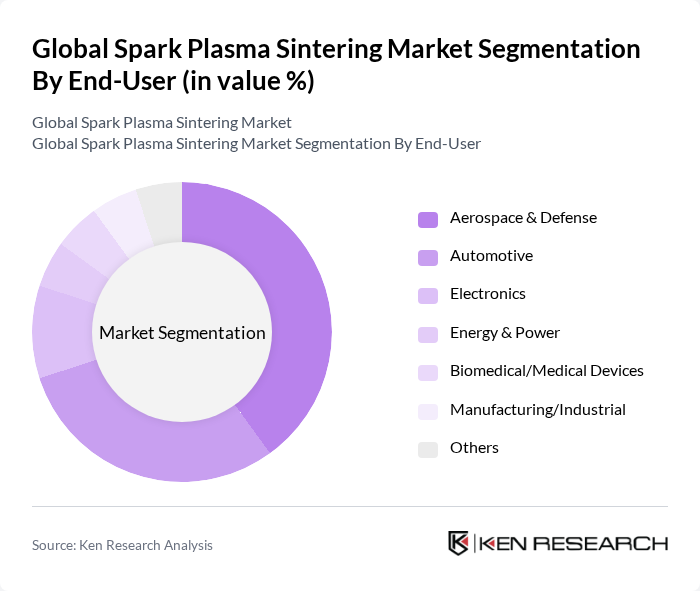

By End-User:The end-user segmentation includes Aerospace & Defense, Automotive, Electronics, Energy & Power, Biomedical/Medical Devices, Manufacturing/Industrial, and Others. TheAerospace & Defensesector is the leading end-user, driven by the need for lightweight, high-strength materials that can withstand extreme conditions. TheAutomotiveindustry follows closely, as manufacturers seek to enhance vehicle performance and fuel efficiency through advanced materials. Electronics and biomedical sectors are expanding due to the demand for miniaturized, high-performance components and medical implants. Energy & Power applications are growing, particularly in fuel cells and battery technologies .

The Global Spark Plasma Sintering Market is characterized by a dynamic mix of regional and international players. Leading participants such as FCT Systeme GmbH, Sumitomo Heavy Industries, Ltd., Dr. Sinter / Fuji Electronic Industrial Co., Ltd., Thermal Technology LLC, Sinter Land Inc., Shanghai Gehang Vacuum Technology Co., Ltd., Advanced Vacuum Systems, Inc., PVA TePla AG, Materials Research Furnaces, LLC, Nabertherm GmbH, EPSI NV, H.C. Starck GmbH, ALD Vacuum Technologies GmbH, Centorr Vacuum Industries, Inc., KCEI (Kobe Steel, Ltd. Group) contribute to innovation, geographic expansion, and service delivery in this space.

The future of the spark plasma sintering market appears promising, driven by ongoing technological advancements and increasing demand for high-performance materials. As industries prioritize sustainability, the integration of eco-friendly practices in manufacturing processes will likely gain traction. Furthermore, the collaboration between manufacturers and research institutions is expected to foster innovation, leading to the development of customized sintering solutions that cater to specific industry needs, enhancing overall market growth and competitiveness.

| Segment | Sub-Segments |

|---|---|

| By Type | Metals Ceramics Composites Nanomaterials Biomaterials Others |

| By End-User | Aerospace & Defense Automotive Electronics Energy & Power Biomedical/Medical Devices Manufacturing/Industrial Others |

| By Application | Tooling Structural Components Functional Parts Research and Development Additive Manufacturing Others |

| By Material Source | Domestic Suppliers International Suppliers Recycled Materials Others |

| By Distribution Channel | Direct Sales Distributors Online Sales Others |

| By Pricing Strategy | Premium Pricing Competitive Pricing Value-Based Pricing Others |

| By Region | North America Europe Asia-Pacific Latin America Middle East & Africa |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Aerospace Component Manufacturers | 100 | Production Managers, Quality Assurance Engineers |

| Automotive Parts Producers | 80 | Design Engineers, Supply Chain Managers |

| Electronics Device Manufacturers | 90 | Product Development Managers, R&D Directors |

| Biomedical Material Suppliers | 60 | Regulatory Affairs Specialists, Material Scientists |

| Research Institutions and Universities | 50 | Academic Researchers, Graduate Students in Materials Science |

The Global Spark Plasma Sintering Market is valued at approximately USD 1.1 billion, reflecting significant growth driven by advancements in material science and increasing demand for high-performance materials across various industries, including automotive, aerospace, and electronics.