Region:Global

Author(s):Rebecca

Product Code:KRAA2856

Pages:88

Published On:August 2025

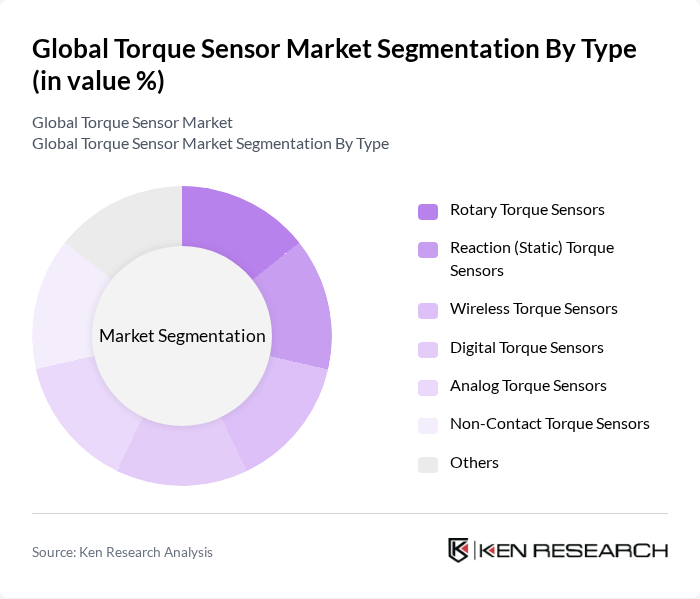

By Type:The torque sensor market is segmented into various types, including Rotary Torque Sensors, Reaction (Static) Torque Sensors, Wireless Torque Sensors, Digital Torque Sensors, Analog Torque Sensors, Non-Contact Torque Sensors, and Others. Among these, Rotary Torque Sensors are the most widely used due to their versatility and high accuracy in measuring torque in rotating applications. The increasing automation in industries and the adoption of electric powertrains and robotics have further boosted the demand for these sensors, making them a preferred choice for manufacturers .

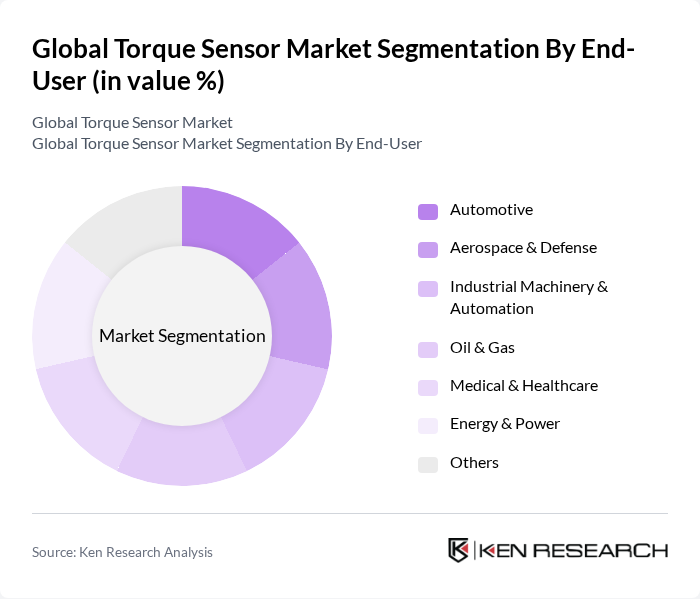

By End-User:The end-user segmentation includes Automotive, Aerospace & Defense, Industrial Machinery & Automation, Oil & Gas, Medical & Healthcare, Energy & Power, and Others. The Automotive sector is the leading end-user of torque sensors, driven by the increasing need for precision in vehicle performance, safety, and the adoption of electric vehicles and advanced driver-assistance systems (ADAS). Industrial automation and robotics are also rapidly expanding end-user segments, reflecting the growing integration of torque sensors in smart manufacturing and process control .

The Global Torque Sensor Market is characterized by a dynamic mix of regional and international players. Leading participants such as Honeywell International Inc., Siemens AG, Kistler Holding AG, HBM (Hottinger Brüel & Kjær, part of Spectris plc), TE Connectivity Ltd., Vishay Precision Group, Inc., Flintec Group AB, Omega Engineering, Inc., FUTEK Advanced Sensor Technology, Inc., PCB Piezotronics, Inc. (MTS Systems Corporation), Strain Measurement Devices, Inc., Applied Measurements Ltd., Ametek, Inc., Datum Electronics Ltd. (Indutrade AB), and Crane Electronics Ltd. contribute to innovation, geographic expansion, and service delivery in this space.

The future of the torque sensor market appears promising, driven by technological advancements and increasing demand across various sectors. The integration of IoT technologies is expected to enhance sensor capabilities, allowing for real-time data analysis and improved operational efficiency. Additionally, the growing focus on renewable energy sources will likely create new applications for torque sensors, particularly in wind and solar energy systems, fostering innovation and market expansion in future.

| Segment | Sub-Segments |

|---|---|

| By Type | Rotary Torque Sensors Reaction (Static) Torque Sensors Wireless Torque Sensors Digital Torque Sensors Analog Torque Sensors Non-Contact Torque Sensors Others |

| By End-User | Automotive Aerospace & Defense Industrial Machinery & Automation Oil & Gas Medical & Healthcare Energy & Power Others |

| By Application | Engine & Powertrain Testing Robotics & Automation Research & Development Quality Control & Inspection Process Control Structural Testing Others |

| By Distribution Channel | Direct Sales Online Retail Distributors/VARs System Integrators Others |

| By Region | North America Europe Asia-Pacific Latin America Middle East & Africa |

| By Price Range | Low Range Mid Range High Range |

| By Technology | Strain Gauge Technology Magnetostrictive Technology Optical Technology Surface Acoustic Wave (SAW) Technology MEMS Technology Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Automotive Torque Sensor Applications | 100 | Automotive Engineers, Product Development Managers |

| Aerospace Torque Measurement | 70 | Aerospace Engineers, Quality Assurance Managers |

| Industrial Machinery Sensors | 80 | Manufacturing Engineers, Operations Managers |

| Research & Development in Sensor Technology | 60 | R&D Managers, Technical Directors |

| Market Trends in Torque Sensors | 50 | Market Analysts, Business Development Executives |

The Global Torque Sensor Market is valued at approximately USD 11 billion, driven by the increasing demand for precision measurement across various industries, including automotive, aerospace, and industrial automation.