Region:Asia

Author(s):Rebecca

Product Code:KRAC8477

Pages:91

Published On:November 2025

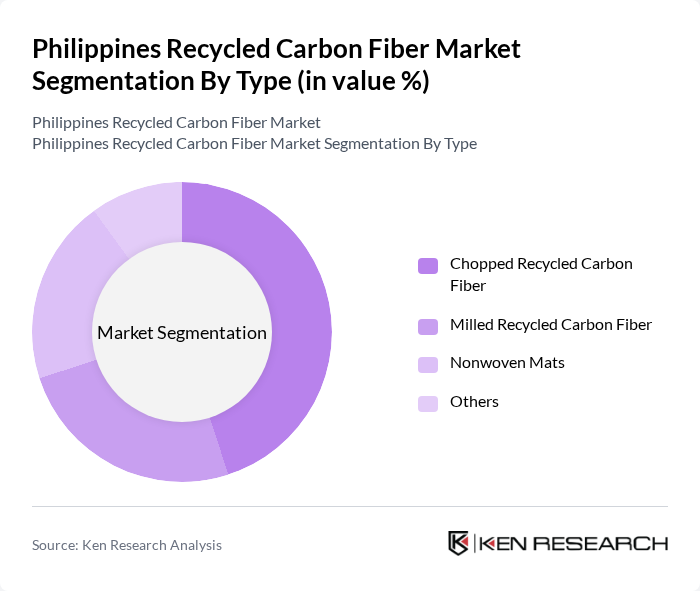

By Type:The market is segmented into Chopped Recycled Carbon Fiber, Milled Recycled Carbon Fiber, Nonwoven Mats, and Others. Chopped Recycled Carbon Fiber is gaining significant traction due to its versatility, ease of processing, and cost-effectiveness, making it a preferred choice in automotive, construction, and consumer goods applications. Milled Recycled Carbon Fiber is increasingly adopted for its ability to enhance mechanical and electrical properties in high-precision applications such as electronics and coatings. Nonwoven Mats are utilized in wind energy and infrastructure projects for their structural reinforcement capabilities .

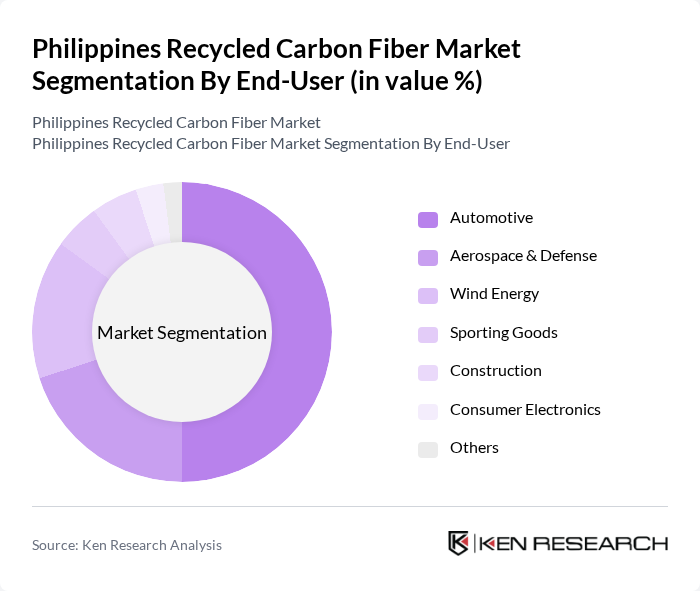

By End-User:The end-user segmentation includes Automotive, Aerospace & Defense, Wind Energy, Sporting Goods, Construction, Consumer Electronics, and Others. The Automotive sector is the leading end-user, driven by the increasing adoption of lightweight and sustainable materials to enhance fuel efficiency and reduce emissions. Aerospace & Defense is a major segment due to the demand for high-performance, lightweight composites. Wind Energy is experiencing rapid growth as recycled carbon fiber is increasingly used in turbine blade reinforcement and related infrastructure .

The Philippines Recycled Carbon Fiber Market is characterized by a dynamic mix of regional and international players. Leading participants such as Carbon Conversions, Inc., Toray Industries, Inc., SGL Carbon SE, Hexcel Corporation, Mitsubishi Chemical Group Corporation, Solvay S.A., Teijin Limited, Zoltek Companies, Inc. (A Toray Company), ELG Carbon Fibre Ltd., Carbon Fiber Recycling, Inc., Vartega Inc., Procotex Corporation SA, Shocker Composites LLC, Gen 2 Carbon Limited, BASF SE contribute to innovation, geographic expansion, and service delivery in this space.

The future of the recycled carbon fiber market in the Philippines appears promising, driven by increasing environmental awareness and government support for sustainable practices. As industries adopt circular economy principles, the demand for recycled materials is expected to rise significantly. Furthermore, advancements in recycling technologies will likely enhance the quality and cost-effectiveness of recycled carbon fibers, making them more appealing to manufacturers. This evolving landscape presents a unique opportunity for growth and innovation in the sector.

| Segment | Sub-Segments |

|---|---|

| By Type | Chopped Recycled Carbon Fiber Milled Recycled Carbon Fiber Nonwoven Mats Others |

| By End-User | Automotive Aerospace & Defense Wind Energy Sporting Goods Construction Consumer Electronics Others |

| By Application | Structural Components Interior Components Composite Materials Conductive Plastics, Coatings & Adhesives Others |

| By Manufacturing Process | Mechanical Recycling Chemical Recycling Thermal Recycling Others |

| By Source of Raw Material | Automotive Scrap Aerospace Scrap Wind Turbine Blades Others |

| By Distribution Channel | Direct Sales Online Sales Distributors Others |

| By Region | Luzon Visayas Mindanao |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Carbon Fiber Manufacturers | 60 | Production Managers, Quality Control Officers |

| Recycling Facility Operators | 50 | Facility Managers, Operations Supervisors |

| End-User Industries (Automotive) | 40 | Procurement Managers, Product Development Engineers |

| Research Institutions | 40 | Research Scientists, Environmental Policy Analysts |

| Government Regulatory Bodies | 40 | Policy Makers, Environmental Compliance Officers |

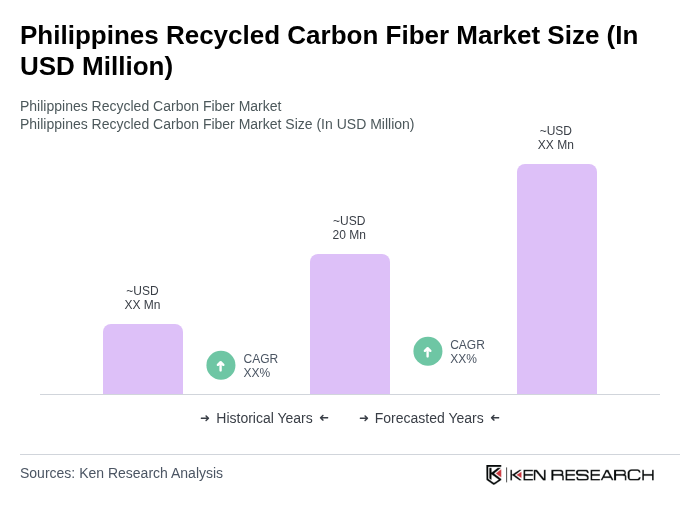

The Philippines Recycled Carbon Fiber Market is valued at approximately USD 20 million, reflecting a growing trend towards sustainable materials in various sectors, including automotive, aerospace, and construction.