Region:Middle East

Author(s):Shubham

Product Code:KRAB8038

Pages:92

Published On:October 2025

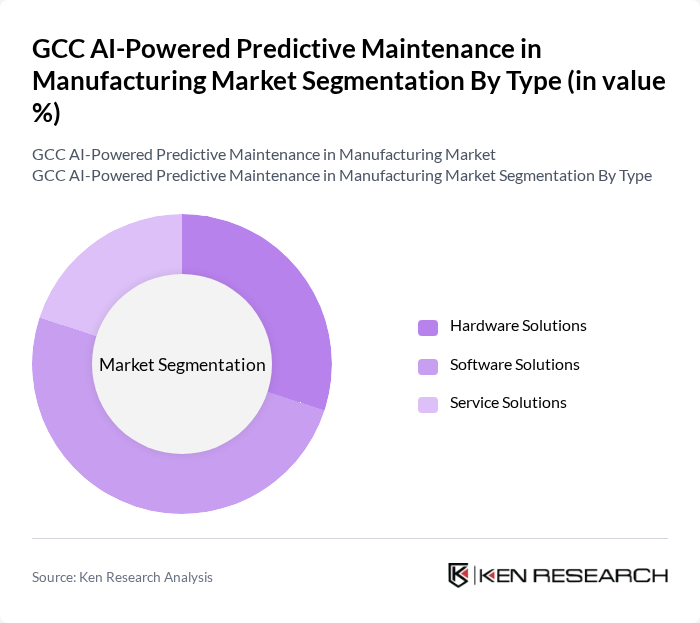

By Type:The segmentation by type includes Hardware Solutions, Software Solutions, and Service Solutions. Among these, Software Solutions dominate the market due to the increasing demand for advanced analytics and machine learning capabilities that enhance predictive maintenance strategies. The trend towards digital transformation in manufacturing has led to a surge in software adoption, enabling real-time monitoring and data-driven decision-making.

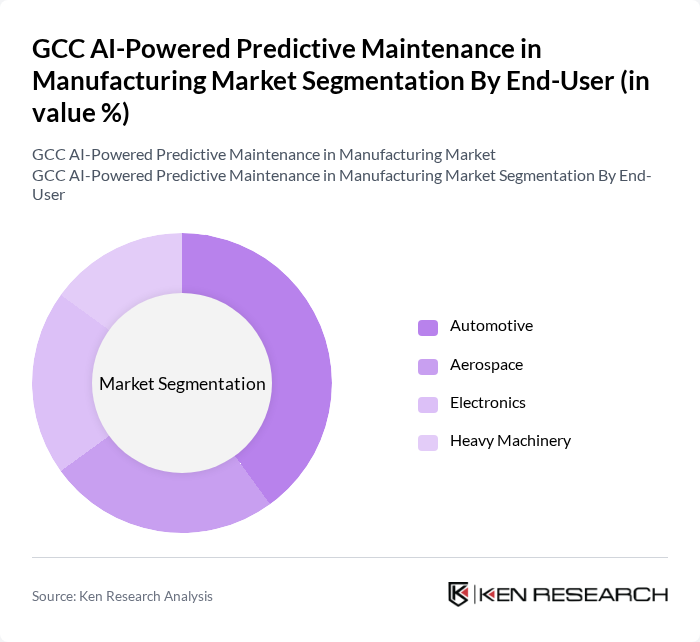

By End-User:The end-user segmentation includes Automotive, Aerospace, Electronics, and Heavy Machinery. The Automotive sector is the leading end-user, driven by the need for enhanced operational efficiency and reduced downtime. Manufacturers in this sector are increasingly adopting predictive maintenance solutions to optimize production processes and improve vehicle reliability, making it a key area of growth.

The GCC AI-Powered Predictive Maintenance in Manufacturing Market is characterized by a dynamic mix of regional and international players. Leading participants such as Siemens AG, General Electric Company, Honeywell International Inc., IBM Corporation, Schneider Electric SE, Rockwell Automation, Inc., PTC Inc., SAP SE, ABB Ltd., Emerson Electric Co., Yokogawa Electric Corporation, Mitsubishi Electric Corporation, Hitachi, Ltd., Cisco Systems, Inc., Dell Technologies Inc. contribute to innovation, geographic expansion, and service delivery in this space.

The future of the GCC AI-powered predictive maintenance market appears promising, driven by technological advancements and increasing investments in smart manufacturing. As companies prioritize operational efficiency and sustainability, the adoption of AI and IoT technologies is expected to accelerate. Furthermore, the growing emphasis on data-driven decision-making will likely enhance predictive maintenance capabilities, leading to improved asset management and reduced operational costs. The region's commitment to diversifying its economy will further support the integration of innovative solutions in manufacturing processes.

| Segment | Sub-Segments |

|---|---|

| By Type | Hardware Solutions Software Solutions Service Solutions |

| By End-User | Automotive Aerospace Electronics Heavy Machinery |

| By Application | Equipment Monitoring Predictive Analytics Condition-Based Maintenance |

| By Component | Sensors Software Platforms Data Analytics Tools |

| By Sales Channel | Direct Sales Distributors Online Sales |

| By Distribution Mode | Retail Distribution Wholesale Distribution E-commerce |

| By Others | Custom Solutions Niche Applications |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Oil & Gas Sector Maintenance Strategies | 100 | Maintenance Managers, Operations Directors |

| Automotive Manufacturing Predictive Maintenance | 80 | Production Engineers, Quality Control Managers |

| Consumer Goods Manufacturing Insights | 70 | Supply Chain Managers, IT Directors |

| Pharmaceutical Manufacturing Technologies | 60 | Regulatory Affairs Managers, Process Engineers |

| Electronics Manufacturing Maintenance Practices | 90 | Technical Managers, Data Analysts |

The GCC AI-Powered Predictive Maintenance in Manufacturing Market is valued at approximately USD 1.2 billion, reflecting a significant growth driven by the adoption of IoT technologies and the need for operational efficiency in manufacturing processes.