Region:Global

Author(s):Geetanshi

Product Code:KRAA2743

Pages:94

Published On:August 2025

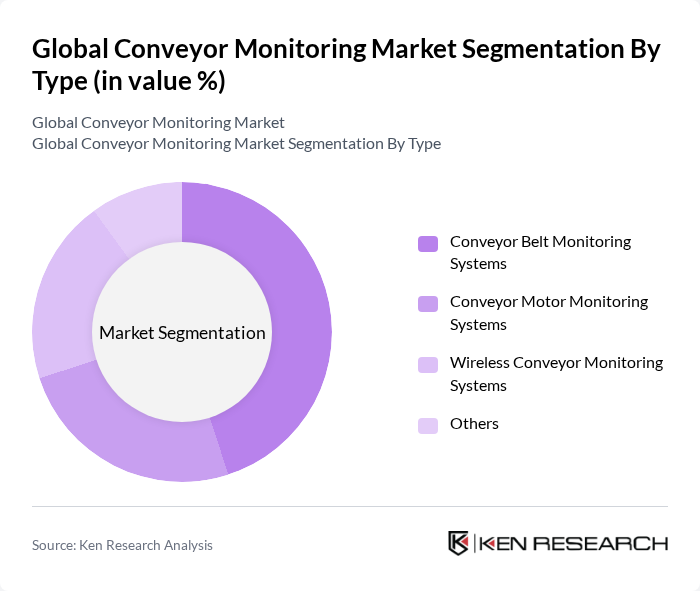

By Type:The market is segmented into various types, including Conveyor Belt Monitoring Systems, Conveyor Motor Monitoring Systems, Wireless Conveyor Monitoring Systems, and Others. Among these, Conveyor Belt Monitoring Systems are leading the market due to their critical role in ensuring the smooth operation of conveyor systems, which are essential in manufacturing and logistics. The increasing focus on predictive maintenance and operational efficiency has further boosted the adoption of these systems .

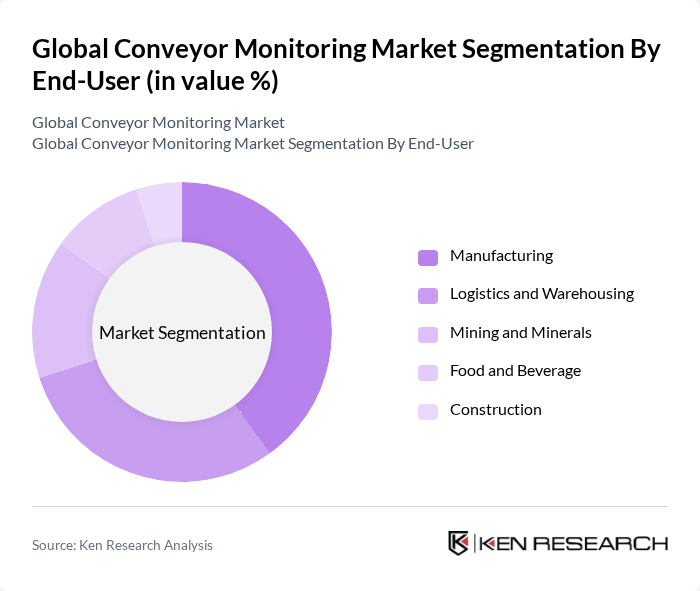

By End-User:The end-user segmentation includes Manufacturing, Logistics and Warehousing, Mining and Minerals, Food and Beverage, Construction, and Others. The Manufacturing sector is the dominant end-user, driven by the need for efficient material handling and quality control processes. The increasing automation in manufacturing facilities has led to a higher demand for conveyor monitoring systems, ensuring operational efficiency and reducing downtime .

The Global Conveyor Monitoring Market is characterized by a dynamic mix of regional and international players. Leading participants such as Siemens AG, Honeywell International Inc., Rockwell Automation, Inc., Schneider Electric SE, Emerson Electric Co., Mitsubishi Electric Corporation, Bosch Rexroth AG, Yokogawa Electric Corporation, ABB Ltd., SICK AG, Omron Corporation, KUKA AG, B&R Industrial Automation GmbH, Beltscan Systems Pty Ltd., CBG Conveyor Belt Gateway GmbH, Mighty Lube Systematic Lubrication, Inc., Tsubaki Nakashima Co., Ltd. contribute to innovation, geographic expansion, and service delivery in this space .

The future of the conveyor monitoring market in None is poised for significant transformation, driven by technological advancements and evolving industry needs. As companies increasingly adopt IoT and AI technologies, real-time monitoring capabilities will enhance operational efficiency and predictive maintenance strategies. Furthermore, the expansion into emerging markets will provide new growth avenues, allowing businesses to leverage innovative solutions that meet local demands while adhering to sustainability practices and regulatory requirements.

| Segment | Sub-Segments |

|---|---|

| By Type | Conveyor Belt Monitoring Systems Conveyor Motor Monitoring Systems Wireless Conveyor Monitoring Systems Others |

| By End-User | Manufacturing Logistics and Warehousing Mining and Minerals Food and Beverage Construction Others |

| By Component | Sensors Software & Analytics Control Systems Cameras & RFID Others |

| By Sales Channel | Direct Sales Distributors Online Sales Others |

| By Distribution Mode | Offline Distribution Online Distribution Hybrid Distribution Others |

| By Price Range | Low Price Range Mid Price Range High Price Range |

| By Application | Material Handling Quality Control Safety Monitoring Predictive Maintenance Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Manufacturing Sector Conveyor Systems | 120 | Operations Managers, Production Supervisors |

| Food & Beverage Industry Automation | 90 | Plant Managers, Quality Control Managers |

| Pharmaceutical Conveyor Applications | 70 | Regulatory Affairs Managers, Supply Chain Coordinators |

| Logistics and Warehousing Solutions | 100 | Logistics Managers, Warehouse Operations Managers |

| Retail Sector Conveyor Integration | 60 | Retail Operations Managers, Supply Chain Analysts |

The Global Conveyor Monitoring Market is valued at approximately USD 275 million, driven by the increasing demand for automation, predictive maintenance, and operational efficiency across various sectors such as manufacturing, mining, and logistics.