Region:Middle East

Author(s):Dev

Product Code:KRAC4182

Pages:91

Published On:October 2025

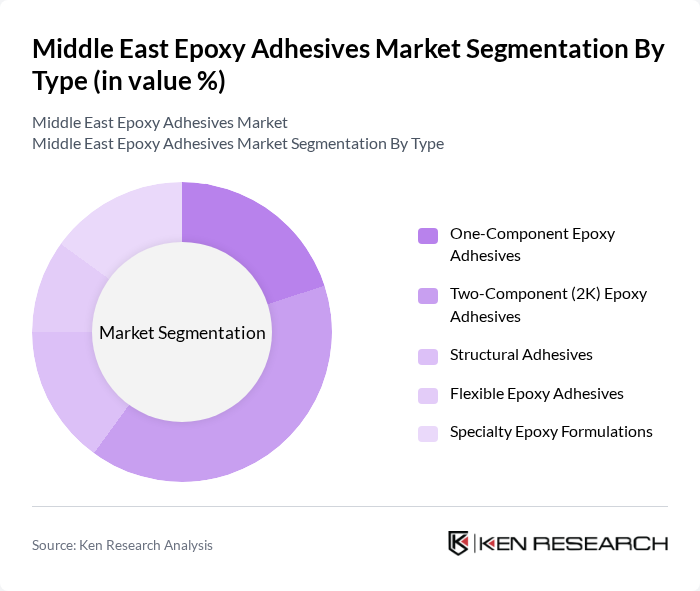

By Type:The epoxy adhesives market can be segmented into various types, including One-Component Epoxy Adhesives, Two-Component (2K) Epoxy Adhesives, Structural Adhesives, Flexible Epoxy Adhesives, and Specialty Epoxy Formulations. Among these, Two-Component (2K) Epoxy Adhesives are leading the market due to their superior bonding capabilities and versatility across multiple applications.

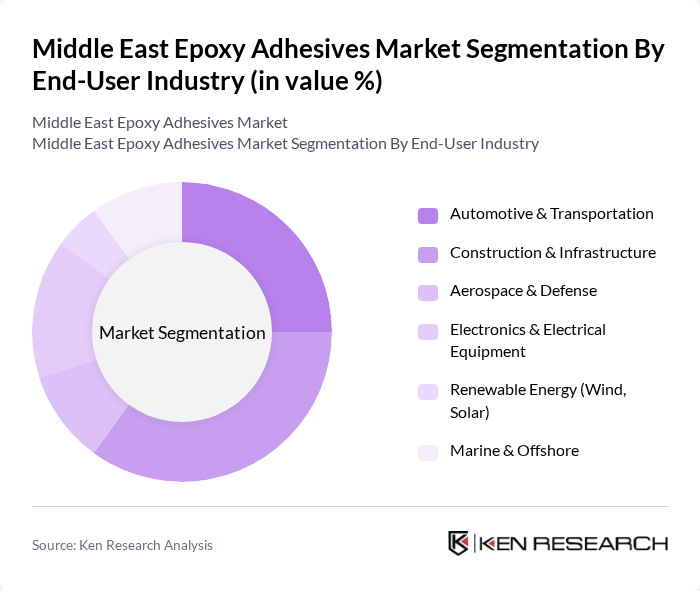

By End-User Industry:The market is also segmented by end-user industries, including Automotive & Transportation, Construction & Infrastructure, Aerospace & Defense, Electronics & Electrical Equipment, Renewable Energy (Wind, Solar), and Marine & Offshore. The Construction & Infrastructure sector is the dominant segment, driven by ongoing urban development and infrastructure projects across the region.

The Middle East Epoxy Adhesives Market is characterized by a dynamic mix of regional and international players. Leading participants such as Henkel AG & Co. KGaA, 3M Company, Sika AG, H.B. Fuller Company, Huntsman International LLC, Dow Inc., Wacker Chemie AG, RPM International Inc., Avery Dennison Corporation, PIDILITE Industries Limited, Lord Corporation, Arkema Group (Bostik Division), MasterBond Inc., Permabond LLC, Cytec Industries (Solvay Subsidiary) contribute to innovation, geographic expansion, and service delivery in this space.

The Middle East epoxy adhesives market is poised for significant growth, driven by increasing demand from key industries and a shift towards sustainable solutions. As infrastructure projects expand and automotive production rises, the need for high-performance adhesives will intensify. Additionally, technological advancements will continue to enhance product offerings, while regulatory compliance will shape market dynamics. Companies that invest in eco-friendly innovations and adapt to changing consumer preferences are likely to thrive in this evolving landscape, ensuring a robust market presence.

| Segment | Sub-Segments |

|---|---|

| By Type | One-Component Epoxy Adhesives Two-Component (2K) Epoxy Adhesives Structural Adhesives Flexible Epoxy Adhesives Specialty Epoxy Formulations |

| By End-User Industry | Automotive & Transportation Construction & Infrastructure Aerospace & Defense Electronics & Electrical Equipment Renewable Energy (Wind, Solar) Marine & Offshore |

| By Application | Structural Bonding Assembly & Component Bonding Coatings & Encapsulation Potting & Sealing |

| By Distribution Channel | Direct Sales to OEMs Authorized Distributors & Resellers Online & E-Commerce Channels Specialized Retail Partners |

| By Country/Region | Saudi Arabia UAE Qatar Kuwait Oman Bahrain Israel |

| By Packaging Type | Cartridges & Dual-Cartridge Systems Drums & Bulk Containers Small Tubes & Consumer Packaging Custom Industrial Packaging |

| By Price Positioning | Economy/Commodity Grade Mid-Range Performance Premium/Specialized Formulations |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Construction Industry Applications | 45 | Project Managers, Site Engineers |

| Automotive Manufacturing Sector | 38 | Production Supervisors, Quality Control Managers |

| Electronics Assembly Processes | 35 | Manufacturing Engineers, Product Development Managers |

| Adhesive Distribution Channels | 28 | Sales Directors, Supply Chain Managers |

| Research & Development in Adhesives | 24 | R&D Scientists, Technical Directors |

The Middle East Epoxy Adhesives Market is valued at approximately USD 1.1 billion, driven by demand from industries such as construction, automotive, and electronics, which favor epoxy adhesives for their superior bonding strength and durability.