Region:Middle East

Author(s):Rebecca

Product Code:KRAD4960

Pages:93

Published On:December 2025

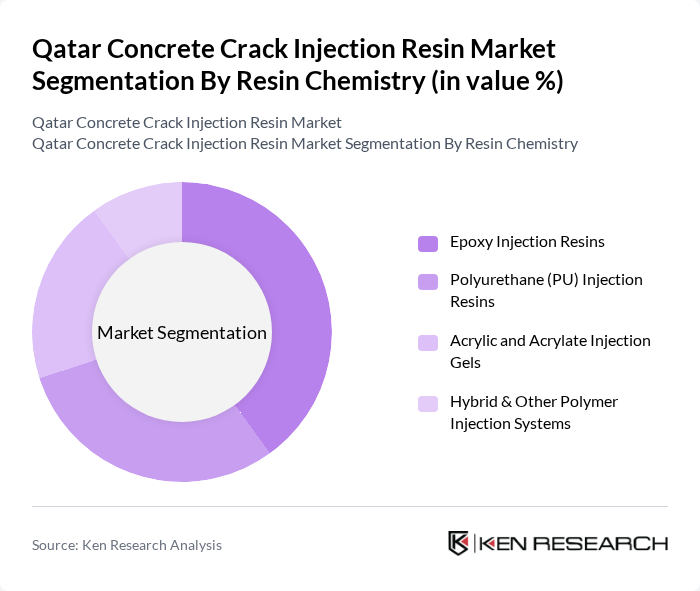

By Resin Chemistry:The market is segmented into four main types of resin chemistry: Epoxy Injection Resins, Polyurethane (PU) Injection Resins, Acrylic and Acrylate Injection Gels, and Hybrid & Other Polymer Injection Systems. Each of these subsegments serves different applications and offers unique properties that cater to various construction needs, such as high bond strength for structural stitching, flexible sealing in moving cracks, and low?viscosity systems for micro?crack penetration in aggressive environments.

The dominant subsegment in the resin chemistry category is Epoxy Injection Resins, which are favored for their superior bonding strength and durability in structural crack repair, including beams, slabs, columns, and foundations. These resins are widely used in structural applications due to their excellent mechanical properties, strong adhesion to concrete, and resistance to chemicals, chlorides, and moisture ingress in marine or coastal exposure conditions. The increasing focus on long-lasting, code-compliant repairs and asset life extension in infrastructure, oil and gas, marine works, and high?value buildings has led to a higher adoption of epoxy resins, making them a preferred choice among contractors, facility managers, and engineering consultants.

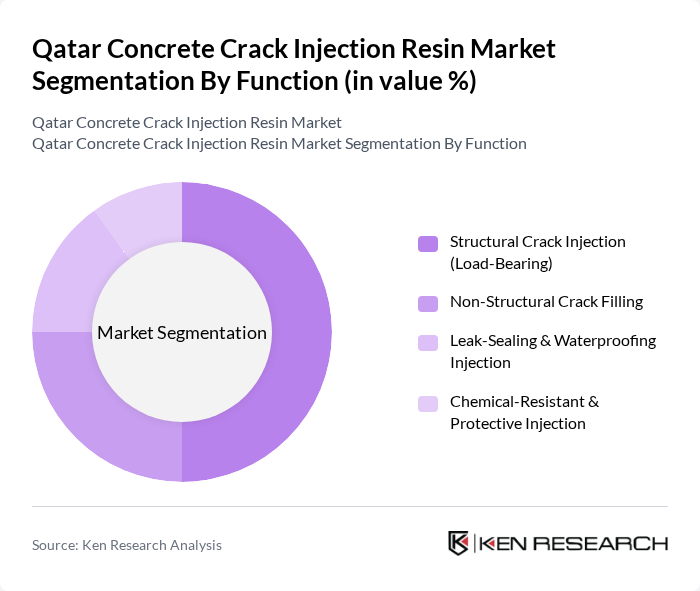

By Function:The market is also segmented based on function into Structural Crack Injection (Load-Bearing), Non-Structural Crack Filling, Leak-Sealing & Waterproofing Injection, and Chemical-Resistant & Protective Injection. Each function addresses specific needs in the repair and maintenance of concrete structures, ranging from structural stitching and reinstatement of load transfer to water cut?off in basements and tunnels, and lining protection in chemically aggressive process environments.

The leading subsegment in the function category is Structural Crack Injection (Load-Bearing), which is essential for maintaining the integrity of critical structures such as bridges, parking structures, podiums, industrial facilities, and high?rise buildings. This segment is driven by the increasing need for safety and serviceability in construction and asset management, as structural cracks can compromise the stability and durability of buildings and infrastructure if left untreated. The focus on stringent project specifications, quality control on repair works, and extending the service life of existing assets under Qatar National Vision 2030 has made this function a priority for consultants, contractors, and asset owners.

The Qatar Concrete Crack Injection Resin Market is characterized by a dynamic mix of regional and international players. Leading participants such as Sika AG, Mapei S.p.A., Fosroc International Ltd, Master Builders Solutions, BASF SE, Saint-Gobain Weber, The Euclid Chemical Company, GCP Applied Technologies, RPM International Inc. (including Tremco), Hilti Corporation, Simpson Strong-Tie Company Inc., Adhesives Technology Corporation, W. R. Meadows, Inc., Pidilite Industries Ltd, ITW Performance Polymers contribute to innovation, geographic expansion, and service delivery in this space, offering epoxy and polyurethane crack injection systems, repair mortars, protective coatings, and integrated waterproofing solutions tailored to Middle East climatic and exposure conditions.

The future of the Qatar concrete crack injection resin market appears promising, driven by ongoing infrastructure projects and a growing emphasis on sustainable construction practices. As the government continues to invest in smart city initiatives, the demand for advanced repair solutions is expected to rise. Additionally, the integration of digital technologies in construction will likely enhance the efficiency of resin applications, further propelling market growth and innovation in the coming years.

| Segment | Sub-Segments |

|---|---|

| By Resin Chemistry | Epoxy Injection Resins Polyurethane (PU) Injection Resins Acrylic and Acrylate Injection Gels Hybrid & Other Polymer Injection Systems |

| By Function | Structural Crack Injection (Load-Bearing) Non-Structural Crack Filling Leak-Sealing & Waterproofing Injection Chemical-Resistant & Protective Injection |

| By Crack & Substrate Characteristics | Dry Cracks Damp / Wet Cracks Moving / Dynamic Cracks Static Cracks |

| By Curing / Reaction Profile | Ultra-Fast / Rapid-Set Systems (< 30 minutes) Standard Curing Systems (30 minutes – 4 hours) Slow / Deep-Penetration Systems (> 4 hours) |

| By Delivery & Packaging Format | Dual-Cartridge / Cartridge Systems Bulk Packaging (Pails / Drums / IBCs) Pre-Proportioned Injection Kits Others |

| By Distribution Channel | Direct Sales to Contractors & Applicators Construction Chemical Distributors / Dealers Builder’s Merchants & Trade Retail Online & Project-Based Sales |

| By End-Use Sector | Buildings (Residential & Commercial) Industrial Facilities Infrastructure (Bridges, Tunnels, Roads, Ports) Oil & Gas, Utilities and Public Sector Assets |

| By Region | Doha Al Rayyan Al Wakrah Other Municipalities (Al Khor, Umm Salal, Al Daayen, Al Shamal) |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Residential Construction Projects | 120 | Project Managers, Site Engineers |

| Commercial Building Maintenance | 90 | Facility Managers, Maintenance Supervisors |

| Infrastructure Repair Initiatives | 80 | Public Works Officials, Civil Engineers |

| Specialty Contractors in Concrete Repair | 70 | Business Owners, Technical Directors |

| Suppliers of Construction Chemicals | 100 | Sales Managers, Product Development Leads |

The Qatar Concrete Crack Injection Resin Market is valued at approximately USD 140 million, reflecting its significance within the broader Middle East construction chemicals and concrete repair markets, driven by infrastructure development and maintenance needs.