Region:North America

Author(s):Geetanshi

Product Code:KRAA1203

Pages:100

Published On:August 2025

By Type:The market is segmented into Industrial Control Systems and Field Devices. The Industrial Control Systems segment includes various sub-segments such as Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), Supervisory Control and Data Acquisition (SCADA), Product Lifecycle Management (PLM), Manufacturing Execution Systems (MES), Human-Machine Interfaces (HMI), and Other Industrial Control Systems. The Field Devices segment encompasses Machine Vision, Industrial Robots, Motors and Drives, Safety Systems, Sensors and Transmitters, and Other Field Devices .

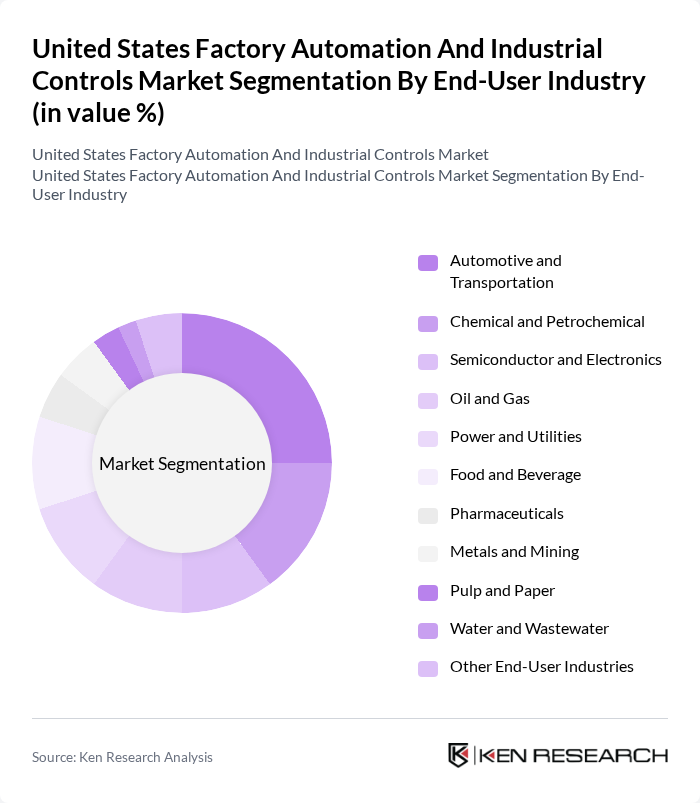

By End-User Industry:The market is segmented into various end-user industries including Automotive and Transportation, Chemical and Petrochemical, Semiconductor and Electronics, Oil and Gas, Power and Utilities, Food and Beverage, Pharmaceuticals, Metals and Mining, Pulp and Paper, Water and Wastewater, and Other End-User Industries. Each of these industries utilizes factory automation and industrial controls to enhance productivity and efficiency. Automotive and Transportation, Chemical and Petrochemical, and Semiconductor and Electronics remain the leading adopters, driven by the need for high-volume, precision manufacturing and stringent quality standards .

The United States Factory Automation And Industrial Controls Market is characterized by a dynamic mix of regional and international players. Leading participants such as Siemens AG, Rockwell Automation, Inc., Schneider Electric SE, Honeywell International Inc., Mitsubishi Electric Corporation, ABB Ltd., Emerson Electric Co., Yokogawa Electric Corporation, Bosch Rexroth AG, Omron Corporation, Fanuc Corporation, National Instruments Corporation, Beckhoff Automation GmbH & Co. KG, B&R Industrial Automation GmbH, KUKA AG, General Electric Company (GE Digital), ABB Inc. (US), Schneider Electric USA, Inc., Honeywell Process Solutions, Parker Hannifin Corporation contribute to innovation, geographic expansion, and service delivery in this space .

The future of the United States factory automation and industrial controls market appears promising, driven by ongoing technological advancements and a growing emphasis on efficiency. As industries increasingly adopt smart manufacturing practices, the integration of IoT and AI technologies will enhance operational capabilities. Furthermore, government initiatives aimed at promoting automation will likely provide additional support, fostering innovation and investment in this sector. The focus on sustainability will also shape future developments, encouraging eco-friendly automation solutions.

| Segment | Sub-Segments |

|---|---|

| By Type | Industrial Control Systems Distributed Control Systems (DCS) Programmable Logic Controllers (PLC) Supervisory Control and Data Acquisition (SCADA) Product Lifecycle Management (PLM) Manufacturing Execution Systems (MES) Human-Machine Interfaces (HMI) Other Industrial Control Systems Field Devices Machine Vision Industrial Robots Motors and Drives Safety Systems Sensors and Transmitters Other Field Devices |

| By End-User Industry | Automotive and Transportation Chemical and Petrochemical Semiconductor and Electronics Oil and Gas Power and Utilities Food and Beverage Pharmaceuticals Metals and Mining Pulp and Paper Water and Wastewater Other End-User Industries |

| By Component | Hardware Software Services |

| By Application | Manufacturing Execution Systems (MES) Supply Chain Management Quality Control Inventory Management |

| By Sales Channel | Direct Sales Distributors Online Sales |

| By Distribution Mode | Offline Distribution Online Distribution |

| By Price Range | Low-End Products Mid-Range Products High-End Products |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Automotive Manufacturing Automation | 100 | Production Managers, Automation Engineers |

| Food Processing Control Systems | 80 | Quality Assurance Managers, Operations Directors |

| Electronics Assembly Line Automation | 90 | Supply Chain Managers, Technical Directors |

| Pharmaceutical Manufacturing Controls | 70 | Regulatory Affairs Managers, Process Engineers |

| Textile Industry Automation Solutions | 60 | Production Supervisors, R&D Managers |

The United States Factory Automation and Industrial Controls Market is valued at approximately USD 47 billion, reflecting significant growth driven by the increasing demand for automation in manufacturing processes and the integration of advanced technologies like IoT and AI.