Region:Global

Author(s):Shubham

Product Code:KRAA2729

Pages:93

Published On:August 2025

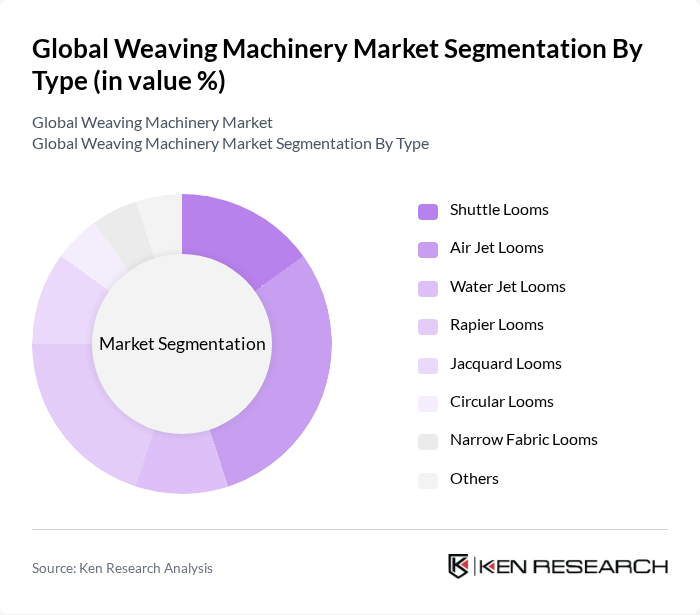

By Type:The weaving machinery market is segmented into Shuttle Looms, Air Jet Looms, Water Jet Looms, Rapier Looms, Jacquard Looms, Circular Looms, Narrow Fabric Looms, and Others.Air Jet Loomsare gaining significant traction due to their high-speed operation, energy efficiency, and ability to produce high-quality fabrics at scale. Manufacturers increasingly prefer air jet looms to meet the demand for diverse textiles, especially in fast fashion and technical textiles. The versatility of these looms in handling various yarns and fabric types further enhances their market appeal.

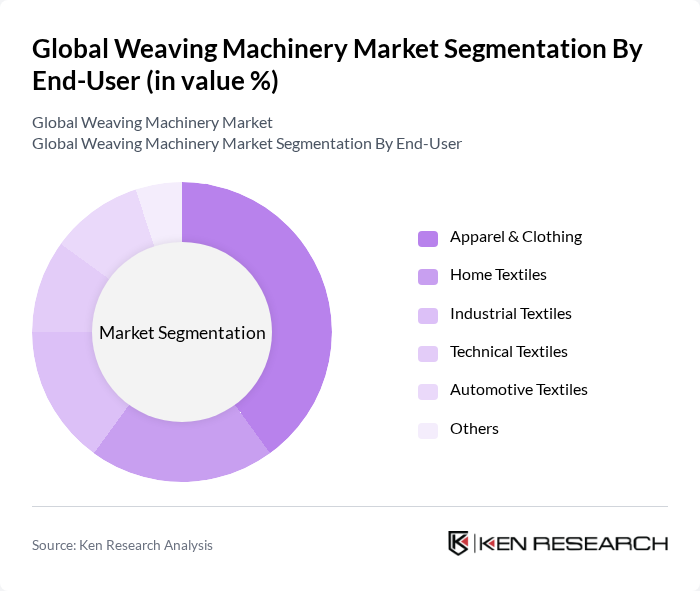

By End-User:The end-user segmentation includes Apparel & Clothing, Home Textiles, Industrial Textiles, Technical Textiles, Automotive Textiles, and Others. TheApparel & Clothingsegment is the largest end-user, driven by sustained demand for fashion and clothing products, especially in fast fashion and branded retail. The sector’s need for rapid turnaround and diverse fabric types has accelerated the adoption of advanced weaving technologies, including automated and high-speed looms. Technical and industrial textiles are also growing, supported by demand in automotive, medical, and protective applications.

The Global Weaving Machinery Market is characterized by a dynamic mix of regional and international players. Leading participants such as TMT Machinery Co., Ltd., Picanol N.V., Toyota Industries Corporation, Lindauer DORNIER GmbH, Tsudakoma Corporation, Itema S.p.A., Saurer AG, Zhejiang Rifa Textile Machinery Co., Ltd., Jingwei Textile Machinery Co., Ltd., Liba Maschinenfabrik GmbH, Benninger AG, H. Stoll AG & Co. KG, A. Monforts Textilmaschinen GmbH & Co. KG, Karl Mayer Textilmaschinenfabrik GmbH, SSM Schärer Schweiter Mettler AG contribute to innovation, geographic expansion, and service delivery in this space.

The future of the weaving machinery market appears promising, driven by ongoing technological advancements and a growing emphasis on sustainability. As manufacturers increasingly adopt smart technologies and automation, the efficiency of production processes is expected to improve significantly. Additionally, the rising demand for eco-friendly fabrics will likely spur innovation in machinery design, aligning with global sustainability goals. This convergence of technology and environmental consciousness will shape the market landscape, fostering growth and new opportunities in the coming years.

| Segment | Sub-Segments |

|---|---|

| By Type | Shuttle Looms Air Jet Looms Water Jet Looms Rapier Looms Jacquard Looms Circular Looms Narrow Fabric Looms Others |

| By End-User | Apparel & Clothing Home Textiles Industrial Textiles Technical Textiles Automotive Textiles Others |

| By Application | Fashion Fabrics Upholstery Automotive Textiles Medical Textiles Sportswear Others |

| By Distribution Channel | Direct Sales Online Retail Distributors Trade Shows Others |

| By Region | Asia-Pacific Europe North America Latin America Middle East & Africa |

| By Price Range | Low-End Mid-Range High-End |

| By Technology | Conventional Weaving Automated Weaving Smart Weaving Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Shuttle Weaving Machinery | 100 | Production Managers, Machinery Operators |

| Shuttleless Weaving Technology | 90 | Technical Directors, R&D Managers |

| Textile Machinery Suppliers | 75 | Sales Executives, Product Managers |

| Emerging Weaving Technologies | 50 | Innovation Officers, Industry Analysts |

| Market Trends in Weaving Machinery | 80 | Market Researchers, Business Development Managers |

The Global Weaving Machinery Market is valued at approximately USD 6.4 billion, reflecting a significant growth trend driven by increasing demand for textiles across various sectors, including apparel, automotive, and home furnishings.