Region:Middle East

Author(s):Rebecca

Product Code:KRAD2759

Pages:97

Published On:November 2025

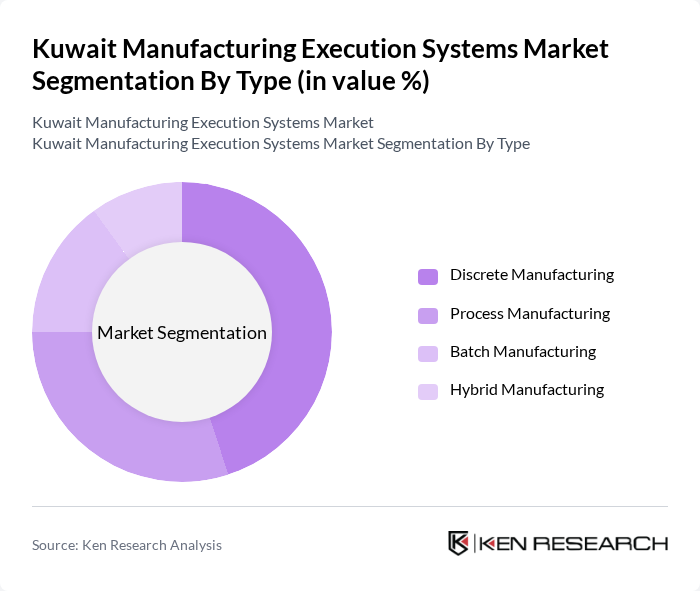

By Type:The Manufacturing Execution Systems market is segmented into Discrete Manufacturing, Process Manufacturing, Batch Manufacturing, and Hybrid Manufacturing. Discrete Manufacturing leads the market, driven by its widespread application in automotive and electronics industries, where precise production control and traceability are critical. The increasing complexity of manufacturing operations and the demand for product customization are accelerating the adoption of Discrete Manufacturing systems .

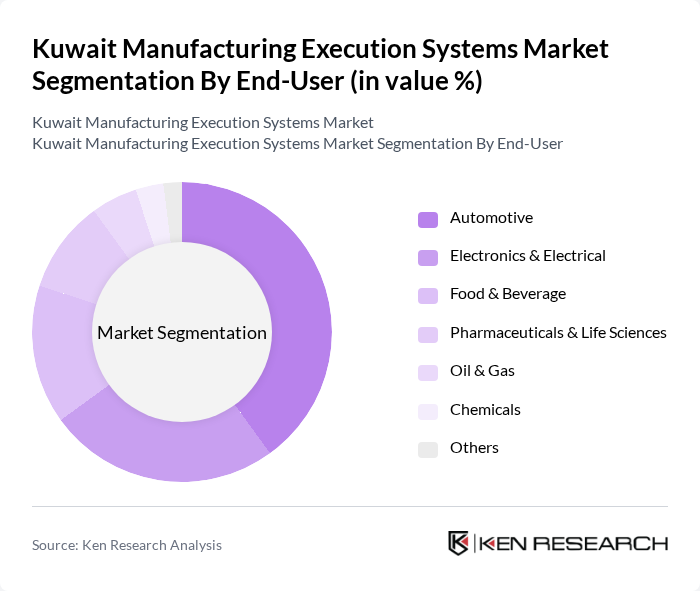

By End-User:The end-user segmentation includes Automotive, Electronics & Electrical, Food & Beverage, Pharmaceuticals & Life Sciences, Oil & Gas, Chemicals, and Others. The Automotive sector is the largest contributor, propelled by the need for enhanced production efficiency, stringent quality control, and the growing adoption of electric vehicles and smart manufacturing solutions. Electronics and life sciences are also significant, reflecting the broader trend toward digitalization and compliance-driven manufacturing .

The Kuwait Manufacturing Execution Systems Market is characterized by a dynamic mix of regional and international players. Leading participants such as Siemens AG, Rockwell Automation, Inc., Schneider Electric SE, Honeywell International Inc., ABB Ltd., GE Digital (General Electric Company), Mitsubishi Electric Corporation, Yokogawa Electric Corporation, Dassault Systèmes SE, PTC Inc., Oracle Corporation, SAP SE, Infor, QAD Inc., Plex Systems, Inc., Aspen Technology, Inc., Emerson Electric Co., AVEVA Group plc, Schneider Electric (Wonderware), Siemens (Opcenter) contribute to innovation, geographic expansion, and service delivery in this space.

The future of the Kuwait manufacturing execution systems market appears promising, driven by technological advancements and a growing emphasis on digital transformation. As manufacturers increasingly adopt smart technologies, the integration of IoT and AI will enhance operational efficiency and decision-making. Furthermore, government support for innovation and sustainability initiatives will likely foster a conducive environment for growth, enabling manufacturers to leverage advanced systems to remain competitive in the global market.

| Segment | Sub-Segments |

|---|---|

| By Type | Discrete Manufacturing Process Manufacturing Batch Manufacturing Hybrid Manufacturing |

| By End-User | Automotive Electronics & Electrical Food & Beverage Pharmaceuticals & Life Sciences Oil & Gas Chemicals Others |

| By Industry Vertical | Aerospace & Defense Chemicals & Petrochemicals Consumer Packaged Goods Metals & Mining Energy & Utilities Others |

| By Deployment Model | On-Premises Cloud-Based Hybrid |

| By Functionality | Production Management Quality Management Inventory Management Maintenance Management Scheduling & Dispatching Track & Trace Others |

| By Region | Central Kuwait Northern Kuwait Southern Kuwait Others |

| By Policy Support | Government Subsidies Tax Incentives Regulatory Support Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Oil & Gas Manufacturing | 45 | IT Managers, Operations Directors |

| Food Processing Sector | 38 | Production Managers, Quality Assurance Heads |

| Textile Manufacturing | 32 | Supply Chain Managers, Plant Managers |

| Electronics Manufacturing | 42 | Engineering Managers, IT Specialists |

| Pharmaceutical Manufacturing | 28 | Regulatory Affairs Managers, Production Supervisors |

The Kuwait Manufacturing Execution Systems Market is valued at approximately USD 110 million, reflecting a five-year historical analysis. This growth is driven by the increasing adoption of industrial automation and the demand for operational efficiency across various manufacturing sectors.