Region:Global

Author(s):Dev

Product Code:KRAB2204

Pages:95

Published On:January 2026

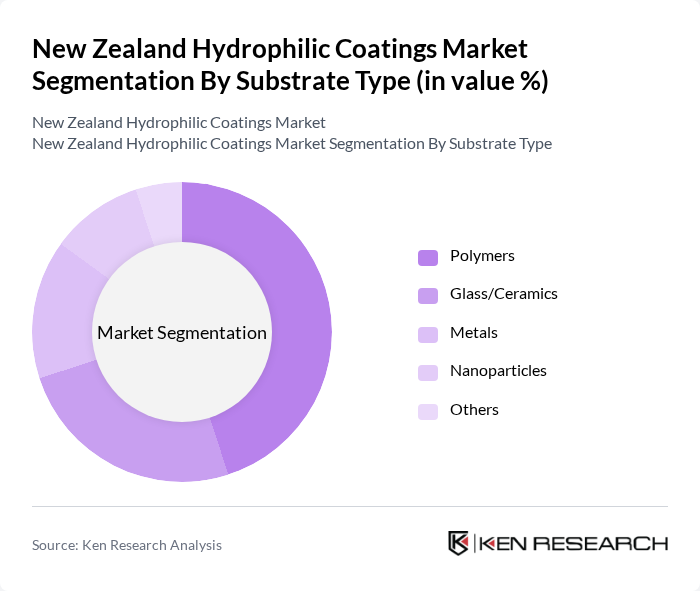

By Substrate Type:The substrate type segmentation includes various materials used for hydrophilic coatings, which are essential for different applications. The subsegments are Polymers, Glass/Ceramics, Metals, Nanoparticles, and Others. Among these, Polymers are the leading subsegment due to their versatility, lightweight nature, and excellent adhesion properties, making them ideal for medical devices and consumer products. Nanoparticle?enabled coatings are also gaining share globally because they can significantly enhance corrosion resistance, durability, and wetting performance across metals and glass, and similar performance-driven adoption is gradually influencing substrate choices in New Zealand for high?value applications.

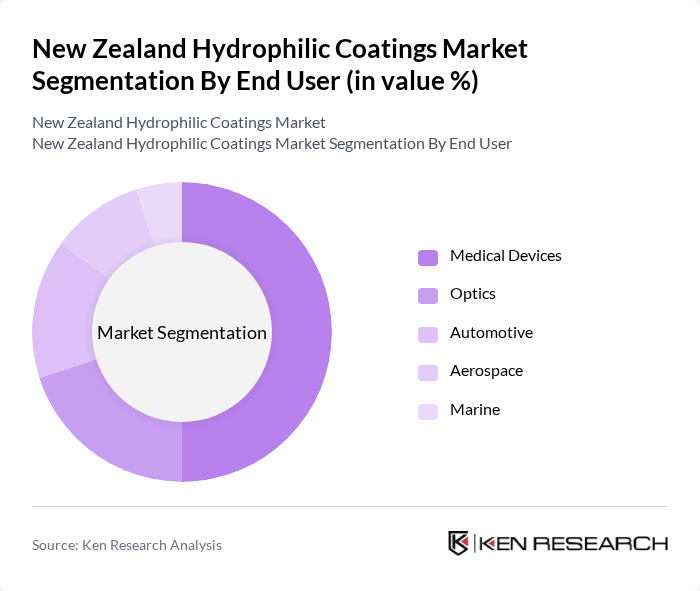

By End User:The end-user segmentation encompasses various industries utilizing hydrophilic coatings, including Medical Devices, Optics, Automotive, Aerospace, Marine, and Others. The Medical Devices segment is the most significant, in line with global trends where medical devices account for the largest share of hydrophilic coatings demand, driven by the increasing use of minimally invasive procedures and the need for lubricious, biocompatible surfaces on catheters, guidewires, and surgical tools. Optics and automotive applications are also important users, reflecting growing use of anti-fog and anti-contamination hydrophilic coatings on lenses, windshields, and camera systems.

The New Zealand Hydrophilic Coatings Market is characterized by a dynamic mix of regional and international players. Leading participants such as Aculon Inc., Surmodics Inc., Hydromer Inc., Harland Medical Systems Inc., Biocoat Inc., Surface Solutions Group LLC, Koninklijke DSM N.V., Teleflex Incorporated, AST Products Inc., Specialty Coating Systems Inc., 3M Company, PPG Industries Inc., AkzoNobel N.V., BASF SE, Covestro AG contribute to innovation, geographic expansion, and service delivery in this space.

The future of the hydrophilic coatings market in New Zealand appears promising, driven by technological advancements and increasing applications across various sectors. The focus on sustainability is expected to propel the development of eco-friendly coatings, aligning with global environmental goals. Additionally, the integration of smart technologies in coatings will likely enhance functionality, catering to the evolving needs of industries. As awareness grows, the market is poised for significant expansion, supported by ongoing research and development efforts aimed at innovative applications.

| Segment | Sub-Segments |

|---|---|

| By Substrate Type | Polymers Glass/Ceramics Metals Nanoparticles Others |

| By End User | Medical Devices Optics Automotive Aerospace Marine Others |

| By Application | Catheters and Guidewires Intraocular and Contact Lenses Optical Lenses, Prisms, and Mirrors Automotive Glass and Exterior Components Marine and Aerospace Components Others |

| By Region (Within New Zealand) | North Island South Island |

| By Performance Attribute | Level of Hydrophilicity / Wetting Angle Durability / Wear Resistance Chemical and Temperature Resistance Antifog / Anti-reflective Performance Others |

| By Sales / Distribution Channel | Direct Sales to OEMs Distributors and Coating Service Providers Online / Digital Sales Others |

| By Customer Type | Medical Device OEMs Industrial & Automotive OEMs Optical Labs & Lens Manufacturers Contract Coaters / Job Shops Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Healthcare Applications | 120 | Medical Device Manufacturers, Product Development Managers |

| Automotive Coatings | 90 | Automotive Coatings Engineers, Procurement Specialists |

| Electronics Industry | 80 | Electronics Manufacturers, Quality Assurance Managers |

| Textile Coatings | 70 | Textile Manufacturers, R&D Directors |

| Research Institutions | 60 | Academics, Coating Technology Researchers |

The New Zealand Hydrophilic Coatings Market is valued at approximately USD 3540 million, driven by demand in sectors such as medical devices, automotive, and aerospace, which require advanced surface properties for enhanced performance.