Region:Asia

Author(s):Rebecca

Product Code:KRAE2873

Pages:100

Published On:February 2026

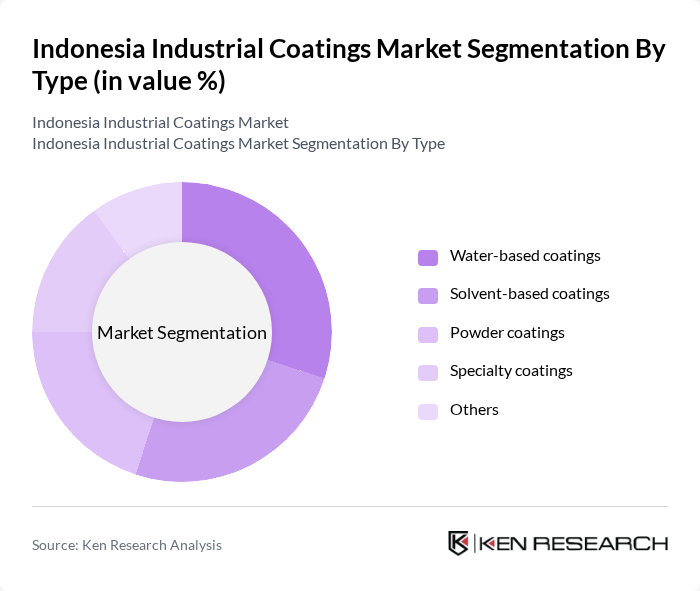

By Type:The market is segmented into various types of coatings, including water-based coatings, solvent-based coatings, powder coatings, specialty coatings, and others. Water-based coatings are gaining traction due to their eco-friendliness and lower VOC emissions, while solvent-based coatings remain popular for their durability and performance in industrial applications. Powder coatings are increasingly favored for their efficiency and environmental benefits, making them a significant player in the market.

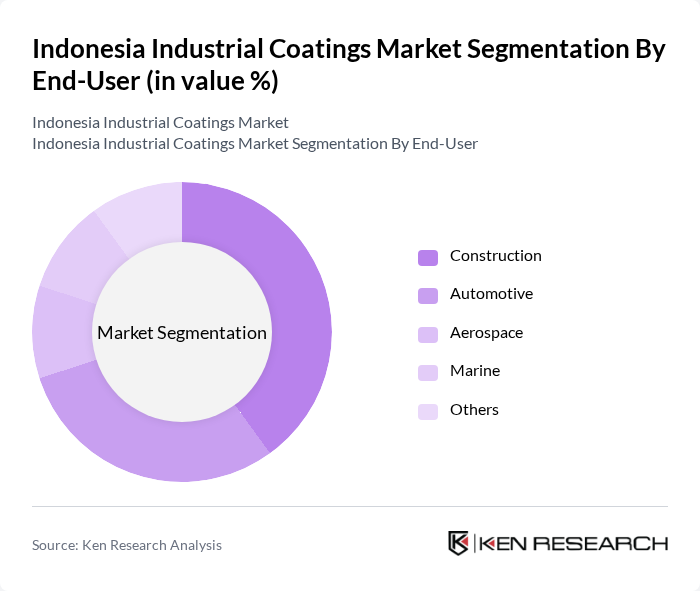

By End-User:The industrial coatings market is further segmented by end-user industries, including construction, automotive, aerospace, marine, and others. The construction sector is the largest consumer of industrial coatings, driven by ongoing infrastructure projects and urban development. The automotive industry also plays a crucial role, with increasing vehicle production and demand for high-performance coatings.

The Indonesia Industrial Coatings Market is characterized by a dynamic mix of regional and international players. Leading participants such as PT. PPG Coatings Indonesia, PT. Nippon Paint Indonesia, PT. AkzoNobel Indonesia, PT. Jotun Indonesia, PT. BASF Indonesia, PT. Sika Indonesia, PT. Asian Paints Indonesia, PT. Sherwin-Williams Indonesia, PT. Hempel Indonesia, PT. Tikkurila Indonesia, PT. Dulevo Indonesia, PT. Mowilex Indonesia, PT. Dulux Indonesia, PT. Ceresit Indonesia, PT. Valspar Indonesia contribute to innovation, geographic expansion, and service delivery in this space.

The future of the Indonesia industrial coatings market appears promising, driven by technological advancements and a shift towards sustainable practices. As manufacturers increasingly adopt low-VOC and eco-friendly coatings, the market is likely to witness a transformation in product offerings. Additionally, the ongoing investments in infrastructure and automotive sectors will further bolster demand, creating a favorable environment for growth. Companies that innovate and adapt to regulatory changes will be well-positioned to capitalize on emerging opportunities in this evolving landscape.

| Segment | Sub-Segments |

|---|---|

| By Type | Water-based coatings Solvent-based coatings Powder coatings Specialty coatings Others |

| By End-User | Construction Automotive Aerospace Marine Others |

| By Application | Protective coatings Decorative coatings Industrial coatings Automotive coatings Others |

| By Distribution Channel | Direct sales Distributors Online sales Retail Others |

| By Region | Java Sumatra Kalimantan Sulawesi Others |

| By Technology | Conventional technology Advanced technology Eco-friendly technology Others |

| By Product Formulation | Acrylic coatings Alkyd coatings Epoxy coatings Polyurethane coatings Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Automotive Coatings | 100 | Production Managers, Quality Control Supervisors |

| Construction Coatings | 80 | Project Managers, Procurement Officers |

| Industrial Equipment Coatings | 70 | Operations Managers, Technical Directors |

| Protective Coatings | 60 | Safety Officers, Product Development Managers |

| Marine Coatings | 50 | Fleet Managers, Maintenance Supervisors |

The Indonesia Industrial Coatings Market is valued at approximately USD 1.5 billion, driven by growth in the construction and automotive sectors, as well as increasing demand for eco-friendly coatings.