Region:Asia

Author(s):Shubham

Product Code:KRAD3062

Pages:81

Published On:January 2026

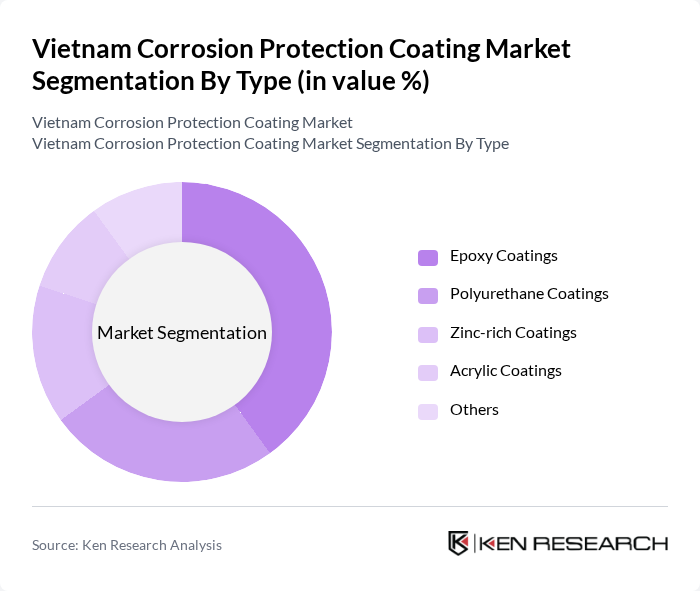

By Type:The corrosion protection coating market can be segmented into various types, including Epoxy Coatings, Polyurethane Coatings, Zinc-rich Coatings, Acrylic Coatings, and Others. Among these, epoxy coatings are the most widely used due to their excellent adhesion, chemical resistance, and durability, making them suitable for a variety of applications. Polyurethane coatings are also gaining traction due to their flexibility and UV resistance, while zinc-rich coatings are preferred for their anti-corrosive properties in industrial applications.

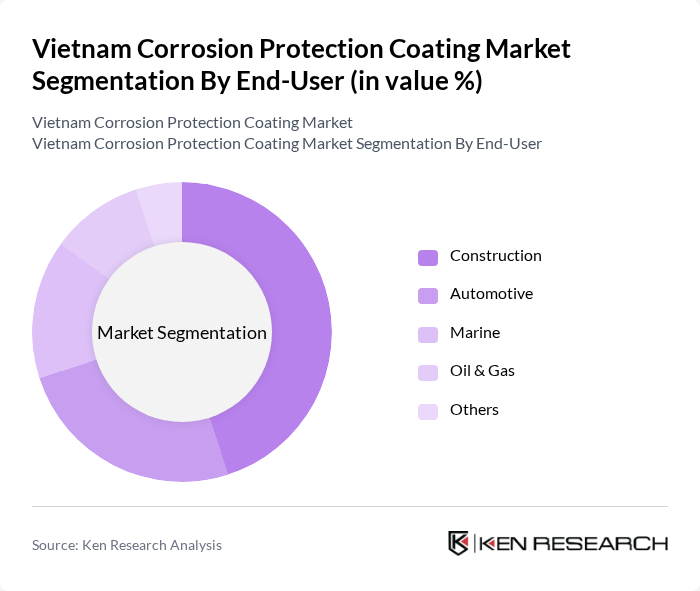

By End-User:The end-user segmentation includes Construction, Automotive, Marine, Oil & Gas, and Others. The construction sector is the leading end-user of corrosion protection coatings, driven by the increasing number of infrastructure projects and the need for durable materials. The automotive industry also significantly contributes to the market, as manufacturers seek coatings that enhance vehicle longevity and performance. The marine sector is growing due to the need for protective coatings in shipbuilding and maintenance.

The Vietnam Corrosion Protection Coating Market is characterized by a dynamic mix of regional and international players. Leading participants such as Jotun Vietnam, AkzoNobel Vietnam, PPG Industries Vietnam, Hempel Vietnam, BASF Vietnam, Sherwin-Williams Vietnam, Nippon Paint Vietnam, Tikkurila Vietnam, Asian Paints Vietnam, RPM International Inc., Sika Vietnam, Berger Paints Vietnam, DuraCoat Vietnam, Valspar Vietnam, KCC Corporation Vietnam contribute to innovation, geographic expansion, and service delivery in this space.

The Vietnam corrosion protection coating market is poised for significant growth, driven by increasing industrial activities and a focus on sustainable practices. As the government invests in infrastructure and urban development, the demand for advanced coatings will rise. Additionally, technological innovations, such as the integration of nanotechnology, will enhance coating performance. Companies that adapt to these trends and prioritize eco-friendly solutions will likely capture a larger market share, positioning themselves favorably in the evolving landscape.

| Segment | Sub-Segments |

|---|---|

| By Type | Epoxy Coatings Polyurethane Coatings Zinc-rich Coatings Acrylic Coatings Others |

| By End-User | Construction Automotive Marine Oil & Gas Others |

| By Application | Industrial Equipment Infrastructure Transportation Power Generation Others |

| By Distribution Channel | Direct Sales Distributors Online Sales Retail Others |

| By Region | Northern Vietnam Southern Vietnam Central Vietnam Others |

| By Product Formulation | Water-based Coatings Solvent-based Coatings Powder Coatings Others |

| By Market Segment | Commercial Residential Industrial Government Others |

| Scope Item/Segment | Sample Size | Target Respondent Profiles |

|---|---|---|

| Construction Industry Coating Applications | 100 | Project Managers, Site Engineers |

| Marine Coating Solutions | 80 | Marine Engineers, Fleet Managers |

| Oil & Gas Sector Coating Needs | 70 | Maintenance Supervisors, Safety Officers |

| Manufacturing Sector Corrosion Challenges | 90 | Production Managers, Quality Control Inspectors |

| Infrastructure Development Coating Requirements | 60 | Urban Planners, Civil Engineers |

The Vietnam Corrosion Protection Coating Market is valued at approximately USD 25 million, driven by rapid industrialization, urbanization, and significant investments in infrastructure and construction projects across the country.